Hazardous chemicals

Exposure to chemicals is 100% preventable. Without the proper controls chemical exposure can cause cancer, respiratory illnesses, skin and eye irritations, as well as fire and explosion-related injuries.

Priority hazardous chemicals

Reducing exposure to hazardous chemicals at work is essential to creating a healthy, safe and productive workplace.

There are thousands of hazardous chemicals used in the workplace, from paints to pesticides, cleaners and fuels. They come in various forms – powders, solids, liquids and gases.

If you have a large amount of hazardous chemicals, go to hazardous chemicals notification page.

Select a hazardous chemical below to learn how to protect yourself.

-

Acrylamide

Acrylamide is a white odourless crystalline solid. It is soluble in water, ethanol, ether and chloroform.

-

Benzene

Benzene is a clear, colourless and flammable liquid that can originate from natural sources (crude oil) or be produced from chemical processes.

-

Carbon monoxide

Carbon monoxide is an odourless gas produced as a result of incomplete combustion processes.

-

Chromium VI

Chromium (VI) is a toxic form of the metallic element chromium, and is typically generated through industrial processes.

-

Crystalline silica (quartz)

Crystalline silica (quartz) is a natural mineral found in many products, such as sand, concrete and granite.

-

Dichloromethane

Dichloromethane, also called methylene chloride, is a volatile, colourless, non-flammable liquid with a sweet ether-like odour.

-

Formaldehyde

Formaldehyde is a colourless, irritating and unpleasant smelling flammable gas.

-

Isocyanates

Isocyanates are a group of highly reactive organic compounds that easily become volatile and enter the atmosphere as a vapour.

-

Methyl bromide

Methyl bromide (bromomethane) is a colourless, non-flammable gas with no taste or odour at low concentration.

-

Welding fumes

Welding processes can generate fumes which are tiny solid particles and gases.

-

Xylene

Xylene, also known as Dimethyl Benzene, is a colourless, sweet smelling liquid or gas that is widely used as a solvent.

Must do’s

There are specific laws about working safely with hazardous chemicals. Here we summarise those laws and give you some practical tips:

We also have information on exposure to chemicals in nail salons.

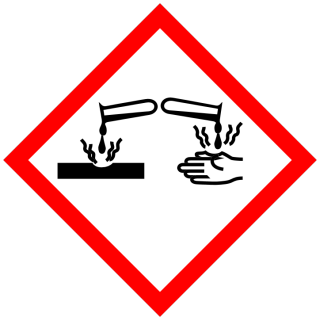

Globally harmonised system (GHS)

Key information on hazardous chemicals

-

Airborne contaminants

Airborne contaminants

Air should not contain chemical agents at concentrations that affect health, safety or well being. -

Chemicals and the GHS

Chemicals and the GHS

A new system of chemical classification and hazard communication came into effect in NSW in 2017. -

Explosives & fireworks

Explosives & fireworks

Our laws, licensing, and notifications system works together to regulate explosives, certain security sensitive dangerous substances and fireworks. -

Farm chemicals

Farm chemicals

Many pesticides used in the agricultural sector contain hazardous chemicals that can have short and long-term health effects if not managed safely. -

Flammable substances

Flammable substances

Flammable and combustible substances must be kept in the lowest practical quantity at the workplace. -

Glyphosates and organophosphates

Glyphosates and organophosphates

Chemicals containing glyphosate (commonly known as Roundup) and some other common pesticides have been assessed as being potentially carcinogenic to humans. -

Hazardous atmospheres

Hazardous atmospheres

Atmospheres affected by hazards such as insufficient oxygen, flammable gases and combustible dusts can pose an immediate threat to life or can interfere with the ability to escape unaided. -

Lead work

Lead work

Lead can harm your health and can be inhaled through dust, fumes or mist. It can also be swallowed. -

PFAS firefighting foams

PFAS firefighting foams

Information to current and ex-workers on the potential health concerns regarding the use, handling and storage of PFAS containing aqueous film forming foams (AFFF) and their contaminants.