All industries

Below you will find information on all recent serious incidents and safety information to help protect you and your workplace.

Agriculture

Workers exposed to hazardous chemicals (2 December 2024)

A 64-year-old cellar hand was performing routine duties at a winery. While preparing a batch of ‘brewer water’, a reaction occurred when Ammonium Bisulphite (ABS) and Tartaric Acid combined. This released hazardous sulphur dioxide and ammonia gas into the atmosphere. The fumes affected the cellar hand immediately. It also affected six other workers who experienced respiratory issues.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with the use of hazardous chemicals.

Assess and eliminate or control risks

Ensure:

- you are familiar with the ‘Managing risks of hazardous chemicals in the Workplace - Code of Practice’ which provides guidance on how to manage the risks associated with hazardous chemicals

- the manufacturer/importer’s information provided in the Safety Data Sheet (SDS) is available

- the SDS contains relevant information for guidance on managing risks of the hazardous chemical, such as:

- hazards of the hazardous chemical

- control measures for first aid, firefighting, accidental release and safe handling and storage

- control measures to minimise exposure to workers

- conditions to avoid in storage handling

- potential incompatible products

- you maintain and monitor chemical storage containers and systems to ensure they are fit for purpose.

Develop and implement safe systems of work

When the risks of hazardous chemicals cannot be eliminated, you should:

- substitute hazardous chemicals for safer options where possible and consider their physical form, properties and concentration

- design systems to eliminate the risk of inadvertent mixing or interactions of incompatible chemicals

- ensure suitable storage facilities are provided and maintained e.g. isolation/segregates chemicals, extraction/ventilation, temperature management, bunded and protected from impact

- manage exposure standards of each hazardous chemical

- develop and implement documented procedures and make them available to workers (these should be developed with reference to the product’s safety data sheet)

- train workers in the proper handling and storage of chemicals, make them aware of the risks, and explain what to do if a leak, chemical reaction or exposure happens

- supervise workers when they are handling or storing hazardous chemicals

- regularly review and revise (as necessary) control measures to ensure they remain effective.

Ensure information is available for the storage and handling of chemicals by:

- clearly labelling all hazardous chemicals

- keeping a register that lists all the hazardous chemicals used, stored and handled in the workplace. This register must include the current safety data sheet for each chemical listed and must be available to everyone who may be affected by the hazardous chemicals

- displaying placards with information about the hazardous chemical to assist emergency services if stored hazardous chemicals exceed the ‘placard quantity’

- displaying safety signs near chemical handling and storage areas where required

- ensuring chemical storage containers and systems are maintained and monitored so they are fit for purpose

- ensuring fire extinguishers, suitable fire protection and firefighting equipment are available in areas where chemicals are used and stored.

Plan for emergencies

You should:

- have an emergency plan and first aid plan in place

- train staff in the emergency plan and first aid plan

- consult workers about the emergency plan and safety management system

- provide and clearly identity spill kits to manage any spills and leaks

- monitor workers’ health through a registered medical practitioner if they are likely to be exposed to hazardous chemicals

- immediately notify SafeWork NSW if a notifiable incident occurs

- immediately notify emergency services if a spill, leak or exposure occurs.

Related guidance material

- Code of Practice - Managing risks of hazardous chemicals in the workplace (PDF, 1171.43 KB)

- Code of Practice - Labelling of workplace hazardous chemicals (PDF, 1176.83 KB)

- Code of Practice - How to manage work health and safety risks (PDF, 556.72 KB)

- Hazardous chemicals - General requirements

- Placarding for storage of hazardous chemicals

Further information

Worker injured during agricultural irrigation installation (21 November 2024)

A 24-year-old male worker was undertaking labouring duties for the installation of a new agricultural irrigation system at a farm site when he was tasked with ‘flushing’ the newly installed poly irrigation lines. Whilst undoing the clamps housing the pump filter, a solid plastic cap shot upwards under significant pressure, striking him in the mouth and nose area. He sustained substantial facial injuries.

Image of filter/pump being worked on. Clamps/bolts were being removed from the green sleeve clamp at the top.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with working with pressurised pumps, and with workers from culturally and linguistically diverse backgrounds.

Ensure:

- work should be carried out by a suitably qualified irrigation technician / plumber

- workers are provided documentation on control measures for isolating energy to the plant and equipment when undertaking cleaning, servicing, repairing, or alteration

- workers receive adequate training and instruction in the correct use of plant

- competency systems are in place and validated prior to workers undertake high risk work

- procedures are translated to the appropriate dialects within your workplace

- appropriate supervision is in place for new workers during plant use and maintenance activities

- safe work procedures are implemented and followed by all workers

- the work environment and task are assessed for potential risks prior to work being undertaken

- workers wear adequate personal protective equipment (PPE)

- emergency plans are prepared, maintained and implemented.

Related guidance material

- Plant, Equipment and Machinery Energy Isolation Guidelines (PDF, 10885.87 KB)

- Code of Practice - Managing the risks of plant in the workplace (PDF, 1987.96 KB)

- SafeWork WHS Toolkit

- At Risk Workers

- Diversity in the workplace

- Pressurised pipe incident (29 November 2019)

Further information

Retired farmer crushed by hay bales (12 October 2024)

A 74-year-old retired farmer sustained fatal injuries when he was found under two hay bales weighing approximately 600kg each. The bales fell from a truck whilst being unloaded at a rural property in Rand NSW.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with unloading heavy loads using mobile plant.

Ensure:

- in consultation with workers involved in the loading and unloading process, a detailed traffic management plan including clearly defined exclusion zones and procedures is prepared before the loading and unloading of hay bales

- the traffic management plan is enforced, a clear line of site is maintained between all workers and the activity is stopped if the line of sight is compromised

- the exclusion zones are maintained around mobile plant and if other persons enter the loading and unloading area, work is stopped immediately

- specific control measures are in place to remove the risk associated with falling hay bales while loading and unloading is being undertaken. For example, ensure workers are not on the opposite side of a trailer where the hay bales are being loaded or unloaded.

- workers have the necessary training, experience and supervision to identify hazards and control the risks associated with unloading heavy loads and the general operation of mobile plant

- care is taken not to dislodge other bales – when lifting bales across the surface of the bale below, this can lead to stacks becoming unstable

- stacks are always stable and checked regularly for movement.

Related guidance material

- Code of Practice – Managing the risks of plant in the workplace (PDF, 1987.96 KB)

- Working with hay bales

- Safety around your vehicle glove box guide

- Equipment on farms

- Farm machinery Fact Sheet

- Safety around your tractor (PDF, 1674.31 KB)

Further information

Worker trapped under quad bike (30 September 2024)

An 82-year-old worker was undertaking farm work activities on a quad bike at a rural property near Moree in Northern NSW. The worker was found trapped under the quad bike that was rolled on its side. The worker sustained fatal injuries.

Photo shows the rolled quad bike at the location of the incident.

Safety Information

Consider ‘reasonably practicable’ control measures to manage the risks associated with quad bikes.

As a farm owner or farm operator you are responsible for anyone operating a quad bike at your workplace. You must identify the risks associated with quad bike use and do what you are reasonably able to do to eliminate those risks.

Ensure:

- you choose the right vehicle for the job

- an operator protective device (OPD) (also referred to as a crush protection device or roll bar) is installed when purchasing the vehicle and the device is maintained and never removed from the vehicle

- you protect your head and always wear a helmet

- tell someone where you are going and when you plan to return

- choose the safest route, look out for obstacles and consider the slope of the terrain

- if you cannot see what the ground conditions are like, get off and walk around the area before you drive over it

- regularly check the tyre pressures

- balance your load, keep it low and make sure it is securely strapped down

- follow load limits stated in the owner’s manual

- the rider is trained and capable to safely operate and maintain the quad bike

- no children under 16 rides on adult sized quad bikes – even as a passenger

- the quad bike is serviced and maintained as per the manufacturers owner’s manual.

