Roof edge protection fact sheet

This Fact Sheet provides guidance to business and workers who work on roofs, about how and when to use temporary edge protection systems.

Introduction

Falls from heights is the number one cause of death on NSW construction sites. The most serious and fatal falls are from roofs, ladders and scaffolds, and from a height of under 4 metres.

Where the need to work from a roof cannot be reasonably eliminated, the best control measure for preventing falls over a roof edge is physical guardrails. There are numerous proprietary temporary edge protection systems available, that can be used for a wide range of roof types.

Physical barriers such as temporary edge protection or covers must also be used where reasonably practicable to prevent falls through fragile roof surfaces such as skylights and polycarbonate sheeting.

Harness-based restraint or fall arrest systems should only be considered after a risk assessment has determined the use of temporary edge protection is not reasonably practicable.

Download this page as a PDF: Roof edge protection fact sheet (PDF 2.2MB)

Selecting a temporary edge protection system

When determining whether a particular temporary edge protection system is suitable for your site, you should make sure

- the system has been designed, manufactured and tested in accordance with AS/NZS 4994.1 Temporary edge Protection, Part 1: General Requirements

- the system can be installed and dismantled at the site and on your particular roof in accordance with AS/NZS 4994.1 Temporary edge Protection, Part 2: Roof Edge Protection – Installation and dismantling, and the manufacturer’s recommendations. The system designer/manufacturer/supplier must provide instructions for how to use the system correctly, including safe installation/dismantling, acceptable configurations, suitable roof types and system limitations.

- the site can accommodate the safe installation and dismantling of the system e.g. there is sufficient space for a mobile elevating work platform, taking into consideration any overhead or underground services and the site ground conditions.

- the system is compatible with the roof supporting structure and can maintain the system’s designed integrity / strength. Consult with competent persons where necessary.

- the system can be erected to follow the roof’s profile without gaps through which a person could fall. Buildings with unusual plan profiles or roof construction may pose additional hazards.

- safe personal access and exit from the roof can be achieved at the site without needing to step over or through the edge protection system.

Note: Scaffolds may also be used as temporary edge protection if they comply with AS/NZS 4994.2 Temporary edge Protection, Part 2: Roof edge protection- Installation and dismantling.

Prior to installation / dismantling

Prior to installing or dismantling your temporary edge protection, make sure:

- A method for installation and dismantling is developed by competent persons in consultation with all relevant parties. The method should prescribe the tasks and work sequence that ensures workers are protected from falls during installation and dismantling. The method should also prescribe any exclusions zones and provide a layout plan. Any method that requires work above 2m in height should be documented in a site specific Safe Work Method Statement.

- The location and voltage of overhead powerlines is confirmed to ensure safe distances can be maintained at all times or controls are in place as per the Code of Practice for work near overhead powerlines.

- The necessary instruction, training and supervision is provided to workers involved in the installation and dismantling of the system.

Installation / Dismantling

Only persons who have the required knowledge, skills, training and equipment regarding the system components, the manufacturer’s recommendations, and the developed method and sequence should install or dismantle the system. Any additional instruction, training, and supervision should be provided where necessary.

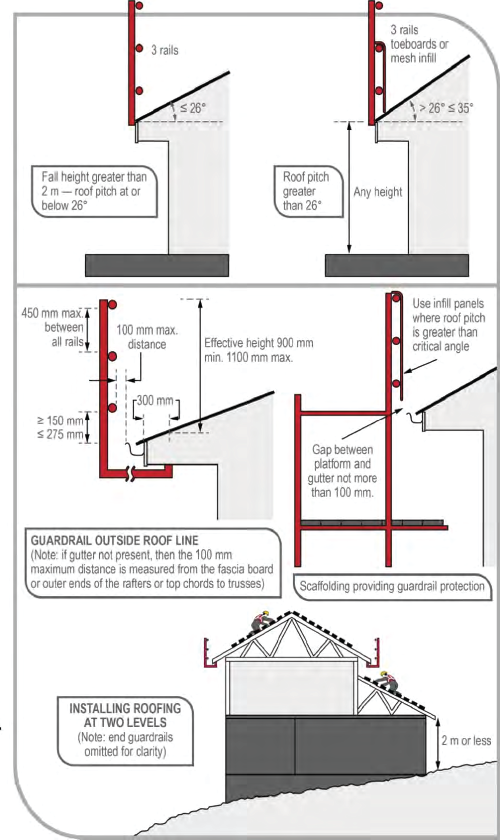

Temporary edge protection systems should include:

- Top, mid and bottom rails or toe-boards with gaps not exceeding 450 mm. Where toe-boards are used in place of bottom rails they should be able to withstand the likely impact loads.

- Toe boards or mesh infill to prevent tools, materials or debris falling from the roof, unless exclusion zones that prevent all personal access below the roof edge are in place.

- No gap between the roof edge, including the gutter, and a guardrail located outside the roof line exceeding 100 mm

- A clear distance between the roof cladding and the bottom rail of not less than 150 mm and not greater than 275 mm.

- A guardrail height above the roof surface of not less than 900 mm (for roofs with a pitch over 10 degrees the effective height should be measured from a point 300 mm inside the roof edge).

- Infill panels are used where the pitch of the roof exceeds 26 degrees.

After installation

Once installed, temporary edge protection systems should be inspected to ensure the installation complies with AS4994.1 and the designer/manufacturer/suppliers’ instructions.

Inspections should be undertaken:

- upon completion of the installation and prior to persons accessing the roof;

- periodically, e.g. monthly; and

- following unplanned events e.g. adverse weather.

Inspections should be recorded and include evidence of the condition of the temporary edge protection at the time of the inspection e.g. photographs.

Ensure a handover certificate is provided as per AS4994.2.

Further information

- Code of practice for managing the risk of falls at workplaces

- Code of practice for managing the risk of falls in housing construction

- SafeWork NSW Work near overhead powerlines – the basics

- Code of Practice work near overhead powerlines

- Construction falls from heights safety checklist

- Safe Work Method Statement template

- Housing industry site safety pack

Download this page as a PDF fact sheet

SafeWork NSW Roof edge protection fact sheet (PDF 2.2MB)

Catalogue no. SWNSW_32176_21