Erecting, altering and dismantling scaffolding - Part 1: Prefabricated steel modular scaffolding

A guide developed in consultation with industry that provides practical guidance for those erecting, altering and dismantling scaffolding.

Introduction

There have been a number of incidents where lack of fall prevention systems contributed to worker injuries and there were limited practical solutions to safely erect, alter and dismantle prefabricated steel modular scaffolding.

Contributors to this guide include:

- Abigroup

- Access Guard – Platforms, Scaffolding & Edge Protection

- Boral

- Bovis Lend Lease

- CFMEU

- Clarendon Residential

- East Coast Scaffolding

- Expanded Pty Ltd

- Housing Industry Association

- Kohinor Pty Ltd

- Lipman Pty Ltd

- Marron Consultancy

- Master Builders Association NSW

- SGB Raffia Pty Ltd

- Southern Cross Construction NSW

- TAFE NSW

- Unions NSW

- Waco Kwikform

- 4Ken Pty Ltd

This guide has been developed in consultation with industry and provides practical guidance for those erecting, altering and dismantling scaffolding, and for principal contractors, employers, suppliers of scaffolds and others involved in using prefabricated steel modular scaffolding. Work health and safety regulations require the control of risk to health and safety. Following this guide is a means to achieve such compliance.

Purpose

The purpose of this guide is to provide guidance to the scaffolding industry to safely erect, alter and dismantle prefabricated steel modular scaffolding for commercial and residential buildings.

While steel is the dominant material used in the manufacture of prefabricated modular scaffolding, the concepts and procedures in this guide also apply to prefabricated modular scaffolds manufactured from other materials. However, ‘Appendix A – Scaffold design limitations’ only applies to prefabricated steel modular scaffolding.

The concepts within this guide differ from traditional scaffold erection methods, which are no longer considered acceptable. These concepts should be incorporated into scaffolding manufacturer or supplier information, and erectors’ safe work method statements.

There are risks associated with scaffolders falling through and from the scaffold. To minimise these risks, this guide requires scaffolders to install and work from fully planked platforms at vertical intervals of between 2 and 3 m (2 m where practicable), and to install guardrails and mid-rails in advance of the decking. The fully planked platforms are to remain in place until the scaffold is dismantled.

If the work activity or building design prevents fully planked platforms at 2 m intervals, eg a façade or building profile that requires the working platforms to be more than 2 m intervals for the work to be carried out – a larger interval up to 3 m may be used.

For some applications the configurations of the structure or equipment for which the scaffolding is to be installed makes it not practicable to follow the principle of installing fully planked platforms at 2 or 3 m vertical intervals. In such instances alternative safe work methods must be developed to provide an equivalent level of safety.

Scope

This guide covers the erecting, altering and dismantling of prefabricated steel modular scaffolding founded on the ground or another solid surface.

Fully decked scaffolds over 20 m in height may exceed the design strength of the system and the design should be verified by the manufacturer, supplier or an engineer competent in scaffold design.

There may be prefabricated modular steel scaffolding designs (component or site-specific configuration) that require specific erection methods. For example:

- scaffolds that require specific engineering designs, such as hung scaffolds, cantilevered scaffolds, loading platforms, birdcage scaffolds or scaffolds where the loads from one bay are transferred to the adjoining standards, eg spur scaffolds or scaffolds incorporating an access opening

- scaffolds where the fully planked platforms are installed at greater than 3 m vertical intervals.

In such situations, table 1 and the generic work sequence may not apply. However, the alternative methods must provide equivalent safety to those specified in this standard.

Definitions

For the purpose of this guide, the following definitions apply:

| Term | Definition |

|---|---|

Australian standard | a document published by Standards Australia |

base lift | the first level of transoms and ledgers above the jacks |

closed platform | a platform that is constructed and that is capable of functioning as a working platform, but is temporarily closed to any loading or access, in accordance with table 1 |

| high risk construction work | an activity defined as high risk construction work in the Work Health and Safety Regulation 2025 (WHS regulation) |

hop-up bracket (platform bracket) | a bracket that is attached to a scaffold to enable a platform to be placed adjacent to a bay of an independent scaffold |

