How to manage and control the risks from working with engineered stone

How to manage and control the risks from working with engineered stone

- WHS Act section 17 - Management of risks

Risks arising from working with engineered stone must be eliminated or minimised so far as is reasonably practicable to protect workers and other persons against harm.

Risk management is a proactive, systematic process that helps a PCBU plan and respond to potential hazards and their associated risks in the workplace. It involves four steps:

- identifying the hazard

- assessing the risk

- controlling the risk, and

- reviewing control measures.

On this page

- 4.1. Identifying the hazard

- 4.2. Assessing the risks

- 4.3. Silica dust control plan

- 4.4. Controlling the risks

4.1. Identifying the hazard

A hazard is a situation or thing that has the potential to harm a person.

For engineered stone, the hazard is the silica dust generated through certain mechanical processes.

To identify the likely sources of silica dust, it is important for a PCBU to consider the following aspects of the workplace and their interactions:

- the design and manufacture of the engineered stone, including the percentage of crystalline silica

- physical work environment

- for example, the layout of a workshop

- equipment, materials and substances used

- for example, using angle grinders

- work tasks and how they are performed

- for example, grinding engineered stone which generates silica dust

- work design and management

- for example, a lack of consideration of the product supply chain and lifecycle when designing good work practices and product risk management, and

- worker experience, knowledge and behaviours.

This may be achieved by:

- conducting a walk-through assessment of the workplace

- observing the work and talking to workers and/or HSRs about how work is carried out

- inspecting the plant and equipment that is used as part of the fabrication and other relevant processes

- for example, hand-held tools may generate more silica dust than automated machinery

- undertaking air monitoring at the workplace

- inspecting workplace surfaces for build-up of settled dust, and

- reading product labels, safety data sheets and manufacturers’ instruction manuals.

4.2. Assessing the risks

A risk assessment involves considering what could happen if a worker is exposed to a hazard and the likelihood of it happening.

Hazards have the potential to cause different types and severities of harm, ranging from minor discomfort to a serious injury, illness, disease or death. Exposure to silica dust can adversely affect a worker’s health, including developing silicosis, progressive massive fibrosis, chronic obstructive pulmonary disease, chronic bronchitis and lung cancer.

Assessing the risks will help to:

- identify which workers are at risk of exposure to silica dust

- determine what sources and processes are causing that risk

- identify what kind of control measures should be implemented to control the risk

- check the effectiveness of existing control measures to control the risk

- determine the severity of the risk, and

- determine how urgently action may need to be taken.

The nature and severity of risks will depend on various factors, including the:

- percentage of crystalline silica in the engineered stone

- for example, some engineered stone can have over 90 per cent crystalline silica, while others may have a lower percentage

- task being undertaken

- for example, angle grinding can generate more silica dust than other tasks

- equipment being used

- for example, hand-held tools may generate more silica dust closer to the worker’s breathing zone than automated machinery

- conditions under which the work with engineered stone is carried out

- for example, work undertaken in an isolation booth or in an open plan workshop, and

- skills, competence and experience of the worker.

The potential of exposure of administrative workers to silica dust at fabrication workplaces should also be considered. These workers may be exposed if:

- adequate controls are not implemented, and subsequent background levels of silica dust are high, or

- their roles mean they frequently access processing areas

- for example, administrative workers that frequently walk through or perform tasks in areas near where the processing of engineered stone is undertaken may be exposed to high levels of silica dust.

A PCBU should review the information on the product labels, and any available safety data sheets, to assist in determining the type and severity of the harm. The following questions may help a PCBU to assess the risk:

- How much silica is in the products at the workplace?

- How often, and for how long, might a worker be exposed to silica dust?

- What are the scenarios that may cause workers to be exposed to silica dust?

- for example, are they exposed to silica dust when it is freshly generated or during housekeeping tasks after dust has accumulated?

- Is there evidence of exposure to silica dust?

- for example, are dust clouds evident near workers when engineered stone is cut?

- What are the conditions under which the work is carried out?

- for example, is work on engineered stone carried out in an enclosed space that is isolated from workers?

- What are the skills, level of competence and experience of workers?

4.3. Silica dust control plan

A silica dust control plan is a practical tool for a PCBU that is informed by a risk assessment. It can help a PCBU identify all potential tasks that may result in exposure, or possible exposure, to silica dust and the control measures to eliminate or minimise that exposure.

