Placarding for storage of hazardous chemicals

When emergency services respond to fires and chemical spills the responders need to know the potential hazards involved.

1. Introduction

When emergency services respond to fires and chemical spills at workplaces using, storing or handling hazardous chemicals, the responders need to know the potential hazards involved at such incidents. For effective and efficient emergency action, they need information about the type, quantity and locations of the hazardous chemicals stored at the workplace.

Placards are a means of alerting the emergency services and other persons to the presence of hazardous chemicals and providing information about them. They are an important part of an overall safety management strategy for workplaces using, storing or handling hazardous chemicals.

Workplaces using, storing or handling hazardous chemicals in tanks or in quantities exceeding prescribed quantities are required to be placarded under the Work Health and Safety Regulation 2017 (WHS Regulation). This guide provides information on how to identify when placarding is needed and the types of placards required.

Function of placards

Placards serve to:

- alert people (workers, contractors, visitors and emergency service personnel) to the presence of hazardous chemicals

- identify hazardous chemicals stored in bulk (eg tanks)

- identify areas where significant quantities of hazardous chemicals in packages are stored

- identify the hazards of goods present, and

- indicate the required emergency actions for hazardous chemicals in tanks through the use of the HAZCHEM code.

Application of placards

Placards are applicable to storages of those hazardous chemicals to which Part 7.1 of the WHS Regulation applies. Refer to Part 7.1 Division 1 for further details on the application of the hazardous chemicals provisions.

Essentially the placarding requirements under the WHS Regulation are the same as that required under the former Occupational Health and Safety Regulation 2001 (repealed on 31 December 2011) with some differences as described below:

- Globally Harmonised System (GHS)1 categories are now reflected in the placarding and manifest table (Schedule 11) replacing the references to the ADG Code dangerous goods classes, divisions, and packing groups

- prescribed placarding quantity for flammable gases (eg LP gas and acetylene in cylinders at a workplace) is reduced from 500L to 200L

- prescribed placarding quantity for industrial gases (eg compressed nitrogen, argon or oxygen in cylinders) is reduced to 1000L

- Class 9 dangerous goods are no longer included in Schedule 11 table for placarding.

It should be noted that while the WHS Regulation has introduced the GHS for classification and labelling of hazardous chemicals, the associated GHS pictograms are not referred to for placarding purposes. That is, GHS pictograms are not used for placarding of tanks and storage areas. Class labels from the ADG Code have been retained for the purposes of identifying hazardous chemical storages at workplaces. Appendix 1 shows the ADG Code class labels that will be applicable for the equivalent GHS hazard categories to which the WHS Regulation apply.

2. Definitions

ADG Code means the document known as the Australian Dangerous Goods Code comprising the Australian Code for the Transport of Dangerous Goods by Road and Rail, 7th Edition, available at ntc.gov.au.

Aerosol means a non-refillable metal aerosol dispenser, pressurised by liquefied, dissolved or compressed propellant gas.

Bulkmeans any quantity of a hazardous chemical that is:

- in a container with a capacity exceeding 500L or net mass of more than 500kg, or

- if the hazardous chemical is a solid; an undivided quantity exceeding 500kg.

Static tanks and transportable containers such as isotainers and intermediate bulk containers (IBCs) are examples of bulk containers (ie tanks) requiring a tank placard for hazardous chemicals at a workplace.

Class means the hazard class of the dangerous goods as stated in the ADG Code. A class may include divisions and packing groups (PG) where PG I – great danger, PG II – medium danger, and PG III – minor danger.

Goods too dangerous to be transported (GTDTBT) means goods listed in Appendix A of the ADG Code as goods too dangerous to be transported. These goods are inherently unstable but it may be possible to transport the goods after mixing them with diluents, stabilisers, inhibitors, desensitisers, phlegmatizers, solvents, wetting agents or adulterants to overcome the instability.

Hazardous chemical means a substance, mixture or article that satisfies the criteria for a hazard class in the GHS as defined in the WHS Regulation. Hazardous chemicals that are subject to the WHS Regulation covers dangerous goods excluding explosives (Class 1), radioactive materials (Class 7), infectious substances (Division 6.1) and certain miscellaneous dangerous goods (Class 9).