erection platform | a temporary platform that is placed on the scaffold or temporarily constructed as part of the scaffold to assist with the installation (or removal) of the standards, transoms, ledgers, guardrails and mid-rails for the platform above. Figures 1, 2, 3 and 4 show various examples of a temporary erection platform. |

must | indicates a legal requirement under the work health and safety legislation exists and must be complied with |

principal contractor | a person conducting a business or undertaking who under Clause 293 of the WHS Regulation is, or is engaged as, the principal contractor for the construction project |

safe work method statement |

|

scaffold standard | a vertical structural member of the scaffold that transmits a load to a supporting structure |

should | indicates a recommended course of action |

solid surface | a surface with adequate stiffness and strength to sustain imposed loads from the scaffold |

temporary edge protection | a guardrail and midrail or proprietary system installed to provide fall protection for scaffolders in advance of the placement (or after removal) of the permanent edge protection |

tie bar | a member fixed to the cantilevered end of a pair of hop-up brackets to prevent the brackets from spreading and the planks from becoming dislodged |

toeboard | a scaffold plank or purpose-designed component fixed at the edge of a platform to prevent material from falling off the platform |

working face | the face of a building or structure at which the scaffold has been erected to enable work to be carried out at some stage of the project |

working platform | a platform on a scaffold, positioned at a work location for supporting personnel, equipment and materials, and used to provide a working area |

Control measures for working platforms

There should be a system in place to limit the number of platforms permitted as working platforms, and to limit the respective platform ratings, to prevent the scaffold being overloaded.

Possible systems include:

- closing off platforms at the access points by physical means

- placing signs at the access points to each platform, advising if closed or indicating the duty rating of a working platform

- assigning an on-site scaffold coordinator to the relevant contractors, to control the use of various platforms, or sections of platforms

- designating who is to use the scaffold at any given time

Principal contractors must clearly identify in their written WHS management plan those responsible for implementing the control measures.

The system should also:

- include in the site induction the control measures and the names of those persons responsible for implementing the controls

- have means to identify working platforms that are closed – this can be discussed at regular toolbox meetings

- have means to monitor and review the control measures regularly – if the control measures are not effective, they should be modified, and records of the monitoring and modifications should be kept

Table 1 outlines the permitted number and ratings of platforms for various scaffold heights. For scaffolds with greater structural capacity than given by the design limitations in appendix A, the supplier may provide a revised version of table 1 based on an engineering review of their specific scaffold.

Erecting, altering and dismantling

Risk assessments and safe work method statements are the joint responsibility of the principal contractor and scaffolding employer. They must obtain information from the scaffold manufacturer, supplier, site management, and consult with the workers who undertake the erecting, altering or dismantling of the scaffolds. This information must be considered when preparing site-specific safe work method statements.

For safe completion of the work, consider the following:

- pass scaffold items – do not throw them

- the scaffolder must work from a safe position when installing edge protection for the platform above, eg by:

- standing on an erection platform with edge protection (see figures 1, 2, 3 and 4 for various examples of erection platforms)

- erecting temporary edge protection from the work platform below (see figure 5 for an example of proprietary temporary edge protection) and working behind it to install or remove the permanent edge protection. (The sections below provide design criteria for temporary edge protection and erection platforms).

- the scaffolder should be supported on a fully planked platform when installing the platform immediately above, except for platform spacings above 2 m where another purpose-made erection platform may be required for platform installation

- the fully planked platforms should be nominally 2 m apart, vertically, and remain in place until the scaffold is dismantled

- the first platform can be up to 3 m above the ground or supporting surface, except for the access bay

- safe access must be provided up to the first platform and between platforms on the scaffold

- risks from overhead power lines must be assessed and controlled – see the Code of practice: Work near overhead power lines

Design criteria for erection platforms

Erection platforms should comply with the criteria given below.