Statistics

Quad bikes continue to be the biggest killer on Australian farms, with rollover the most common cause of death. Over 80% of quad bike fatalities in NSW are due to quad bike roll over.

Farm owners and operators must be aware that quad bikes are high risk vehicles and are not safe for use on all terrains or for all tasks.

Rollover can occur suddenly, even at low speeds and on flat terrain, putting the operator at risk of injury or death from being thrown from the vehicle, trapped, or crushed beneath it.

Related guidance material

- Code of Practice – Managing the risks of plant in the workplace (PDF, 1987.96 KB)

- Quad Bike safety

- Quad bikes & side-by-side vehicles

- Quad bikes and SSV training

- Farm vehicle pre-purchase checklist (PDF, 56.87 KB)

Further information

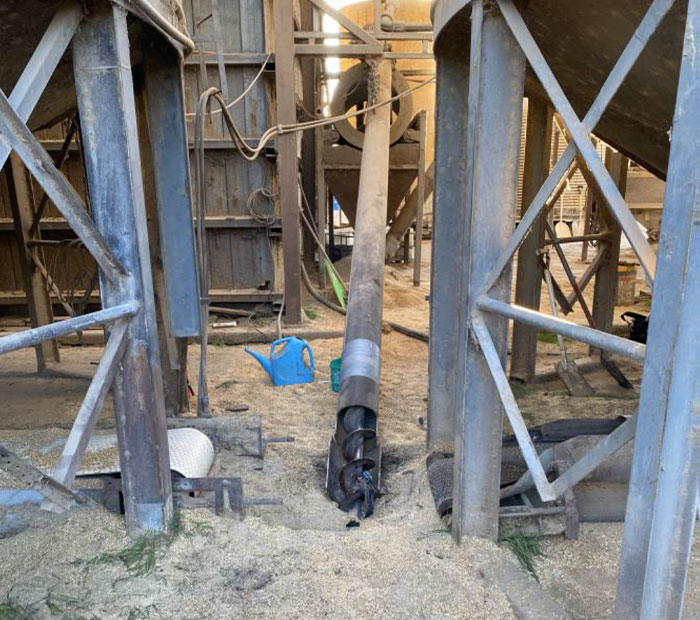

Worker seriously injured during auger maintenance (23 May 2024)

A 43-year-old worker was seriously injured whilst undertaking maintenance work on an auger. The worker’s hand became entangled and was partially amputated.

Safety information

Auger intakes and harvesting machinery can cause serious and fatal injuries if not used safely. Consider ‘reasonably practicable’ control measures to manage the risks associated with the use and maintenance of augers.

Install machine guarding

Ensure:

- all moving parts including, but not limited to, the auger screw, drive belts, pulleys, chains, sprockets and drive shafts are fully guarded, including back guarding to prevent contact from behind

- there is a correctly fitted intake guard installed

- at the infeed end of the auger, a permanently fixed inner guard is installed over the flight (screw). An outer guard should be installed over the auger’s flight when it is not being used in a silo, grain bin or a guarded hopper

- all machine guarding is compliant with Australian Standard AS 4024

- an emergency stop button is easily accessible near the auger inlet.

Implement and follow safe systems of work

Ensure:

- workers receive adequate training and instruction in the correct use of the machinery and auger

- workers are supervised during machinery use and maintenance activities

- safe work procedures are implemented and followed by all workers

- the auger is only used in line with the original manufacturer’s specifications

- the work environment and task are assessed for potential risks prior to work being undertaken

- when moving grain augers always check for overhead power lines

- an exclusion zone is enforced around the auger during use

- workers wear adequate personal protective equipment (PPE)

- emergency plans are prepared, maintained and implemented.

Perform regular maintenance

Ensure:

- the auger is inspected by a competent person prior to use. Any defects identified must be reported and rectified before use

- the auger is maintained in line with the original manufacturer’s specifications

- isolation and a lock out/tag out system is implemented when performing maintenance and cleaning and guards are replaced before the auger is restarted

- a suitable blockage clearing device that is designed for the purpose is provided. Do not use hands, feet or other objects to clear blockages.

Related guidance material

- Managing the risks of plant in the workplace - Code of Practice

- Plant, machinery and equipment

- Equipment on farms

- How to use machine guarding - SafeWork NSW YouTube

- Australian Standard AS 4024

Further information

- Traumatic event management plan – SafeWork NSW

- Speak Up Save Lives App – SafeWork NSW

- Mental health at work – NSW Government

- Subscribe to SafeWork NSW newsletters and updates

Side-by-side vehicles

Side-by-vehicles have been involved in several incidents resulting in serious injuries and fatalities. Using a correctly fitted seatbelt, wearing a helmet and closing the door or cab net could save your life.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with operating Side-by-side vehicles.

Ensure:

- you choose the right vehicle for the task and terrain

- operators have adequate information, training, instruction and supervision to safely operate and maintain the vehicle as well as understand the risks associated with using these vehicles

- seatbelts are worn (including passengers)

- helmets are worn (including passengers)

- doors / cab nets are closed

- only suitable attachments are used (follow manufacturers recommendations)

- safe operating procedures are followed (available from manufacturer)

- the key is removed and stored away from children when not in use

- the vehicle is regularly maintained and used in accordance with manufacturers’ instructions

- you never allow kids under 16 to operate an SSV

- you never exceed load limits

- you never carry passengers in the rear cargo tray.

Statistics

Since July 2023 there have been nine incidents involving side-by-side vehicles resulting in fatal or serious injuries.

Related guidance material

- Side-by-side vehicle fact sheet

- Quad bikes and side-by-side vehicles

- Side-by-side vehicle safety

- SSV Seat Belt Safety - YouTube

- Farm vehicle pre-purchase checklist

Further information

- Traumatic event management plan – SafeWork NSW

- Speak Up Save Lives App – SafeWork NSW

- Mental health at work – NSW Government

- Subscribe to SafeWork NSW newsletters and updates

Worker crushed by tandem drum roller (25 March 2024)

A 41-year-old worker was undertaking flood remediation work on an access road using a 2.5 tonne tandem drum roller to compact road base. As he was operating the roller on the slope parallel to the road the roller slid, partially crushing him as it turned over. The worker suffered severe crush injuries and was ejected approximately 5 metres from the overturned roller.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with using mobile plant.

Ensure:

- safe systems of work are established and maintained in relation to the use of mobile plant

- site conditions are assessed for potential hazards before commencing any work. For example, a competent person should assess ground conditions and put systems in place to eliminate or minimise (if not reasonably practicable to eliminate) the site-specific risks, so far as is reasonably practicable

- only mobile plant that is specifically designed for the work task is used

- operators are provided with information, training and instruction so they are competent in the correct use of the mobile plant

- mobile plant and machinery are only operated within the design limits as prescribed by the original equipment manufacturer (OEM)

- a safe system of work is developed and followed by all workers. The system of work must detail the:

- tasks to be performed

- how the tasks are to be performed

- the location of the tasks.

- suitable safety devices to protect operators are installed, used, and maintained. For example, seatbelts

- plant and machinery are inspected, tested and maintained in accordance with the manufacturer’s recommendations

- an emergency response plan is in place and has been specifically developed for the task

- mobile plant is securely stored when not in use to prevent unauthorised access or use.

Related guidance material

- Code of Practice: Managing the risks of plant in the workplace (PDF, 1987.96 KB)

- Code of Practice: How to manage work health and safety risks (PDF, 556.72 KB)

- Code of Practice: Managing the work environment and facilities (PDF, 422.29 KB)

- General guide for managing the risks of machinery in rural workplaces - Safe Work Australia

Further information

- Traumatic event management plan – SafeWork NSW

- Mental health at work – NSW Government

- Speak Up Save Lives App – SafeWork NSW

- Subscribe to SafeWork NSW newsletters and updates

Generator refuelling (11 December 2023)

A 20-year-old casual worker who was collecting and analysing grain samples became seriously injured when a newly purchased petrol-powered generator exploded. The explosion happened while the generator was being refuelled with a jerry can. The generator was expected to operate consistently for 14 hours and required refuelling about every 2 hours to constantly power a demountable office building and its equipment. The fire destroyed the generator and the demountable office building, and the young worker sustained severe burns to her face and body.