Packaged hazardous chemicals means Schedule 11 hazardous chemicals in a container with:

- a capacity not exceeding 500L or

- a net mass not exceeding 500kg.

The term refers to the complete product consisting of the goods and their packaging for transport. Examples of hazardous chemicals in packages are shown below.

Gas cylinders, steel drums, and various bottles and small containers are examples of packages.

Subsidiary risk of the dangerous goods means the Class or Division number of any important risks that have been identified by the classification system and are shown in Table 3.2.3 Column 4 of the ADG Code and the product Safety Data Sheet (SDS).

3. Placarding requirements

The provision of placards is addressed in clauses 349 and 350 and Schedules 11 and 13 of the WHS Regulation. Placards are required to be made of durable and weather-resistant material and be maintained in good repair and legible condition.

3.1 Types of placards

The types of placards under the WHS Regulation include:

- outer warning placard for the entrance to the workplace

- information placards for hazardous chemicals in bulk (ie tanks and stockpiles)

- information placards for hazardous chemicals in packages.

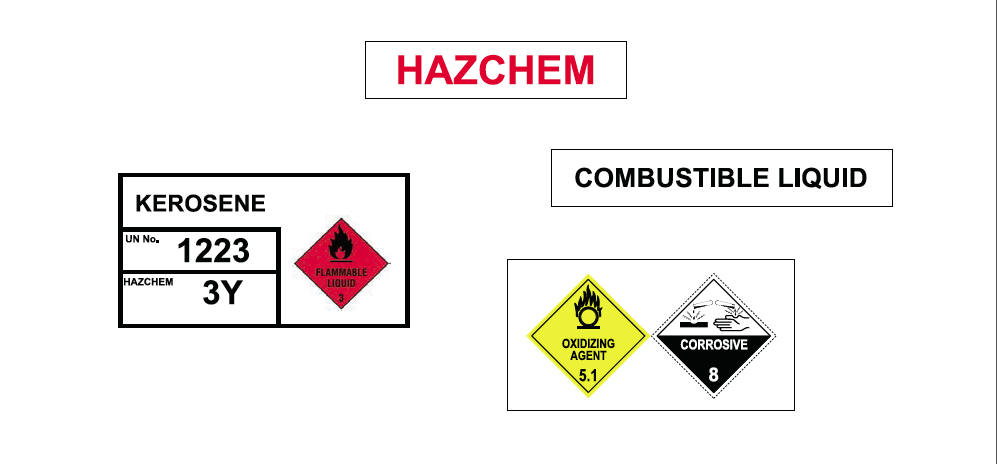

3.1.1 Outer warning placards

An outer warning placard, or HAZCHEM sign, is required at the entrance to the workplace when the workplace exceeds a prescribed placarding quantity in the Schedule 11 table. It must conform to the design in Schedule 13 of the WHS Regulation as shown in Figure 1. The word HAZCHEM must be in red lettering, not less than 100mm high, on a white or silver background.

Figure 1: Form and minimum dimensions of an outer warning placard

Note that this requirement no longer applies to fuel retailers (ie service stations). An exemption is provided in clause 349 (3) of the WHS Regulation.

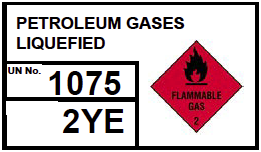

3.1.2 Information placards for hazardous chemicals in bulk

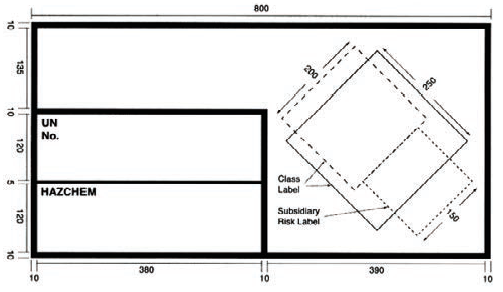

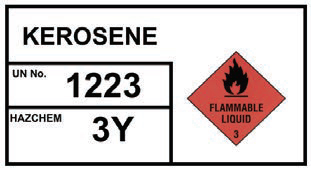

Bulk containers such as tanks used to contain hazardous chemicals are required to have specific information placards that have the form and dimensions shown in Figure 2.