Type of erection platform | Criteria |

|---|---|

Ladder-based erection platforms (for scaffolding platform spacing of up to 3 m, ie erection platform max 2 m in height) | Load rating: minimum 120 kg. Stiles: minimum spacing 350 mm. Non-slip feet: should comply with clause 2.5.3 of AS/NZS:1892 part 1 or 3. Platform area: minimum 350 mm wide x 300 mm deep, including the ladder rung if it is at the same level as the platform. Unless the erection platform complies with the stability requirements of section 5 of AS/NZS: 1892 part 1 or 3 (clauses 5.2 to 5.4), means should be provided to secure the platform to the scaffold, eg hooking onto the guardrail. For erection platforms up to 1.2 m in height, incorporate a built-in mid-rail on the three non-access sides. For single ladder types the continuing stiles are considered as mid-rails. For erection platforms between 1.2 m and 2 m in height, incorporate guardrails on the three non-access sides. |

Erection platforms supported on ledgers/guardrails (suitable for scaffolding platform spacing of up to 2 m) | Load rating: minimum 120 kg Erection platform area: minimum 500 mm x 600 mm. On scaffolding edge sides, incorporate a built-in mid-rail. |

Scaffold planks supported on temporary transoms (suitable for scaffolding platform spacing of up to 2 m) | Platform area: minimum 2 x 225 mm wide scaffold planks. |

Design criteria for temporary edge protection

Temporary edge protection should meet or exceed the strength requirements for guardrails and mid- rails specified in Australian and New Zealand Standard AS/NZS 1576 Scaffolding – Part 1: General requirements and should be designed to allow the installation and removal of the permanent guardrails whilst it is in position. The manufacturer should provide operating instructions.

Generic work sequence - scaffold erecting and dismantling for 2 m vertical platform intervals

Where work methods differ from the generic work sequence below alternative methods should provide an equivalent level of safety to those specified in this guide.

| Task (break the job down into steps) | Activity | |

|---|---|---|

Base out scaffold and erect base lift and first lift |

| |

Complete first lift |

| |

Erect next lift from a platform | Working from a fully planked platform on the first lift, install standards (where the standard joint is 1 to 1.5 m above the platform level), transoms, ledgers and hop-ups for the next lift above. Where using erection platforms

| |

Where using temporary edge protection

Scaffold should be erected as close as practicable to the working face. Where the scaffold is greater than 225 mm from the working face, install guardrails and mid-rails to the inner face standards. | ||

Erect next lifts |

| |

Dismantle scaffold | General precautions

| |

Dismantling sequence Note: Follow the below dismantling sequence if you are using erection platforms. If you are using a temporary edge protection system, modify the dismantling sequence to suit.

| ||

Generic work sequence - specific tasks

Task (Break the job down into steps) | Activity |

|---|---|

Raise the platform 1 m from a fully planked platform (this applies to platforms five planks wide) |

Note: If a three-plank platform is used, an alternative method must be devised. |

Lower the 1 m platform (this applies to platforms five planks wide) |

|

Install ties |

|

Install anchors for ties (where used) |

|

Erect and move hop-up brackets and tie bars |

|

Install access |

|

Fix containment sheeting, eg chain wire mesh and shade cloth (where used) |

|

Erect mesh panels (where used) |

|

Erection platform options

Figure 1: Diagrammatic illustration of erection and dismantling using various erection platform options – one-man operation. Note: scaffold is shown against a building, so guardrails only needed on external face. Toeboards omitted for clarity.

Figure 1: Diagrammatic illustration of erection and dismantling using various erection platform options – one-man operation. Note: scaffold is shown against a building, so guardrails only needed on external face. Toeboards omitted for clarity.

Figure 2: Diagrammatic illustration of erection and dismantling using various erection platform options – two-man operation. Note: Scaffold is shown against a building, so guardrails only needed on external face. Toeboards omitted for clarity.

Figure 3: Diagrammatic illustration of an erection platform option for a five-plank-wide scaffold.

Note: Scaffold is shown against an existing building, so guardrails only needed on external face. Access ladder and toeboards omitted for clarity.

Figure 4: Diagrammatic illustration of an erection platform option for a three-plank-wide scaffold. Note: Scaffold is shown against a building, so guardrails only needed on external face. Toeboards omitted for clarity.

Note: Toeboards and lower mid-rails omitted for clarity.

Note: Toeboards and lower mid-rails omitted for clarity.

Note: Proprietary temporary edge protection systems such as that illustrated above require a safe work method statement and the scaffolders to undertake training to use the system safely.