A silica dust control plan should consider ways to:

- eliminate or minimise the amount of silica dust being generated and released into the air

- prevent silica dust being breathed in by workers

- clean up any silica dust, slurry or other waste produced, and

- decontaminate workers’ clothing, footwear and protective equipment.

A silica dust control plan should include details on:

- the percentage of crystalline silica in the product being used, as the higher the percentage the higher the level of silica in the dust and the greater the risk

- all sources of silica dust in the workplace

- the dust control measures implemented for each activity

- how dust control measures are integrated into daily shift routines, for example, tool box talks, pre-start checks and daily cleaning of work areas

- how air monitoring is used to assess whether the controls are working

- the systems in place to routinely inspect, maintain and monitor controls and equipment to ensure they are clean and functioning effectively

- ongoing monitoring and review strategies, particularly in response to incidents, control failure or where the workplace exposure standard is exceeded, and

- how risks, controls and any control failures, and where the workplace exposure standard is exceeded, are communicated and reported.

Where a PCBU has decided to develop a silica dust control plan, it must be developed in consultation with workers involved in carrying out the tasks and the HSR, where there is one.

A PCBU may also share the silica dust control plan with the registered medical practitioner carrying out or supervising health monitoring. This will allow the registered medical practitioner to identify any possible source of silica dust exposure, taking into account the control measures in place.

A template for a silica dust control plan is provided at Attachment B.

4.4. Controlling the risks

Hierarchy of control measures

- WHS Regulation clause 36 - Hierarchy of control measures

A PCBU must eliminate risks arising from exposure to silica dust, or if that is not reasonably practicable, minimise the risks so far as is reasonably practicable to workers and other persons at their workplace.

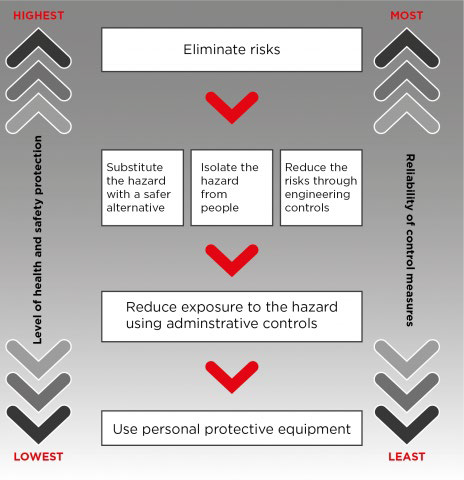

A good way to meet this duty is to apply the hierarchy of control measures (Figure 3). The hierarchy ranks control measures from the highest level of protection and reliability to the lowest.

Dry cutting, trimming, drilling, sanding, grinding or polishing engineered stone without effective controls generates very high levels of silica dust.

A PCBU must not direct or allow workers to undertake uncontrolled dry cutting or processing of engineered stone. This will expose workers and others to levels of silica dust that would be expected to exceed the workplace exposure standard and is a serious risk to health.

Figure 3: The hierarchy of control measures.

Elimination

For the purposes of this Code, elimination means completely removing all exposure to silica dust at the workplace.

For example, a PCBU can:

- not use engineered stone, or

- eliminate the need to cut, grind, trim, drill, sand or polish engineered stone during installation

Silica dust will not be generated if the engineered stone installation is completed without further cutting, grinding, trimming, drilling, sanding, or polishing on-site.

Engineered stone that has been completely fabricated in a workshop with no additional cutting or fabrication required on-site poses a minimal risk of exposure to silica dust.

Eliminate the need for cutting, grinding, trimming, drilling, sanding, or polishing during installation by:

- accurate measuring – whether by templates, diagrams or infrared measuring devices, eliminating measuring errors will eliminate the need for alterations

- cutting sink, tap and stove top holes at the fabrication workshop – mark and cut the location and size of holes during the fabrication stage or obtain the sink to ensure it fits before installation

- returning the slab to the fabrication workshop when alterations, other than minor modifications, are required, and

- consulting and communicating with principal contractors and clients to prevent alterations on-site.