Figure 2: Form and dimensions for a hazardous chemicals tank placard

The placard must contain the following information about the goods stored in the tank:

- the proper shipping name

- UN number

- HAZCHEM code

- ADG Code Class label

- subsidiary risk label (if applicable). For more than one subsidiary risk, the width of the area on the right hand side for the subsidiary risk label may be extended.

This information is available from the product's SDS and the ADG code.

Information on the placard must meet the following specifications:

- text must be black on white background (or white on a black background for the HAZCHEM Code)

- lettering must be at least 100mm high, unless two lines are used (50mm lettering)

- the Class and subsidiary risk label must be in the form and colouring of the ADG Code

- the Class label must have sides of 250 mm in length

- where there is a subsidiary risk, the Class label may have sides 200mm in length

- subsidiary risk labels must have sides of not less than 150mm.

Information placards for tanks containing hazardous chemicals are similar to the full-size Emergency Information Placards (EIP) required by the ADG Code for bulk transport, with the emergency contact detail removed. Tanks must be placarded at all times unless they are confirmed to be free of hazardous chemicals.

Combustible liquids in tanks

Category 4 flammable liquids are equivalent to C1 combustible liquids having a flash point greater than 60°C and ≤93°C. An example of a hazardous chemical in this category is diesel fuel.

The information placard for a tank of Category 4 flammable liquid must have the words COMBUSTIBLE LIQUID in lettering not less than 100mm high in black on a white or silver background. Figure 3 below illustrates the form and dimension required.

Figure 3: Placard for category 4 flammable liquids

Goods too dangerous to be transported (GTDTBT) in tanks

Information placards for GTDTBT in tanks must be in the form and dimensions as shown previously in Figure 2 with the following adjustments:

- the name of the goods given in Appendix A of the ADG code must be shown in the top left hand area

- the field reserved for the UN number must be left blank

- the field reserved for the HAZCHEM code must be left blank and

- the label displaying the words 'Unstable goods' and 'Too dangerous to transport' shown in Figure 4 must be shown in the field normally reserved for the class label.

Figure 4: Form of label for GTDTBT

How to calculate quantity of hazardous chemicals in tanks

- For solids, the quantity is to be calculated by the mass in kilograms that the tank is designed to hold.

- For liquids, the quantity is to be calculated by the design capacity of the tank in litres.

- For gases, the quantity is to be calculated by the total water capacity in litres of the tank.

How to calculate quantity of solid hazardous chemicals not in a tank or package

The quantity of solid hazardous chemicals not in tanks or packages such as a stockpile is the undivided mass of the goods in kilograms.

Exemption for tank placards at service stations

Information placards are not required for underground flammable liquid tanks at fuel retailers (i.e. service stations). An exemption is provided for fuel retailers storing flammable liquids in underground tanks used to refuel vehicles in clause 350 (3) (b) of the WHS Regulation.

However, this exemption is not applicable to flammable gases such as LPG and does not extend to production facilities, works depots or fuel distributors. Underground tanks at these locations must be identified using information placards. An example is illustrated on the right where a plan is provided with the placards clearly identifying the products.

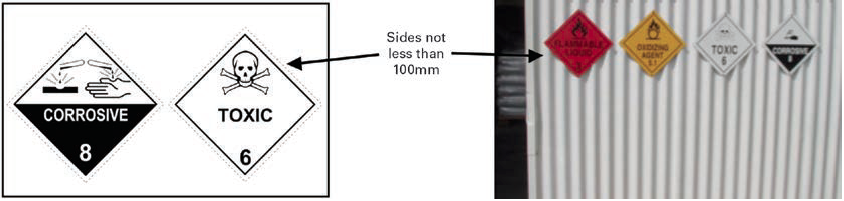

3.1.3 Information placards for hazardous chemicals in packages

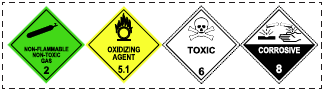

Packaged hazardous chemicals are containers of Schedule 11 hazardous chemicals in containers having a capacity of 500L or less or a net mass not exceeding 500kg. This includes drums and cylinders. Individual storage areas where hazardous chemicals in packages are kept must display an information placard when the prescribed placarding quantities in Schedule 11 table are exceeded. The form and dimension of placards for hazardous chemicals in packages are shown in Figure 5.