Appendix A - permitted scaffold configurations

The permitted scaffold configurations are intended to assist those erecting less complex scaffolds to do so without having the structural capacity of their scaffolds checked by an engineer.

Table 1 applies to all scaffolds that fit within the below design assumptions. For scaffolds with greater structural capacity or that otherwise do not comply with the design assumptions, a revised version of table 1 may be developed based on an engineering review of the specific scaffold system.

Common issues where engineering review is required due to non-compliance with the design assumptions are:

- use of three-board hop-up platforms

- use of non-porous containment sheeting

- erection in high wind areas, eg coastal or cliff edges

- thinner wall tubing

Design assumptions

- standards are manufactured from tube 48.3 mm od x 4 mm wall thickness and minimum steel grade c250 (minimum yield strength)

- scaffold is erected nominally plumb and standards are free of bends and damage

- maximum height to the top working platform is no more than 20 m

- bay size is not exceeding 2.4 m x 1.3 m approximately

- number of fully planked platform levels is not more than 10

- number of hop-up platforms is not more than 10 – hop-up platforms may be capable of supporting one or two planks wide (about 450 mm)

- live load (duty rating), uniformly distributed over the working platform, does not exceed permissible duty rating as outlined in table 1

- working platforms supported by hop-up brackets are not loaded to more than light duty, regardless of the duty rating of the working platform in the adjoining scaffold bay

- number of permitted loaded working platforms and platforms supported by hop-up brackets are not greater than those shown in table 1

- where specified, scaffold is sheeted with chain-wire mesh and 20 per cent porosity (minimum) shade cloth

- the maximum vertical extension of a clad scaffold above the highest tie does not exceed 2 m, with all standards above the tie being full standards without any joints

- wind load is imposed by a wind speed not exceeding 60 kph (16 m/s) acting at 90 degrees directly onto the scaffold face – this design assumption does not allow a scaffold to be erected near a cliff edge or any other area where high winds are likely to occur during the time the scaffold is being erected, used or dismantled (this assumption also applies to incomplete scaffolds)