If elimination is not reasonably practicable, a PCBU should consider the following controls in the order set out below:

- substitute (wholly or partially) hazards with something safer, isolate hazards from people and/or use engineering controls to minimise any risks that have not been eliminated

- then, use administrative controls to minimise any remaining risks, and

- then, use PPE to minimise any risks that still remain.

The control measures a PCBU applies may change the way work is carried out. In these situations, a PCBU must consult the workers and where applicable, their HSR, to develop safe work procedures and provide the workers with training, instruction, information and supervision on the changes.

Further guidance on the risk management process and the hierarchy of control measures is in the Code of Practice: How to manage work health and safety risks.

Substitution

Substitution is where a different product, chemical or work process is used that is less hazardous and therefore has a lower risk than the engineered stone that was previously used.

Substitution can be an effective way of managing the risk of silica dust. For example, engineered stone can be substituted with a product that contains a lower percentage of crystalline silica such as, wood or laminate.

Care should be taken to ensure any new materials that are substituted do not introduce new hazards such as other hazardous chemicals.

Isolation

Isolation is a way to separate the workers from silica dust. It is an effective control measure that can also be used in combination with engineering controls (see below) to reduce the number of workers potentially exposed to silica dust. For example, installing barriers between workers and machines that produce silica dust, both for workers generating the dust and workers nearby, such as those in adjacent offices.

Isolation can be achieved through:

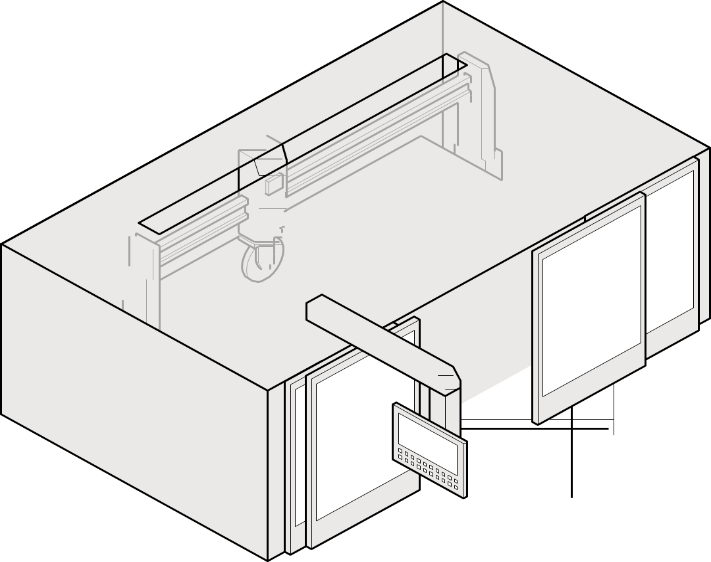

- isolating high dust generation work processes within an enclosed room with restricted access or an isolation booth (Figure 4)

- providing physical barriers and exclusion zones between different workers and workstations to prevent dust or water mist from moving into other work areas or towards other workers

- distancing a work process from other workers

- for example, consider where other workers are working when powered hand tools are used, and

- designating a room or area for other tasks such as changing or eating, away from the work area.

Figure 4: An example of an isolation booth used for automated wet cutting.

Engineering controls

Engineering controls use physical methods to change the characteristics of a task, including mechanical devices or processes that eliminate or minimise the generation of dust and minimise it becoming airborne. For example, a combination of engineering controls like LEV, on-tool extraction or water suppression may be required to minimise exposure from each dust generating process.

When considering and using engineering controls, be aware of other hazards that may be introduced. As many engineering controls are motorised, a PCBU should be aware of noise and vibration levels at their workplace and issue personal hearing protection as needed.

Water suppression

Water suppression uses water at the point of dust generation to dampen down or suppress dust before it is released into the air. Powered hand tools and equipment fitted with water feeds are available, including grinders and polishers, and large machinery including bridge saws, routers or polishing machines.

The equipment or machinery used for water suppression should:

- have an appropriate ingress protection (IP) rating for use with water suppression

- have the water feed attached and an adequate number of water feeds directed at the material and/or tool to prevent dust being released during the process

- have a consistent water flow and adequate water pressure during operation (usually at least 0.5 L/min)

- be fitted with guards, plastic flaps or brush guards designed to manage the water spray or mist containing silica dust, and

- be maintained according to manufacturer’s instructions.