Figure 5: Example placards for a storage location for hazardous chemicals in packages

The placard must have a white or silver background and be large enough to accommodate the number of Class labels required to be displayed on it. The class labels ('diamond') must have sides of at least 100mm long.

The Class labels required by the WHS Regulation should be grouped together. They need not be placed in the one horizontal line on a shared sign as illustrated in Schedule 13 of the WHS Regulation, provided they are clearly visible against a contrasting background. Vertical or diagonal grouping is equally acceptable.

Note that the information placard for a package store does not require the HAZCHEM code.

Combustible liquids in packages

Placards for Category 4 flammable liquids (ie C1 combustible liquids having a flash point greater than 60°C and ≤93°C) must have the words COMBUSTIBLE LIQUID in lettering not less than 100mm high in black on a white or silver background. Figure 6 below illustrates the form and dimension required.

Figure 6: Placard for combustible liquids

Schedule 13 clause 6 (3) (b) requires a Class 3 label to be displayed when packages containing combustible liquids are stored with packages containing flammable liquids. A combustible liquid placard will not be applicable in this case.

GTDTBT in packages

Where GTDTBT are stored in packages exceeding the prescribed placarding quantity, the label shown in Figure 4 will be required along with any other applicable class labels.

Placards for IBCs stored in a package store

When a Schedule 11 hazardous chemical is contained in an IBC intended for transport and not intended for use at the workplace, the IBC must display a tank placard and the storage area must be placarded as required for a package store as per Schedule 13 (6), ie the appropriate Class label (ie 'diamond') at the entry to the storage area and adjacent to the goods.

3.2 Location of placards

Requirements for locations of placards are specified in clause 1 of Schedule 13. An outer warning placard must be displayed on every entrance to a workplace where an emergency services may enter the workplace so that it is clearly visible from normal approaches.

Information placards must be located within the workplace at the relevant storage location so that they are clearly visible from normal approaches. For hazardous chemicals stored in an indoor area, the information placards must be located:

- at the main point of entry to the building where the goods are stored

- either at every entry to a room or area where the goods are stored or adjacent to them.

For hazardous chemicals stored in an outdoor area, the placard must be located either adjacent to them, or when storage is a tank, on the external surface of the tank or adjacent to the tank.

The warning placard must be positioned separately from any other sign or notice so that the placard is not capable of being confused with the other sign or notice. Placards must be kept legible and unobstructed.

For those storage and handling areas where there is regular variation in the types of hazardous chemicals (for example, in transit storage locations and transport storage areas), it may be more convenient to use frames for slip-in/slip-out labels that are commonly used on vehicles for the transport of dangerous goods. In locations where the public may have access to the placards, labels that attach more permanently will be required.

3.3 When placards are required and which type for package stores

To identify the placarding for a package store, the quantity of hazardous chemicals for each GHS category at the workplace must be determined and compared with the prescribed placarding quantity in column 3 of the Schedule 11 table. For the purposes of this calculation, all hazardous chemical packages should be assumed to be full, even if they are not.

How to calculate quantity of hazardous chemicals in packages

- For solids, the quantity is to be calculated by the net mass in kilograms of the goods in the package.

- For liquid goods, the quantity is to be calculated by the net capacity in litres of the package.

- For gases, the quantity of gas in a package (eg cylinder) is based on the water capacity (WC), which refers to the number of litres of water that would be required to fill the cylinder. However, the labelling usually indicates the mass of gas they are intended to hold. To determine the volume of a gas cylinder, look for the stamp on the cylinder neck or foot ring, usually accompanied by a 'WC' mark. An example is shown in Figure 7. Confirmation of the water capacity of a gas cylinder may also be obtained from the supplier. Aggregate quantities for each GHS category for gases will need to be determined for comparison with the prescribed quantities. Placards required for gases are shown in the table in Appendix 1.