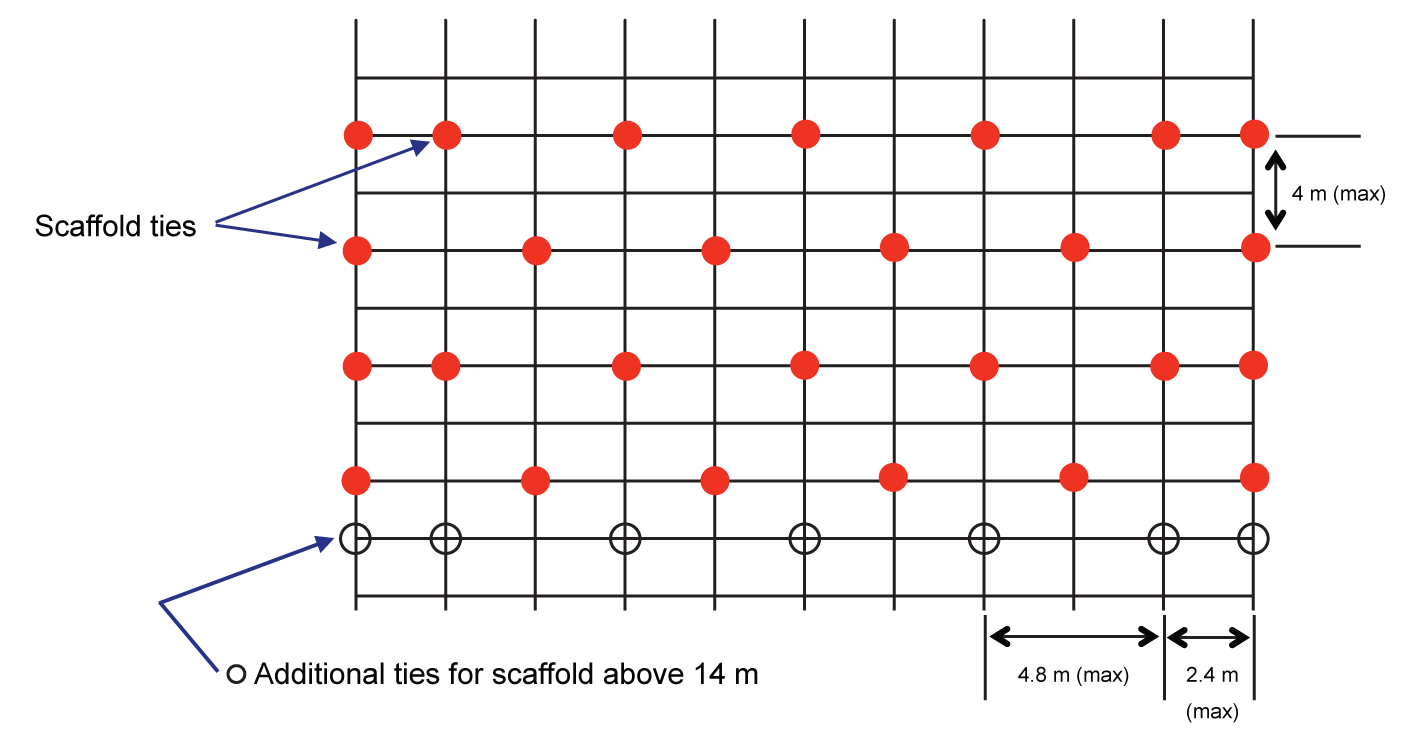

- every second standard is tied to a supporting structure of adequate strength, at 4 (maximum) vertical intervals

- or scaffolds with a fully planked platform above 14 m, additional ties are placed as per figure 6

- the foundation or footing has adequate bearing capacity to support the imposed load from the scaffold (refer to Australian Standard AS4576: Guidelines for Scaffolding)

Variations to the above design assumptions will require a detailed structural analysis by a structural engineer with a sound knowledge of scaffolding.

Permitted scaffold configurations

Check that the installed scaffold conforms to the design assumptions before using the information in the table below.

Working platforms of various duty ratings may be provided at various levels so long as the platforms within any bay comply with a row from table 1. Figure 6a shows an example of how different duty loads or closed platforms may be applied along the run of the platform.

The full run of the platform does not have to be classified as a working or closed platform.

Closed working platforms must not be used as access to a working platform.

Table 1

Max height (m) to top platform | Max number of fully planked platforms | Max number of planked hop-up platforms 1 or 2 planks wide | Permitted number of loaded platforms within the scaffold bay | Permitted number of loaded hop- up platforms 1 or 2 planks wide (light duty only) | ||

|---|---|---|---|---|---|---|

Heavy duty (675 kg) | Medium duty (450 kg) | Light duty (225 kg) | ||||

20 | 10 | 10 | 1 | 0 | 0 | 1 |

20 | 10 | 10 | 0 | 1 | 1 | 1 |

20 | 10 | 10 | 0 | 0 | 2 | 1 |

16 | 8 | 8 | 1 | 0 | 1 | 1 |

16 | 8 | 8 | 0 | 2 | 0 | 2 |

16 | 8 | 8 | 0 | 1 | 1 | 2 |

12 | 6 | 6 | 1 | 1 | 0 | 2 |

12 | 6 | 6 | 1 | 0 | 2 | 2 |

12 | 6 | 6 | 0 | 2 | 1 | 2 |

12 | 6 | 6 | 0 | 1 | 3 | 2 |

6 | 3 | 3 | 2 | 0 | 0 | 2 |

Table 1: Permitted number of loaded platforms and hop-up bracket platforms

Note:

- read across the table for each variation of permitted number of loaded platforms and hop-up platforms (eg see the bold figures)

- platforms within the bay must not be loaded to greater duty loading than shown in the table

- load on hop-up platforms must not be greater than light duty loading

Figure 6: Diagrammatic illustration of a typical tie pattern

Bay no | 1 | 2 | 3 | 4 | 5 | 6 | etc |

|---|---|---|---|---|---|---|---|

etc | |||||||

5 | HD | HD | C | C | C | C | |

4 | C | C | C | C | HD | MD | |

3 | C | C | HD | HD | C | C | |

2 | C | C | C | C | C | LD | |

1 | C | C | C | C | C | C | |

Level |

Table 6a: Example of staggered work platforms, based on direct access from the building to each platform.

| Acronym | Definition |

|---|---|

C | Closed duty |

HD | Heavy duty |

MD | Medium duty |

LD | Light duty |

Legend for table 6a

Appendix B - checklist

The following checklist can be used by a person in control of preparing for the erection, alteration and dismantling of a scaffold to ensure the important safety features and procedures specified in this guide are in place. It should be used prior to work being undertaken.