Photos of the burnt generator and demountable office building.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with generator refuelling.

Ensure:

- a risk assessment is undertaken to ensure control measures are in place to eliminate any heat and possible ignition sources and control the accumulation of flammable and combustible substances when refuelling

- prior to refuelling, the engine and all electrical equipment are turned off and the engine allowed to cool as per the manufacturer’s instructions

- you follow manufacturer's recommendations, and operating procedures

- you establish designated refuelling areas on firm ground or earth and in a well-ventilated location

- you have suitable firefighting equipment in good working order that is easily accessible

- you use approved fuel containers and funnels to reduce the risk of generating static electricity while decanting petrol

- you provide instruction, training and supervision to all workers on the safe use, storage and handling of hazardous chemicals

- you wear appropriate personal protective equipment for the task.

Related guidance material

Further information

- Traumatic event management plan – SafeWork NSW

- Mental health at work – NSW Government

- Speak Up Save Lives App – SafeWork NSW

- Subscribe to SafeWork NSW newsletters and updates

Young workers seriously injured in auger incidents (July and August 2023)

Auger intakes and harvesting machinery are a major cause of harm and injury. There have been two recent incidents in the agriculture industry involving young workers who suffered serious injuries after becoming entangled in unguarded augers. Young workers (aged up to 25) are considered a group of workers who are at increased risk in the workplace and require additional consideration when managing health and safety.

Grafton

28 July 2023

A 21-year-old worker was monitoring the flow of grain in an unguarded auger at a cattle farm when her hand became entangled in the auger. The worker suffered severe injuries to her right hand including a severed finger and significant damage to other fingers.

Walgett

6 August 2023

A 17-year-old worker was operating a grain mill at a feedlot when his foot became entangled and pulled into the moving auger. Emergency services attended site and cut the outer casing of the auger to free the worker’s foot. The worker suffered serious injuries to his foot.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with working near augers.

Ensure:

- parts of the auger that can cause injury are adequately guarded

- when access is not required during operation, maintenance or cleaning, the guarding is a permanent fixed barrier

- when access is required during operation, maintenance or cleaning, the guarding is an interlocked physical barrier that prevents access during operation of the plant

- if either of the above are not reasonably practicable, the guarding is a physical barrier that can only be removed using a tool, otherwise a presence-sensing safeguard system is used

- isolation and lock out/tag out systems are implemented when non-permanent guards are removed for maintenance and cleaning purposes and guards are replaced before the auger is restarted

- a suitable blockage clearing device is provided. Do not use hands or feet to clear blockages

- emergency stops are installed, clearly and durably marked, accessible and tested so they remain effective

- emergency plans are prepared, maintained and implemented

- adequate training and instruction is provided to all workers for the safe use of powered plant

- adequate supervision of young and inexperienced workers

- suitable communication systems are in place.

Related guidance material

- Managing the risks of plant in the workplace - Code of Practice (PDF, 1987.96 KB)

- Tools for employers to train and supervise young workers

- Safety first on farm a must to stem injuries

- Grain Safe fact sheet

- Equipment on farms

- How to use machine guarding - SafeWork NSW YouTube

- The A-Z of farm safety guide (PDF, 5673.78 KB)

Further information

- Traumatic event management plan – SafeWork NSW

- Mental health at work – NSW Government

- Speak Up Save Lives App – SafeWork NSW

- Subscribe to SafeWork NSW newsletters and updates

Tractor roll over fatality (19 April 2023)

A 40-year-old worker died when the tractor he was driving rolled shortly after crossing a cattle grid in Western NSW.

The road and cattle grid, where the incident occured.

Safety information

Farmers and farm workers are at risk of fatal or serious injury operating or working with tractors, implements and attachments.

Ensure:

Consider these ‘reasonably practicable’ control measures to manage the risks associated with tractors:

- before using a tractor with an attachment consider the risks to the operator, machine and environment in which it will operate

- attachments used on the tractor are:

- designed for the task being carried out

- installed and secured to the item of plant in accordance with manufacturer’s instructions

- suitable for the load being moved or lifted

- regularly inspected and maintained in accordance with the manufacturer’s instructions

- tractors between 560 and 15,000 kgs must be fitted with an approved Roll Over Protective Structure (ROPS)

- seat belts should be worn at all times when operating a tractor

- tractor operators are trained and competent in the correct use of the tractor and any attachments, and have access to all relevant safety information provided by the manufacturer.

Related guidance material

- Managing the risks of plant in the workplace - Code of Practice (PDF, 1987.96 KB)

- Virtual Farm Safety

- The A-Z of farm safety guide – SafeWork NSW (PDF, 5673.78 KB)

- Safety around your tractor (PDF, 1674.31 KB)

- General guide for managing the risks of machinery in rural workplaces - Safe Work Australia

- Farm Safety Advisory Program

Worker fatally crushed by olive harvester (26 May 2023)

A 67-year-old owner of an olive farm in Bumbaldry sustained fatal injuries when he was crushed between the hydraulic clamp of an olive harvester.

The olive harvester at the incident scene

Safety information

Many farm-related fatalities involve harvesting machinery. Consider ‘reasonably practicable’ control measures to manage the risks associated with the use of farm machinery.

Ensure:

- you establish and maintain agreed safe systems of work in relation to the use and operation of the machinery

- plant is properly immobilised, for example parked on a flat, level, hard surface, park brake engaged, ignition turned off and keys removed. Never attempt to access the plant or vehicle if it starts to roll

- bollards, barriers, safety rails and exclusion zones are in place to separate people from moving plant and vehicles

- the surrounding areas are inspected, and any potential risks such as over-head power lines and uneven ground are identified, and control measures are implemented to minimise the risk

- before operating the plant, look in all directions for people and be aware of the exclusion zones

- plant and machinery are inspected, tested and maintained in accordance with the manufacturer’s recommendations

- workers have the necessary training, experience, and supervision to identify hazards and control risks associated with carrying out maintenance on machinery

- adequate lighting is available to enable the task and any machine maintenance to be carried out safely.

Related guidance material

- Managing the risks of plant in the workplace – Safe Work Australia

- Guide for managing the risks of machinery in rural workplaces – Safe Work Australia

- How to manage work health and safety risks – Code of Practice (PDF, 556.72 KB)

- The A-Z of farm safety guide – SafeWork NSW (PDF, 5673.78 KB)

- Farm safety self-assessment (PDF, 478.11 KB)

11 metre fall from Elevating Work Platform (15 March 2023)

A 42-year old worker was undertaking embankment remediation work from a boom-type elevating work platform (EWP) when he was hit by a tree, causing him to be catapulted from the platform. The worker fell approximately 11 metres to the ground. The worker was wearing a fall arrest harness but the lanyard was not connected to the anchor point on the work platform.

EWP on embankment and a close-up of damage to the work platform

Safety information

In Australia, you need to be authorised by a high-risk work licence to carry out high-risk work. High-risk work includes operating specified machinery, including boom-type elevating work platforms (WP) where the boom length is 11 metres or more.

Consider ‘reasonably practicable’ control measures to manage the risks associated with working from heights including work from an elevated work platform.

Ensure:

- the right EWP is chosen for the job and only use it for the purpose it was designed

- the rated capacity of the EWP is not exceeded

- information, instruction, and training is provided to workers who use EWPs

- workers are trained in emergency procedures so occupants can be rescued in the event of an emergency

- workers hold a current high-risk work licence for boom type elevating work platforms where the boom length is of 11 metres or more

- a prestart (pre-operational) inspection is carried out and information in the logbook is verified

- operational checks are carried out to ensure the EWP is safe to use

- the ground conditions are suitable for ensuring the stability of the EWP, including operating on inclines

- hazards associated with working from an EWP are identified and risks are eliminated where reasonably practicable. To help you do this, complete a safe work method statement (SWMS) in consultation with others to ensure all hazards and risks are accounted for

- EWPs are not operated if wind speed rating exceeds the maximum limits (as shown on the compliance plate)

- a safety harness is worn at all times and the lanyard is attached to a designated anchor point on the EWP

- safe distances are maintained when working near overhead electric lines

- exclusion zones are set up to keep the EWP separated from pedestrians, other workers, and traffic including other mobile plant

- EWP is regularly inspected and maintained.