Figure 7: Gas cylinder and a close-up view showing WC value

WC: water capacity of a gas cylinder (ie package)

How to calculate quantity of articles or things

The quantity of hazardous chemicals that are part of an article or thing is the net quantity of that part of the article or thing that is hazardous chemicals. For example, number of litres of acid in a wet-acid battery.

4. Examples for placarding determination

Example 1

A pool shop stores the following stated dangerous goods in packages:

| Proper shipping name | UN number | Class | Packing group | Quantity (kg or L) | Placard quantity | Exceeded? |

|---|---|---|---|---|---|---|

| sodium dichloroisocyanurate | 2465 | 5.1 | II | 300 | 250 | Y |

| trichloroisocyanuric acid | 2468 | 5.1 | II | 200 | 250 | N |

| calcium hypochlorite | 2880 | 5.1 | II | 300 | 250 | Y |

| hydrochloric acid | 1789 | 8 | II | 200 | 250 | Y for combination ofPG II and III (1000) |

| hypochlorite solution | 1791 | 8 | III | 900 | 1000 |

1. Outer warning placard

2. Information placard for hazardous chemicals stored in packages displaying ADG code class labels for class 5.1 and 8 at the storage area.

Example 2

A company which supplies chemicals for dry cleaning and laundry facilities stores the following hazardous chemicals in packages and combustible liquid in a tank:

| Proper shipping name | UN number | Class | Packing group | Quantity (kg or L) | Placard Quantity | Exceeded? |

|---|---|---|---|---|---|---|

| Freon (Gas under pressure) | 1078 | 2.2 | N/A | 1200 | 1000 | Y |

| White spirit (in cabinet) | 1300 | 3 | III | 200 | 1000 | N |

| Hydrogen peroxide | 2014 | 5.1 | II | 500 | 250 | Y |

| Perchloroethylene | 1897 | 6.1 | III | 1200 | 1000 | Y |

| Hydrochloric acid | 1789 | 8 | II | 100 | 250 | Y for a combination of PG II and PG III 1000L |

| Sodium hydroxide | 1824 | 8 | II | 100 | 250 | |

| Sodium hypochlorite | 1791 | 8 | III | 800 | 1000 | |

| Phosphoric acid | 1805 | 8 | III | 100 | 1000 | |

| Diesel fuel | Combustible liquid in a tank | 12,000 | 10,000 | Y | ||

Thus, the following placards are required:

1. Outer warning placard

2. Information placards for a combustible liquid in bulk (tank)

3. Information placard for various hazardous chemicals stored in packages displaying class labels for classes 2.2, 5.1, 6.1 and 8

Example 3

The following tanks are located at a fuel retailing premises used for refuelling vehicles (ie service station):

| Tank ID | Product name | Class | Sub risk(s) | UN number | Packing group | Type | Capacity |

|---|---|---|---|---|---|---|---|

| DG T1 | LP gas | 2.1 | n/a | 1075 | n/a | a/g | 3000L |

| DG T2 | Petrol | 3 | n/a | 1203 | II | u/g | 30,000L |

| DG T3 | Diesel | C1 Combustible liquid | a/g | 20,000L | |||

u/g: underground, a/g: above ground

The workplace exceeds placarding thresholds so an outer warning placard would normally be required however a exemption now applies for service stations (fuel retailers only) so that the outer warning placard is no longer required.

An information placard is required for the diesel tank as it is in an above ground bulk container. An information placard is also required for the Class 2.1 LP Gas above ground tank. As the petrol tank is used for storage in an underground tank at retail premises for refuelling purposes, an information placard is not required as per WHS Regulation 350(3)(b).

In this example, the outer warning placard is no longer required at a fuel retailer.

Thus, the following information placards are required:1. Above ground tank displaying a Class 2 label

5. Further information and assistance

Consultants and industry associations

For consultants specialising in fuel systems, refer to the Australian Petroleum Industry Contractors and Suppliers Association (PICSA) at apicsa.com.au. There is a list of New South Wales contacts under the member directory section.

Another organisation that can assist with consulting services is the Australasian Institute of Dangerous Goods Consultants which again provides a contact list at aidgc.org.au.