Tick yes or no as appropriate against each item. By reviewing and completing this checklist with all ‘yes’ answers, you will be well on your way to achieving your legal obligations.

Where you answer ‘no’ to any item, you should ensure that the item is still addressed to meet your legal obligations.

Scaffold configuration and design checklist

Scaffold configuration and design | Yes | No | Comment |

|---|---|---|---|

Is the maximum height to the top working platform no more than 20 m? | |||

Are standards manufactured from tube 48.3 mm OD x 4 mm wall thickness and minimum steel grade C250? | |||

Is the bay size 2.4 m x 1.3 m or less (approximately)? | |||

Is the number of fully planked platforms 10 or less? | |||

Are there 10 or less available hop-up brackets capable of supporting platforms? | |||

Are the hop-up brackets suitable for no more than two planks (about 450 mm width)? | |||

Is live load uniformly distributed over the working platform – and not exceeding permissible duty rating as outlined in table 1? | |||

Are the number of fully planked platforms and hop-up platforms, and their associated duty ratings, in accordance with table 1? | |||

Are working platforms supported by hop-up brackets not loaded to more than light duty, regardless of the duty rating of the working platform in the adjoining scaffold bay? | |||

Is scaffold containment sheeting (eg chain wire mesh and shade cloth), if provided, at least 20 per cent porous? | |||

Has every second standard been tied to a supporting structure of adequate strength at (maximum) 4 m vertical intervals? | |||

For scaffolds greater than 14 m in height to the top working platform, is an extra row of ties fitted near the base of the scaffold, as shown in figure 6? | |||

Are standards with containment sheeting attached extending no more than 2 m above the highest ties? | |||

For standards supporting sheeting, are all the joints below the top working platform? Are ties staggered, as far as reasonably practicable? | |||

Have joints in the standards been staggered, as far as reasonably practicable? | |||

Is the foundation or footing adequate to support the imposed load? Note: If in doubt, get expert advice. | |||

Are fully planked platforms at every 2–3 m apart vertically? |

Site management checklist

Site management | Yes | No | Comment |

|---|---|---|---|

Is there a WHS management plan on-site that clearly identifies those responsible for implementing control measures in relation to scaffolding? | |||

Does the site-specific induction include the names of all persons responsible for implementing control measures in relation to scaffolding? | |||

Has a documented site-specific risk assessment been undertaken to ensure that scaffolding is not erected near a cliff top or other high wind area? | |||

Are site-specific hazards, eg proximity to powerlines – and control measures included in the scaffolding safe work method statement? | |||

Is there a system in place to inform workers which platforms are working platforms or closed platforms, eg scaffolders to provide information and in turn this information to be provided to workers through regular toolbox meetings? | |||

Is there adequate supervision to ensure that the control measures are monitored for effectiveness and modifications are recommended when appropriate? | |||

Are scaffold inspection records available and maintained by the principal contractor? |

Appendix C - further information

- visit safework.nsw.gov.au

- contact SafeWork NSW online or call 13 10 50

- for technical specifications on scaffold, contact your local manufacturer

Approved industry code of practice

- Code of Practice: Work near overhead power lines (chapter 6 – scaffolding).

Australian standards

Australian Standards can be purchased from Intertek Inform. Contact the Customer Service Centre on 13 12 42 or visit the Intertek Inform website.

Check if any updates or additions to the Australian Standards have been made to:

- AS/NZS 1576: Part 1: Scaffolding – General Requirements

- AS/NZS 1577: Scaffold decking components

- AS/NZS 1892.1: Portable Ladders – Metal

- AS/NZS 1892.3: Portable Ladders – Reinforced Plastic

- AS/NZS 4576: Guidelines for Scaffolding

Catalogue No. WC02373 © Copyright SafeWork NSW 01 2016