Only tools and machinery that have been designed for use with water attachments should be used with water suppression. Handheld spray bottles, sponges or garden hoses are inadequate at suppressing silica dust. They are also dangerous if used with power tools that are not designed for use with water.

Additional hazards when using water suppression

While water suppressed machinery and tools provide an effective means of reducing exposure to silica dust, their use needs to be controlled to ensure other hazards are not created. Potential hazards arising from the use of water suppression are electrical hazards, water mist hazards and recycled water hazards.

Electrical hazards

A PCBU must eliminate electrical risks or, if that is not reasonably practicable, minimise the risks so far as is reasonably practicable. When working with water suppression machinery and tools, electrical hazards can be introduced. A PCBU should:

- only use tools and machinery that are specifically designed for use with water attachments

- consider the current electrical equipment’s IP rating if retrofitting or introducing water suppression into an existing process as a new control, and

- thoroughly check electrical equipment, including electrical cords, to ensure safety when undertaking wet cutting or other processing.

Water mist hazards

As a consequence of applying water to power tools with rotating blades, contaminated water mist can be generated.

This water mist can expose workers to silica dust by:

- breathing in contaminated water mist

- particle laden mist drying in the air and being breathed in, and

- particle laden mist depositing on surfaces, including clothing, and later drying, then becoming airborne again when disturbed.

Recycled water hazards

If recycled water is used for water suppression, this may introduce an additional risk for workers. Without an appropriate filtration system, there is a risk that the continual recycling of water will increase the concentration of silica dust in the water over time, and subsequently the level of silica dust in the mist generated from water suppressed activities.

More information on managing the risks of recycled water can be found in section 6.2 of this Code.

Combining water suppression with other controls

Silica dust carried in the air or in water mist generated from water suppression can be further controlled through isolation controls such as guards, enclosures and barriers. In addition to those controls, administrative controls and respiratory protective equipment (RPE) should also be used. These controls include:

- using guards, plastic flaps or brush guards around the rotating blade, tool or equipment to enclose the water spray

- providing distance between the work process and the worker

- for example, operator positioning when using bridge saws or routers

- providing distance between workers using powered hand tools and other workers in the workplace, and

- providing physical barriers between different workers and workstations to prevent the water mist moving into other work areas or towards other workers, including office workers.

Routine maintenance and cleaning will help to ensure guards continue to work effectively.

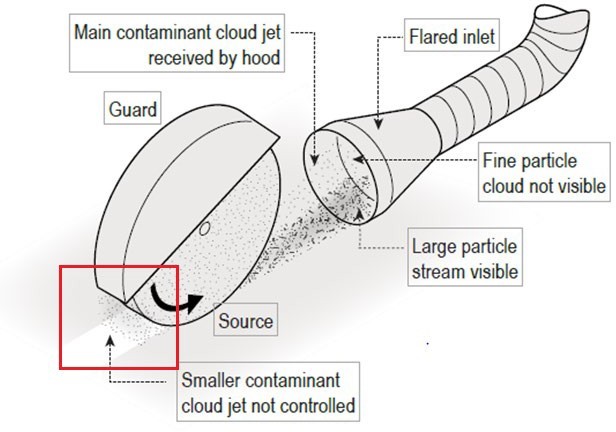

Local exhaust ventilation (LEV)

LEV is designed to remove airborne contaminants from the air before they reach the breathing zone of workers. It is the most effective control for large quantities of silica dust when it is applied close to the source of generation.

For drills, routers, saws and other equipment, an appropriately designed LEV should be fitted. The manufacturer of on-tool extraction and LEV equipment can provide information about how the equipment captures dust to determine its suitability for a particular workplace.

A simple LEV system most commonly comprises of:

- an extraction hood to capture and remove contaminated air near the point of release

- ducting to connect to an air-cleaning system

- a fan to move the air through the system, and

- an exhaust stack outside the building to disperse the cleaned air.

While these controls may reduce background levels of silica dust, they are not as effective in reducing exposure to silica dust for workers performing high exposure tasks. High exposure tasks should be performed using on-tool controls that suppress or capture dust at the source, such as integrated water suppression or dust extraction.

If there is too much distance between an extraction unit and the dust generation point, the capture strength or velocity of extraction at the point of dust generation is too low to adequately capture the silica dust generated.