Related guidance material

- Managing the risks of falls at workplaces - Code of Practice (PDF, 2326.56 KB)

- Managing the risks of plant in the workplace – Code of Practice (PDF, 1987.96 KB)

- High risk work licenses – SafeWork NSW

- AS2550.10 Cranes, Hoists and Winches - Mobile elevating work platform – Safe use – Australian Standard

- AS1418.10 Crane, Hoists and Winches - Mobile elevating work platforms – Australian Standard

Worker fatally crushed by backhoe (29 December 2022)

A 28-year-old farm worker suffered fatal injuries when the backhoe he was operating slid approximately 2 metres into a culvert and landed on its side. The worker was ejected from the machine and pinned under the cabin structure.

Safety information

Many farm related fatalities involve tractors, agricultural equipment and earth moving machinery. Consider ‘reasonably practicable’ control measures to manage the risks associated with the use of farm machinery and isolated or remote work.

Ensure:

- there are systems in place to ensure the health and safety of workers performing remote or isolated work

- site conditions are assessed for potential hazards i.e., ground conditions and systems are in place to eliminate and/or manage the site-specific risks

- appropriate machinery is selected for the job task

- a work plan is developed and is followed by all workers. The work plan must detail the:

- tasks to be performed

- how the tasks are to be performed

- the location of the tasks.

- workers are trained and competent in the use of plant and machinery

- safety devices such as seatbelts are fitted to plant and utilised as part of the safe system of work

- an emergency response plan is in place

- plant and machinery are regularly inspected and maintained by a competent person

- plant is properly immobilised e.g., parked on a flat, level, hard surface, park brake engaged, ignition turned off and keys removed. Never attempt to access the plant or vehicle if it starts to roll

- plant is securely stored when not in use to prevent unauthorised access or use.

Related guidance material

- How to manage work health and safety risks – Code of Practice (PDF, 556.72 KB)

- Managing the work environment and facilities – Code of Practice (PDF, 422.29 KB)

- Managing the risks of plant in the workplace – Model Code of Practice

- Farming safety resources

- Farm safety self-assessment (PDF, 478.11 KB)

- Guide for managing the risks of machinery in rural workplaces

- The A-Z of farm safety guide (PDF, 5673.78 KB)

- Remote or isolated work – safety information

- Incident information release – Bogged farm machinery fatality

Worker struck by falling hay bale (26 September 2022)

A truck driver has sustained serious injuries when struck by a hay bale weighing approximately 570kg. The bale fell from a truck whilst being unloaded at a rural property in Aberfoyle.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with unloading heavy loads using mobile plant.

Ensure:

- plant and machinery are designed for the task, and regularly inspected, tested and maintained in accordance with the manufacturer’s recommendations

- a detailed traffic management plan including the establishment of a clearly defined exclusion zone and procedures is implemented and enforced

- workers have the necessary training, experience and supervision to identify hazards and control the risks associated with unloading heavy loads and the general operation of mobile plant

- hay bales are never stacked higher than the lifting capabilities of the handling equipment being used

- to never load more bales onto handling equipment, to a height higher than the equipment is designed to handle, nor heavier than the rated capacity of the machine

- care is taken not to dislodge other bales – when lifting bales off a stack and reversing away, ensure that the bales are well clear before moving – do not ‘drag’ the bale across the surface of the bale below, this can lead to stacks becoming unstable

- stacks are always safe and checked regularly for movement

- bales are never removed from the bottom of overlapping layers, leaving overhanging bales unsupported

- a safe means to access the stack is always used.

Always remember – falls from stacks may occur during destacking. This can be caused by trying to free jammed bales, picking up bales with broken strings, and falling from edges. When destacking, plan the work to avoid incidents like these

Related guidance material

- Working with hay bales – WorkSafe QLD

- Safety around your vehicle – Glove Box Guide – SafeWork NSW (PDF, 1466 KB)

- Traumatic event management plan – SafeWork NSW

Further information

Bogged farm machinery fatality (18 June 2022)

A 33-year-old farmer sustained fatal head injuries during the extraction of a bogged bulldozer at his neighbour’s farm in Regional NSW. He had been assisting his neighbour with the extraction when one of the two D-Shackles connecting the recovery strap failed and was propelled through the glass door of the bulldozer.

An example of bogged farm machinery.

Safety information

There have been multiple fatal incidents involving the extraction of bogged agricultural plant in NSW over the past 12 months. The incidents involved the failure and subsequent propulsion of recovery straps and/or equipment through the windscreen of the plant during the attempted extraction.

Farming accounts for one in every five worker deaths. Reduce the risk to workers and others involved in vehicle and farm equipment recovery by:

- assessing the work environment and conditions prior to commencing work

- avoid using vehicles and farm equipment if there is a likelihood of becoming bogged

- postpone the work until conditions improve

- creating an exclusion zone around the vehicle or piece of equipment during the recovery activity

- only the vehicle operator and those necessary in the recovery should be allowed inside the exclusion zone

- ensure an effective communication method is established between them (voice, radio, hand signals)

- ensuring anyone within the exclusion zone is standing at 90 degrees to the axis of the tow line

- do not stand at either end of the tow line as you are at higher risk of injury if the tow line breaks

- only using straps and attachments that are correctly rated for the weight and type of work involved

- using a recovery damper to reduce the force of the recoil and risk of injury if the recovery line does break

- only using anchor points on vehicles and machinery approved by the manufacturer

- aborting the extraction of the bogged vehicle or equipment if things are not going to plan

- choosing plant with laminated glass and external structural protection where available

- consult the original equipment manufacturers (OEMs) for tougher glass options and operator cabin protection in mobile plant

- only using well maintained and approved equipment in line with the manufacturer’s instructions

- performing a risk assessment before attempting any vehicle or equipment recovery

- ensuring you have an emergency procedure in place.

Related guidance material

- Managing the risks of plant in the workplace – Code of Practice (PDF, 1987.96 KB)

- Safety around your vehicle (SAYV) glove box guide

- WHS duties in the agricultural industry – Safe Work Australia

Further information

Worker pinned under front-end-loader (8 June 2022)

A 45-year-old worker sustained serious injuries whilst undertaking engine repairs underneath a front-end-loader at a property located in Euabalong. The hydraulic jacks beneath the loader gave way, pinning the worker at the pelvis and hips.

Safety information

Incidents involving farm vehicles are a major cause of injury and death in the agriculture industry. Vehicle related incidents involve rollovers, vehicles running over people and incidents caused by unsafe maintenance activities.

Implement ‘reasonably practicable’ control measures to manage the risks related to working around farm vehicles.

Ensure:

- if plant is not in use, it should be stored so it does not create a risk to workers or other people in the workplace

- plant and machinery are inspected, tested and maintained in accordance with the manufacturer’s recommendations

- any inspection, maintenance or testing is carried out by a competent person

- control measures are implemented to eliminate, or if that is not reasonably practicable, minimise the:

- risk to health and safety of people during storage. For example, release stored energy, lower moving parts that fall under gravity and provide support to prevent toppling

- risks of damage to plant during storage. For example, risks may arise from corrosion because of exposure to residues of hazardous substances and deteriorating consumables

- the surrounding areas are inspected, and any potential risks are identified, and control measures are implemented to minimise the risk

- the worker does not place themselves in a position where they are at risk of serious injury

- workers have the necessary training, experience, and supervision to identify hazards and control risks associated with carrying out maintenance on heavy machinery.