Manufacturers, suppliers and local distributors may be able to provide technical assistance regarding their products, including the provision of Safety Data Sheets.

SafeWork NSW

For further information on the Work Health and Safety Act 2011 and Work Health and Safety Regulation 2017, visit safework.nsw.gov.au or call 13 10 50.

Appendix 1 – Schedule 11 of the WHS Regulation

Placard quantities and type for package stores

| Column 1 | Column 2 | Column 3 | Column 4 | Placard to display |

|---|---|---|---|---|

| Item | Description of hazardous chemical | Placard quantity | ||

| 1 | Flammable gases | Category 1 | 200 | |

| 2 | Gases under pressure | With acute toxicity categories 1, 2, 3 or 4 Note: Category 4 only up to LC50 of 5000 ppmV | 50 | |

| 3 | With skin corrosion categories 1A, 1B, 1C | 50 | ||

| 4 | Aerosols | 5000 | If any 2.1 present, else 2.2 (green class label) shown below | |

| 5 | Not stated elsewhere in this table | 1000 | ||

| 6 | Flammable liquids | Category 1 | 50 | |

| 7 | Category 2 | 250 | ||

| 8 | Category 3 | 1000 | ||

| 9 | Any combination of chemicals from items 6 to 8 where none of the items exceeds the quantities in column 4 on their own | |||

| 10 | Category 4 | 10,000 | COMBUSTIBLE LIQUID | |

| 11 | Self-reactives substances | Type A | 5kg or L | |

| 12 | Type B | 50kg or L | ||

| 13 | Type C to F | 250kg or L | ||

| 14 | Flammable solids | Category 1 | 250kg or L | |

| 15 | Category 2 | 1000kg or L | ||

| 16 | Any combination of chemicals from items 12 to 15 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

| 17 | Pyrophoric liquids and solids | Category 1 | 50kg or L | |

| 18 | Self-heating substances and mixtures | Category 1 | 250kg or L | |

| 19 | Category 2 | 1000kg or L | ||

| 20 | Any combination of chemicals from items 17 to 19 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

| 21 | Substances which in contact with water emit flammable gas | Category 1 | 50kg or L | |

| 22 | Category 2 | 250kg or L | ||

| 23 | Category 3 | 1000kg or L | ||

| 24 | Any combination of chemicals from items 21 to 23 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

| 25 | Oxidising liquids and solids | Category 1 | 50kg or L | |

| 26 | Category 2 | 250kg or L | ||

| 27 | Category 3 | 1000kg or L | ||

| 28 | Any combination of chemicals from items 25 to 27 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

| 29 | Organic peroxides | Type A | 5kg or L | |

| 30 | Type B | 50kg or L | ||

| 31 | Type C to F | 250kg or L | ||

| 32 | Any combination of chemicals from items 30 to 31 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

| 33 | Acute toxicity | Category 1 | 50kg or L | |

| 34 | Category 2 | 250kg or L | ||

| 35 | Category 3 | 1000kg or L | ||

| 36 | Any combination of chemicals from items 33 to 35 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

| 37 | Skin corrosion | Category 1A | 50kg or L | |

| 38 | Category 1B | 250kg or L | ||

| 39 | Category 1C | 1000kg or L | ||

| 40 | Corrosive to metals | Category 1 | 1000kg or L | |

| 41 | Any combination of chemicals from items 37 to 40 where none of the items exceeds the quantities in column 4 on their own | 1000kg or L | ||

Determination of classification of flammable liquids

For this table, if a flammable liquid category 4 is used, handled or stored in the same spill compound as one or more flammable liquids of categories 1, 2 or 3, the total quantity of flammable liquids categories 1, 2 or 3 must be determined as if the flammable liquid category 4 had the same classification as the flammable liquid in the spill compound with the lowest flash point.

For example, for placarding, a spill compound containing 1000 L of flammable liquid category 2 (eg petrol) and 1000 L of flammable liquid category 4 (eg diesel) is considered to contain 2000 L of flammable liquid category 2.

1. GHS refers to the Globally Harmonized System of Classification and Labelling of chemicals.