For extraction to be effective, the cutting point needs to be close to the extraction hood. The nature of the work may not allow this, or it may require the worker to constantly reposition the work piece or hood. For example, a stonemason cutting a sink hole into a stone benchtop is regularly moving and turning the tool, which generates dust in a range of directions and angles.

Figure 5: Operational view of local exhaust ventilation.

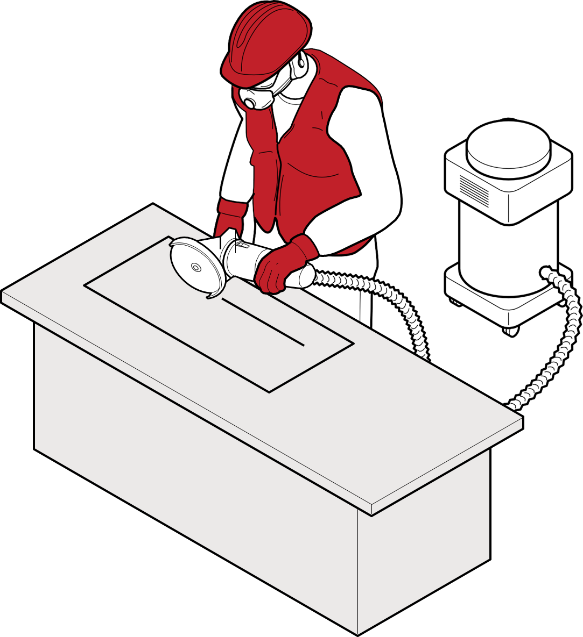

On-tool LEV

On-tool LEV systems can include a shroud, an on-tool hose attachment and a vacuum extraction system. The dust or mist is collected within the shroud and is then drawn into the hose attachment to the vacuum, where it is extracted, filtered and discharged. When correctly designed and used a LEV system can both capture and contain dust or mist generated from engineered stone (Figure 6).

Figure 6: A worker cutting/grinding with on tool dust extraction.

Where the engineered stone slab can be lifted, a sacrificial backer-board or spoil-board should be placed under it during cutting or trimming. This prevents the release of dust below the slab and increases the effectiveness of on-tool dust extraction by LEV. Medium-density fibreboard or particleboard are suitable for this purpose.

Silica dust is very abrasive to LEV equipment. Regularly inspecting LEV equipment for damage will help ensure it is effective and fit for purpose.

Natural ventilation

Improving the general ventilation to a room or building may help reduce the concentration of contaminants in the air. However, ventilation should not be relied on to ensure silica dust exposure is controlled. Other controls must also be used to prevent the release of silica dust into the air and adequately protect workers and others in the vicinity from exposure to silica dust.

The workplace should have an adequate supply of fresh air. For on-site installation, processes that generate silica dust may be undertaken outside, provided the contaminated dust does not travel in the direction of other workers or premises. When working indoors, windows and doors within a room or building should be open to provide general ventilation. Fans may support the movement of air, but it is important that air streams are directed appropriately. Fans should be arranged so that streams of clean air are drawn past workers and contaminated air streams are drawn away from workers and ensure contaminated air is not directed towards others, for example, workers or adjacent businesses.

Wet slurries should be cleaned up before fans are used to prevent them from drying and creating potential dust hazards.

More information about natural ventilation at the workplace can be found in the Code of Practice: Managing the work environment and facilities.

Administrative controls

Administrative controls are used to provide additional protection after implementing higher level controls such as substitution, isolation and engineering.

Administrative controls are work practices or procedures designed to minimise exposure to a hazard. For example, routinely cleaning the work area and vacuuming residual dust from clothing.

Due to the risks of silica dust when working with engineered stone, administrative controls on their own will not provide enough protection from exposure to silica dust. They should only be used in combination with and to support higher level control measures.

Administrative control measures rely on human behaviour and supervision to be effective.

Workshop layout

The layout of engineered stone processing workshops needs to be designed to minimise exposure to and contamination from silica dust generated in neighbourhood work areas. For example, by including enough distance between workstations and positioning work areas for each stage of processing in sequence.