Related guidance material

- Managing the risks of plant in the workplace – Safe Work Australia

- Guide for managing the risks of machinery in rural workplaces – Safe Work Australia

- The A-Z of farm safety guide (PDF, 5673.78 KB) – SafeWork NSW

- Refer to the Operators Manual provided by the plant manufacturer.

Further information

- Traumatic event management plan – SafeWork NSW

- Mental health at work – NSW Government

- Speak Up Save Lives App – SafeWork NSW

- Subscribe to SafeWork NSW newsletters and updates

Farmhand injured by front-end loader (13 February 2022)

A 22-year-old farmhand was preparing animal feed in the bucket of a front-end loader when the loader moved forward crushing the farmhand between it and the pallets of packaged mineral supplement.

Safety information

Machinery accounts for a high proportion of farm injuries or fatalities with tractor accidents being highly represented in farm injury and fatality statistics.

Implement ‘reasonably practicable’ control measures to manage the risks related to working with and around farm machinery.

Make sure:

- plant and machinery are inspected, tested, and maintained in accordance with the manufacturer’s recommendations

- any inspection, maintenance or testing is completed by a competent person, and recorded for future reference

- workers have the necessary training, experience and supervision to identify hazards, and control the risks associated with the uncontrolled movement and general operation of mobile plant.

Before operating mobile plant, you:

- must be trained and deemed competent to operate the mobile plant – make sure you understand the operating controls, and the manufacturer’s instructions on safe operation and maintenance

- should always conduct pre-start and operational safety checks to confirm the mobile plant is safe to operate, including testing braking systems.

Related information

- Managing the risks of plant in the workplace – SafeWork NSW Code of Practice

- Managing the risks of machinery in rural workplaces – SafeWork Australia

- The A-Z of farm safety – SafeWork NSW

- Farm machinery fact sheet – SafeWork NSW

- Refer to the Operators Manual – provided by the plant manufacturer

Download this Incident Information Release as a PDF (PDF, 506.06 KB)

Quad bike fatality (14 January 2022)

A 19-year-old farm worker sustained fatal injuries in a quad bike roll over incident. The incident occurred while maneuvering through a grassed creek. The worker had been tasked with spraying thistles from the quad bike.

Safety Information

Quad bikes continue to be the biggest killer on Australian farms, with roll over the most common cause of death. Over 80% of quad bike fatalities in NSW are due to quad bike roll over.

Farm owners and operators must be aware that quad bikes are high risk vehicles and are not safe for use on all terrains or for all tasks.

As a farm owner or farm operator you are responsible for anyone operating a quad bike at your workplace. You must identify the risks associated with quad bike use and do what you are reasonably able to do to eliminate those risks.

Before using a quad bike at your workplace:

- choose the safest vehicle for the job - ensure a quad bike is appropriate for the task, terrain, and the rider

- install an operator protection device (OPD), also known as a roll bar to your quad bike

- tell someone where you are going and when you plan to return – carry a communication device

- check weights and positioning of items being transported

- stabilise loads and consider using internal baffles in tanks to reduce the movement of liquid

- check the tyre pressure before use and at regular intervals

- use and maintain the quad bike in accordance with the manufacturer’s instructions

- assess the environmental conditions and be aware of long grass, rocks, trees, fallen branches, creeks, and gullies, and where the ground is soft or affected by weather or other conditions

- ensure the rider is trained and capable to safely operate and maintain the quad bike

- ensure no children under 16 ride on adult sized quad bikes – even as a passenger.

When using a quad bike at your workplace:

- wear a compliant helmet and other personal protective equipment such as goggles and sturdy footwear

- ride at a speed suitable for the conditions

- avoid traversing on steep, uneven, or slippery terrain.

More information

- Quad Bike Safety - SafeWork NSW

- Quad Bike Side by Side Vehicles – SafeWork NSW

- Quad Bike Safety Rebate Program – SafeWork NSW

- Quad Bike and Side by Side Vehicle Training Program – SafeWork NSW

- Quad Bike Workplace Safety Survey Study - UNSW

Fall from silo (28 October 2021)

A grain farmer received serious injuries when he fell approximately 10 metres from the top of a silo. New silos had been installed at the property and a witness report indicates that the farmer was releasing the lid on the first silo when he attempted to jump to the second silo and fell.

Top of silo and access lid

Access ladder of top of silo

Safety information

Incidents of falls when moving between two silos can be prevented by providing safe elevated access between the silos, such as a fixed walkway with suitable guardrails or enclosure. Alternately, the silos could be positioned far enough apart that jumping between them is not possible.

Never jump from one silo to another

This is a timely reminder that work on or around silos is dangerous. For more information on general silo safety please visit the SafeWork NSW Silo Safety webpage.

Statistics

Falls from silos, windmills, buildings and machinery during maintenance and harvest are among the main causes of death and injury on farms. 30 people have died on Australian farms in the last decade falling from heights. Don’t take chances, always be safe working at heights.

More information

- Managing the risks of falls at workplaces – Code of Practice

- Silo safety – Falls from heights video – SafeWork NSW

- Silo safety self-assessment checklist - SafeWork NSW

Worker struck by forklift (16 August 2021)

A 19-year-old worker was struck by a forklift while assisting to collect chickens within a poultry shed. The forklift was moving forward carrying a module of cages in front of the cabin when it struck the worker. The worker sustained fatal injuries as a result of the incident.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with operating forklifts.

Businesses:

- separate people from moving forklifts, using barriers or guardrails

- if you cannot physically separate forklifts from people, designate exclusion zones

- if your forklifts do not have safety features, consider retro-fitting warning devices like forklift-to-worker proximity sensors, reverse lights, reverse sensors, flashing lights, beepers, quackers and focus beams

- ensure all workers operating a forklift have the appropriate high risk work licence and have received training on the type of forklift they are using

- if lighting levels in the work environment are poor, consider fitting additional lighting to the forklift

- talk to all workers - including operators and those who work near forklifts - about how to work safely around forklifts

- ensure workers are wearing high visibility clothing and using other appropriate personal protective equipment.

Forklift operators:

- before moving your forklift, look in all directions for people

- be aware of exclusion zones and pedestrian walkways

- ask about fitting safety or proximity warning devices to your forklift

- always look in the direction of travel and keep your forks lowered

- if the load obscures your view, drive in reverse

- if your vision is restricted, or if travelling in reverse is not practical, use a trained spotter and ensure that you cease operation if the spotter disappears from view

- do not use headphones or operate electronic devices such as mobile phones while operating the forklift.

When working near forklifts:

- always keep a safe distance

- do not work between the path of the forklift and a fixed object even if the park brake is applied

- stay on pedestrian pathways and/or exclusion zones

- be aware that a forklift operators’ field of vision is obscured – don’t assume they have seen you

- wear a forklift-to-worker proximity warning device, if available

- wear high visibility clothing and other appropriate personal protective equipment.

Statistics

Every year forklifts cause workplace deaths and injuries resulting in substantial financial and human costs for workers, industry and the community. The three main reasons workers are killed or seriously injured in forklift incidents are:

- being hit or crushed by a forklift

- being hit or crushed by a load that the forklift is moving

- being crushed in a forklift tip-over.

More information

- Code of practice – Managing the risks of plant in the workplace (PDF 1.5MB)

- Industrial lift trucks guidance material - Safe Work Australia

- Workplace traffic management guidance material - Safe Work Australia

- Forklift safety information – SafeWork NSW

The following incident occurred in October 2020 at a poultry farm:

Fatal telehandler incident (13 October 2020)

A farm worker died after he was run over by a 3-tonne telehandler as it was reversing. The telehandler operator was transporting straw bales from a stack into a straw chopper located near a poultry shed. As the operator reversed to pick up another bale from the stack, the worker was run over by the telehandler.

The telehandler including its location

Safety information

Site specific traffic management control measures must be implemented to manage the risk of mobile plant causing harm to pedestrians.

Keep people and vehicles apart. Have clearly defined pedestrian only spaces and vehicle only spaces, by:

- implementing fixed and secured barriers that prevent people accessing vehicle only areas,

- defining pedestrian areas through permanent or temporary barriers or markings, or

- use high impact traffic control barriers e.g. bollards or temporary structures.

If it is not reasonably practicable to separate people and vehicles, implement additional controls to minimise the risks such as:

- using devices like reversing sensors, reversing cameras, mirrors, rotating lights or audible reversing alarms

- have a spotter direct the reversing vehicle (the spotter must remain in visible contact with the driver at all times)

- provide clearly identified designated reversing areas

- restrict the use of mobile phones by drivers and pedestrians.

Develop a traffic management plan for the site which covers controls and procedures. Further to that, train, instruct and supervise your workers on the traffic management plan.

More information

Code of practice – Managing the risk of plant in the workplace (PDF 2.1MB)

Workplace traffic management guidance material - Safe Work Australia

Plant: Your health and safety guide (PDF 520kb) – WorkSafe Victoria

Paying attention to whether or not your everyday tasks are done safely could be the very thing that prevents an injury to yourself or your workmates.

This short video will help you do a quick refresh of your basic safety practices when working in a goods yard, freight terminal or any workplace that requires you to be around trucks or forklifts.

Video: view time: 2 minutes 17 seconds.

Being hit by a moving object is one of the leading causes of fatalities in the manufacturing industry. Listen to SafeWork NSW Inspector Brian Hughes share his stories and his top tips for staying safe.

Video: view time: 2 minutes 27 seconds.

Tractor attachment fatality (3 October 2020)

A 52-year-old worker was killed while conducting minor maintenance works on a home-made front tank attachment on a tractor. Initial inquiries indicate the worker was crushed when the attachment, suspended by the tractor, shifted, resulting in a partial failure of the welded area.

Safety information

You must consider ‘reasonably practicable’ control measures to manage the risks associated with working with tractors and attachments, including:

- assessing the risks associated with each attachment used on the tractor

- planning and selecting the correct equipment or attachment for the task

- ensuring any attachments used on the tractor are:

- designed for the task being carried out

- installed in accordance with the supplier or manufacturer’s instructions

- suitable for the load being moved or lifted

- regularly inspected and maintained in accordance with the manufacturer’s instructions

- establishing safe systems of work for inspecting or working underneath a tractor including lowering any moveable attachments to the ground or blocking the attachment

- ensuring any work or modification to the tractor is designed and carried out by a competent person

- ensuring tractor operators and those making modifications are trained and competent in the correct use of the tractor and any attachments, and have access to all relevant safety information provided by the manufacturer.

More information

- Safe design and operation of tractors – Code of practice [PDF 512 kb]

- Managing the risks of plant in the workplace - Code of practice [PDF 2.1MB]

- Tractor safety precautions

- Safe use of tractors with attachments [PDF 5.5MB]

- Guide for managing the risks of machinery in rural workplaces

- ISO 6746-2 Earth-moving machinery – Definitions of dimensions and codes – Part 2: Equipment and attachments

Mobile plant rollover – serious incident (27 April 2020)

A worker sustained serious injuries while operating a roller-compactor at a rural property in the Hunter Valley when the vehicle rolled over. The roller-compactor was fitted with a rollover protection system, however the worker was not wearing a seatbelt and was ejected from the cabin through the front windscreen.

Safety information

Vehicle rollovers are one of the highest causes of fatalities in the agricultural industry. Businesses must implement ‘reasonably practicable’ control measures to manage the risks associated with the rollover of vehicles such as tractors and earthmoving machinery.

- Fit mobile plant with operator protective devices in accordance with the Work Health and Safety Regulation 2017. Operator protective devices include; a Rollover Protective Structure (ROPS), a Falling Object Protective Structure (FOPS), operator restraining devices and seatbelts

- Ensure mobile plant operators always wear a seatbelt while operating the machinery, to keep the operator within the protected ROPS/FOPS

- Consider the installation of warning devices and ignition interlocks for seatbelts in mobile plant

- Regularly inspect the ROPS/FOPS for rust, cracks, fatigue and deformation and replace any equipment showing any indication of reduced structural integrity

- Never modify the structure of the ROPS/FOPS (e.g. weld or drill) because it could undermine its structural integrity.

More information

Asphyxiation in farm tank (28 May 2020)

A worker suffered fatal injuries and a second worker attempting a rescue was rendered unconscious as a result of lack of oxygen, when conducting cleaning operations inside the confined space of a molasses tank at a rural property.

Site of incident incident molasses tank with (390mm) access hole

Safety information

Farm work may involve accessing confined spaces including various types of tanks, silos, and pits. Common hazards associated with working in tanks are:

- organic materials that ferment and result in oxygen depletion such as molasses

- using petrol or diesel motors inside tanks that generate toxic carbon monoxide

Warning! If someone collapses when working inside a tank, it is important to assess the risks before attempting to rescue them. A high number of people who die in confined spaces are the rescuers. If an incident occurs get help. Do not attempt a rescue without knowing the hazards, understanding the required response and using the proper safety equipment.

When working in or around a confined space such as a molasses tank always:

- consider if the work can be done another way without entering the confined space. For example, use external tank connections for cleaning or emptying the tank

- have a competent person conduct and document a risk assessment that considers the hazards, how the work can be done safely and the emergency response procedure

- test the atmosphere to identify if there is an oxygen deficient atmosphere or atmospheric contaminants and any flammable gas or vapour present in the space

- make sure only workers with a permit enter the space and a stand-by worker is supervising the work from outside the space

- put signs on or near any confined space and at each entry point to warn that only people who have been properly trained and have an entry permit can enter

- make sure there is a safe means of entry and exit

- establish emergency procedures and run regular practice drills with workers

- provide workers and supervisors with suitable and adequate information, training and instruction to do their work safely and without risks to health. This may include training in hazard identification and risk control methods, entry permit procedures, emergency procedures and how to use respiratory protective equipment

- keep records of training, risk assessments and confined space entry permits

More information

- https://www.safework.nsw.gov.au/hazards-a-z/confined-spaces

- SafeWork NSW confined space analysis and emergency plans

- Code of Practice: Confined Spaces August 2019

- https://www.safework.nsw.gov.au/your-industry/agriculture,-forestry-and-fishing/farming/silo-safety

- https://www.safework.nsw.gov.au/your-industry/agriculture,-forestry-and-fishing/farming/virtual-farm-safety-day

View the latest incident information releases at safework.nsw.gov.au

Recent spate of quad bike incidents (April 2020)

Date of incidents: April 2020

During April there were four separate serious incidents involving quad bikes and a side by side vehicle. Three of the incidents resulted in a fatality, the fourth resulted in spinal injuries to the worker. It is believed that all four incidents involved the vehicle rolling and crushing the rider.

Tamworth

On the morning of the 3 April 2020, a 64-year-old farm worker went to check stock on a sheep stud. When he didn’t return later that afternoon, a search party was organised involving Police and volunteers. The farmer’s body was found that night in a large sloping rocky outcrop, underneath an upright quad bike.

Wauchope

On 8 April, a man was moving his neighbour’s cattle on a side-by-side vehicle. When going up a steep incline the vehicle tipped and rolled, fatally crushing the man underneath. It appears the vehicle's seat belt was fastened so that the vehicle could be started, but not placed around the rider. The man was allegedly not wearing a helmet.

Gloucester

On 13 April, a 69-year-old man sustained a cracked vertebrae and ligament damage when his quad bike rolled over. Westpac Rescue Helicopter transported the man to hospital for treatment.

Grenfell

On 17 April, a 67-year-old woman was found dead in a paddock on her farm. Despite the flat terrain, it appears the quad bike she was riding rolled and crushed her.

Side-by-side vehicle involved in incident (left) and site of incident near Wauchope

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with quad bikes and side-by side-vehicles.

Make sure:

- the vehicle is appropriate for the task, the terrain and the rider

- you do a quad bike or side-by-side vehicle riding course

- you ride at a speed that’s suitable for the conditions

- you wear a seatbelt when operating side by side vehicles

- you wear an approved helmet

- you wear personal protective equipment, such as goggles and sturdy footwear

- you use and maintain the vehicle in accordance with manufacturer’s instructions

- you don’t overload the vehicle or tow anything that exceeds the vehicle's limits

- you assess the environmental conditions, and know where there are rocks, trees, creeks and gullies, and where the ground is soft and rain-affected – a drone might help

- you avoid steep terrain

- an operator protection device (OPD) is fitted to your quad bike

- someone knows where you're going – carry a mobile phone or other communication device

- no child under 16 years ride adult size bikes

- no passengers on quad bikes

Businesses are reminded of their duty to identify hazards and manage risks to health and safety in accordance with the provisions of the Work Health and Safety Act 2011 and Work Health and Safety Regulation 2017.

Statistics

- Since 2001, there have been more than 240 quad bike related deaths on Australian farms.

- Over 60 per cent of quad bike fatalities are due to rollover.

- About 30 per cent of quad bike fatalities involve head injuries.

- About 40 per cent of serious injuries from quad bike incidents involve a traumatic head injury.

- Wearing a helmet reduces the risk of fatality in a quad bike incident by 40 per cent.

More information

Leg caught in auger (20 April 2020)

A 22-year-old worker had his leg amputated after it became entangled in an unguarded in-ground auger, while he was cleaning grain out of a flat bottom silo.

Auger guard was removed

Safety information

Farmers and workers are killed or seriously injured every year while working on or inside silos.

The three key reasons are:

- falling from a height

- being overcome by fumes in a confined space

- getting dragged into the auger.

Consider ‘reasonably practicable’ control measures to manage the risks associated with working near augers and silos.

Make sure:

- parts of the auger that may cause injury – chutes, channels, belts, pulleys – are guarded

- guards can only be removed using a tool

- you use hydraulic rather than mechanical drive systems

- a competent person regularly inspects, maintains and services the auger

- you shut-off machinery before servicing

- you use a lock-out/tag-out procedure when working with augers – don’t use hands or feet to clear blockages

- guards are replaced after maintenance

- workers are trained to use augers

- inexperienced workers are supervised.

More information

Horse-handling head injury (26 March 2020)

Date of incident: 20 March 2020

A 20-year-old stablehand suffered a brain injury after she was kicked in the head and face by a horse, while leading it from its stable to a yard in windy conditions. Displaying flighty, anxious behaviour, it broke free of the lead rope and kicked out with both hind legs.

Safety information

Many workers have been killed or injured falling from a horse, or being bitten, struck or kicked.

When working with or around horses:

- match the person and the horse – knowledge of the horse’s background and the person’s skill level is vital – this involves a separate assessment of the person and the horse

- make sure all workers are inducted, trained and supervised

- make sure workers wear personal protective equipment, such as a helmet (compliant with AS/NZ 3836:2006 Helmets for horse riding and horse related activities or equivalent), safety vest, enclosed boots and gloves

- create a safe environment, with enough space for horses and workers, and suitable exit points

- develop safe work procedures for moving and handling horses

- move quietly and confidently around horses

- be alert to sudden changes in a horse’s behaviour

- consider the age and behaviour of a horse

- consider things that might ‘spook’ a horse, such as weather, traffic or other horses

- always be in a position where you can quickly move away from a horse

- never approach a horse in its kicking zone.

When leading a horse, you should:

- approach it with safety zones in mind, and make a noise so it’s aware you’re approaching

- do so from the left shoulder of the horse, with both hands on the lead rope

- do one horse a time.

Statistics

- More than 10 people are hospitalised every day due to a horse-related injury.

- More than 130 horse-related fatalities occurred in NSW between 2000 and 2014

- Young females are most prone to horse-related injuries, while males are most likely to suffer fatal injuries.

- 40 per cent of all injuries involve being hit by a horse.

More information

Farmer crushed by tractor (19 December 2019)

Date of incident: 19 December 2019

A farmer died after being crushed by a tractor when trying to jump-start it at a property in Coolabah

Incident scene

The investigation

- SafeWork NSW inspectors responded to the incident.

- SafeWork NSW commenced an investigation to determine the cause and circumstances of the incident.

Safety information

Businesses are reminded of their duty to identify hazards and manage risks to health and safety in accordance with the provisions of the Work Health and Safety Act 2011 and Work Health and Safety Regulation 2017.

Consider ‘reasonably practicable’ control measures to manage the risks associated with working on tractors. Make sure:

- the tractor is routinely inspected and maintained according to the manufacturer’s recommendations or, if none, the recommendations of a competent person

- all work on the tractor is done by trained and suitably experienced workers, according to the manufacturer’s recommendations

- interlocking devices that prohibit jump-starting are in proper working condition, and not bypassed or removed

- you don’t jump-start the tractor unless the manufacturer has given you specific procedures.

Further information

Tractor rollover (5 November 2019)

Date of incident: 5 November 2019

A 36-year-old man died when the tractor he was steering – which was being towed by another tractor – rolled over and crushed him. The incident occurred at Clybucca.

The investigation

- SafeWork NSW inspectors responded to the incident.

- SafeWork NSW commenced an investigation to determine the cause and circumstances of the incident.

Safety information

A vehicle rollover is one of the most common causes of fatalities in the agricultural industry.

Consider ‘reasonably practicable’ control measures to manage the risks associated with the rollover of vehicles such as tractors. Make sure:

- you don’t hitch above the centre line of the axle when pulling heavy loads

- you hitch to the front drawbar and use reverse gear when towing a vehicle, to eliminate the potential for the tractor to backflip

- you use the clutch gently when starting up a slope, or towing

- you use an approved fold-down ROPS, with a locking device, when working inside or close to buildings or trees – and install other rollover-protection measures when the ROPS is folded down

- you don’t steer sideways when going up or down a slope

- the tractor is fitted with a rollover protection structure (ROPS), in accordance with section 26 of the regulation – more information is in AS1636:1996

- the ROPS is regularly checked for rust, cracks, fatigue and deformation – if it is present, repair or replace the ROPS

- you don’t change the ROPS – weld it or drill it - without first getting advice from the manufacturer or a suitably competent person

- a seatbelt, when fitted, is always worn.

Further information

- Code of practice: Safe design and operation of tractors

- Tractor rollover protection structures (ROPS) – Requirements – WorkSafe Victoria

- Tractor safety precautions – WorkCover Queensland

- Safe use of tractors with attachments – WorkSafe WA

- Code of practice: Managing the risks of plant in the workplace

- Small business safety rebate program (includes purchase of a ROPS).

Side-by-side vehicle fatality (20 October 2019)

Date of incident: 20 October 2019

Incident overview

A male farmer sustained fatal crush injuries when the side-by-side vehicle (SSV) he was operating rolled on a farm in Kybeyan.

The investigation

Caption: Side-by-side vehicle involved in the incident.

- SafeWork NSW inspectors responded to the incident.

- SafeWork NSW commenced an investigation to determine the cause and circumstances of the incident.

Safety information

Businesses are reminded of their duty to identify hazards and manage risks to health and safety in accordance with the provisions of the Work Health and Safety Act 2011 and Work Health and Safety Regulation 2017.

Businesses must implement ‘reasonably practicable’ control measures to manage the risks associated with operating a side-by-side vehicle, including

- doing a side-by-side vehicle driving course

- driving at a speed that’s suitable for the conditions

- wearing a seatbelt and helmet

- maintaining the vehicle in accordance with manufacturer’s instructions.

Further information

You can also refer to the following guidance materials:

Farm vehicle fatality (5 October 2019)

Date of incident: 5 October 2019

A 38-year-old man sustained fatal injuries after losing control and rolling a 4WD farm vehicle as he descended a steep hill at Yaven Creek, near Adelong, in the Riverina region of NSW.

The investigation

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks of using plant, such as farm vehicles, on steep terrain. Make sure:

- the vehicle is appropriate for the task and the terrain

- the vehicle is maintained according to the manufacturer’s recommendations

- you reduce the tyre pressure, to increase the traction

- you use seat belts and drive in low gear

- the load is secure and doesn’t affect the vehicle’s stability

- you assess the environmental conditions, knowing where there are rocks, trees, creeks and gullies, and where the ground is soft and rain-affected – consider walking the route before driving

- you have plan B if the terrain is too steep or the vehicle too unstable

- the driver is well-trained in using the vehicle for the task being undertaken.

Further information

Cattle crush fatality (6 August 2019)

Date of incident: 6 August 2019

Incident overview

A 69 year old, male, contract transport driver sustained fatal crush injuries after being struck by a bull in north western NSW. The worker was loading cattle onto a single deck trailer cattle transporter when a bull turned to exit the truck and pinned him against the race wall.

The investigation

- SafeWork NSW inspectors responded to the incident.

- SafeWork NSW commenced an investigation to determine the cause and circumstances of the incident.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risk of being crushed, kicked, trampled or gored. If you work with cattle during loading or unloading you are at greater risk of being injured when:

- you are inside the confines of the loading ramp (either behind or in between the cattle)

- you put your limbs through the bars of the ramp to move the cattle up or down the ramp.

Handlers must anticipate unpredictable animal behaviour when animals are in confined situations during loading, particularly when loading cattle by ramp. To stay safe:

- Train workers to perform the task safely.

- Design the loading ramp to accommodate the size and flow of the cattle.

- Ensure the width of the loading ramp is appropriate to the breed or class of cattle that will be negotiating the ramp.

- Ensure the slope of the loading ramp is not too steep.

- Put sheeting or panels along the walls of the loading ramp (sheeted panels make the cattle focus on the ramp exit and eliminate other distractions, sheeting also prevents your legs getting caught).

- Use a non-slip material on the floors of the ramp that does not vibrate or create noises likely to startle the animals.

- Use a catwalk and handrail alongside the ramp to help handlers move cattle at a safe distance.

- Fix a sliding gate at the top of the ramp that can be safely used to secure animals on the truck once it is loaded.

- Employ ‘low stress’ livestock handling techniques during loading or unloading.

Further information

You can also refer to the following guidance materials:

- Guide to managing risks in cattle handling

- Working with livestock: factsheet

- Cattle handling safety – a practical guide

- Guide for safe design of livestock loading ramps and forcing yards

- Safe loading and unloading of cattle – WorkSafe QLD

- Small business safety rebate program (use towards purchase of a cattle crush)

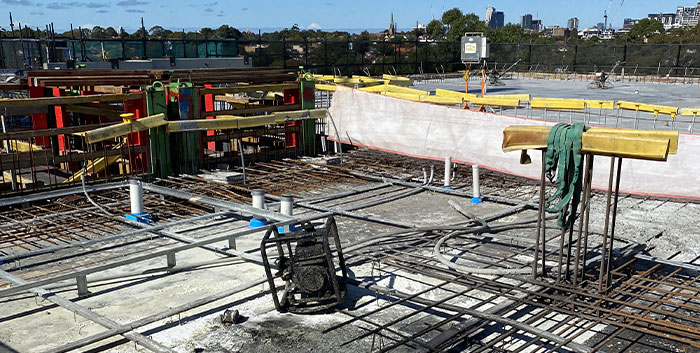

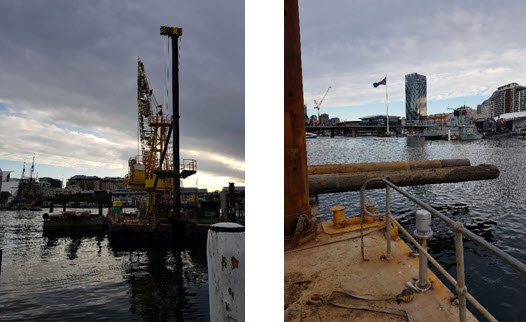

Construction

Plumber falls from roof while cleaning gutters (21 March 2025)

A plumber was standing on a roof and using a blower to clean gutters. He fell approximately 4.4 metres to the ground and sustained serious injuries.

Safety information

The biggest risks for roof work are falling off the edge or through fragile roof materials. Consider ‘reasonably practicable’ control measures to eliminate or manage the risks associated with falls from heights.

Ensure:

- the work is completed from ground level where possible, for example, by using a high reach blower or vacuum system

- a roof inspection is carried out before works begin. This should be done by a competent person who can assess the condition of the roof and identify any areas that should not be accessed due to poor condition, fragile roof materials or other risk factors

- you complete a risk assessment, and consult with workers to determine if the use of a fall prevention system is possible with safe access, such as:

- a secure fence, and

- edge protections, and

- working platforms, and

- covers.

- if it is not reasonably practicable to use a fall prevention device or a work positioning system, use an appropriately set up and connected fall arrest system, such as a harness-based fall-arrest used with lifelines or individual anchors

- all workers are adequately trained and competent in fall prevention and harness-based systems before their use

- if a ladder is used as an access, it must be adequately secured, and three points of contact must always be maintained

- you are aware of the structural adequacy, slope and slippery nature of the surface

- you are aware of weather conditions such as wind and rain

- a site-specific Safework Method Statement (SWMS) is developed and implemented for work where a person could fall more than two metres

- all workers have completed a site induction prior to commencing work

- emergency plans are prepared, maintained and implemented.

Related guidance material

- Code of Practice – Managing the risk of falls in the workplace (PDF, 2326.56 KB)

- AS/NZS 4994.2-2023 Temporary edge protection Part 2 Roof edge protection

- Safety Checklist - Working at heights in construction (PDF, 208.69 KB)

- Fact Sheet - Roof edge protection

- Pocket Guide – Construction Safety (PDF, 1352.71 KB)

Further information

Worker fatally injured adjusting bin tarpaulin cover (20 March 2025)

A skip truck driver was standing at the rear of his vehicle, using a remote control to adjust the position of a bin tarpaulin cover, when he was struck by another vehicle. He sustained fatal injuries.

Safety information

Consider ‘reasonably practicable’ control measures to manage the risks associated with moving plant interactions.

Identify hazards

Identify hazards by:

- consulting with workers and mobile plant operators

- identifying where mobile plant may interact with pedestrians or other vehicles

- determining potential locations and circumstances where people, plant and vehicles could collide – for example, when workers are required to alight from their vehicles.

Minimise risk

Eliminate the risk, if possible. If elimination isn’t possible, minimise the risk by:

- Designing the layout of the workplace so

- workers are not required to exit their vehicles

- interaction between pedestrians and mobile plant and other vehicles is minimised

- using physical barriers and/or exclusion zones to separate workers from mobile plant and vehicles

- ensuring there are clear, reliable communication systems in place

- ensuring all workers and other site users are aware of the traffic flow pattern, site rules, control measures and communication systems

- ensuring workers wear high visibility clothing

- ensuring designated driver safe zones and safe work zones are utilised on site to separate workers from mobile plant

- any area where the mobile plant and/or vehicles are required to reverse poses an additional risk and higher levels of controls should be implemented for example: scheduling work so that vehicles and pedestrians are not operating simultaneously in the one area

- developing, implementing and maintaining a traffic management plan

- separating designated areas for pedestrians and vehicles.

Control measures

At most sites, a combination of control measures will be required to effectively manage the risks associated with mobile plant. You should:

- maintain and review control measures. Control measures need to remain effective, particularly if the workplace is changing. Systems should be in place to:

- assess the effectiveness of current control measures

- allow reporting and feedback on the effectiveness of the control measures

- ensure workers are implementing control measures correctly

- identify upcoming changes to the workplace environment (layout, shared services etc) or work procedures (new equipment or processes, worker training etc) before they occur, and assess the potential impact on control measure,

- identify and assess possible alternate control measures (for example. new technology).