Work practices

The way in which work is conducted can influence the generation of silica dust and worker exposure. While the use of higher order controls such as water suppression and LEV are critical to minimising worker exposure to silica dust, the following work practices may assist in reducing exposure:

- organise for all cutting, grinding, trimming, drilling, sanding, or polishing of engineered stone to be completed at the fabrication workshop before on-site installation

- plan cutting of engineered stone to make the minimum number of cuts for each job

- implement policies that describe actions to be taken when working with engineered stone, for example:

- wetting engineered stone before cutting, grinding, trimming, drilling, sanding, or polishing to remove dust and aid with water suppression, and

- washing engineered stone prior to and after fabrication to remove any residual dust.

- implement maintenance schedules to ensure routine, or daily checks of critical controls

- for example, guards, LEV and PPE

- implement shift rotations to make sure workers are not exposed to dust for extended periods of time

- excluding workers and others not involved with the cutting, grinding, trimming, drilling, sanding, or polishing task

- implement good housekeeping policies including regular cleaning of work areas, and

- ensure workers wash their hands and face thoroughly before eating, drinking or leaving the workplace.

Safe work procedures

Workers’ use of power tools, equipment and other machinery will influence the amount of silica dust that is generated.

Before plant or equipment is used in the workplace, workers and other persons who are to use it must be provided with the information, training, instruction and supervision necessary to protect them from silica dust and any other risks arising from its use.

Safe work procedures should be developed that include instructions on:

- the correct use of silica dust control equipment

- how to operate the plant and equipment in a manner that reduces the generation of silica dust

- how to carry out inspections, shut-down, cleaning, repair and maintenance of plant and silica dust control equipment

- emergency procedures, and

- the use of PPE, such as protective footwear, eye wear, RPE and aprons.

In addition to safe work procedures, warning signs (Figure 7) must be used to communicate silica dust hazards or the required PPE, if such signs are required to control the risks of silica dust.

Figure 7: Dust warning signs.

Personal Protective Equipment (PPE)

PPE refers to anything used or worn to minimise risk to workers health and safety, for example, protective footwear, eyewear and RPE such as powered air purifying respirators (PAPR).

If PPE is to be used to minimise the risk of exposure to silica dust, the PCBU must provide the appropriate PPE to workers at the workplace, unless this PPE has been provided by another PCBU.

PPE should only be considered after implementing substitution, isolation, engineering and administrative controls. It should only be used in combination with, and to supplement higher level control measures.

PPE should never be relied on as the sole means to protect workers from silica dust, as it does not control the hazard at the source and is the least effective at minimising risks when used on its own.

Using PPE relies on human behaviour and supervision to be effective.

Respiratory protective equipment (RPE)

It is a good idea to establish a system to manage workers’ use of RPE. The system should include:

- selecting the most suitable RPE for the task

- fit testing

- a use, maintenance, storage and repair program

- a facial hair policy for tight-fitting respirators, and

- providing information, training and supervision for workers.

Selecting suitable RPE for silica dust

A PCBU must ensure RPE is selected to minimise health and safety risks. This includes ensuring the RPE is:

- suitable having regard to the nature of the work and hazards associated with the work

- a suitable size and fit and reasonably comfortable for the worker who is to use and wear it

- maintained, repaired or replaced so that it continues to minimise risk to the worker who uses it, including by ensuring it is clean and hygienic and in good working order, and

- used or worn by the worker, so far as is reasonably practicable.

When determining suitability, the protection factor assigned to the RPE must be sufficient to provide protection. The RPE filter must also be suitable for silica dust.

When using a tight-fitting respirator, it must have an effective face seal to ensure contaminated air does not leak into the respirator and is not breathed in by the worker. This means they should be clean-shaven or only have facial hair that does not interfere with the fitting surfaces or the respirator valve. As everyone’s face is a different size and shape, there is no ‘one size fits all’ tight-fitting respirator. Fit testing each worker and their RPE before they commence dust-generating work will help ensure RPE is effective.

For workers who want to keep facial hair that may interfere with the operation or proper fit of a tight-fitting respirator (for example a closely trimmed beard), a PAPR with a loose hood may be suitable.

Workers using handheld equipment for grinding and polishing tasks, in combination with effective engineering controls, should wear respiratory protection.

The following questions should be considered when choosing RPE:

- Does the RPE provide the required minimum protection factor?

- Is it clean and well maintained?

- Was fit testing successful?

- Is it comfortable for the worker to wear?

- Does the RPE introduce additional hazards such as heat, or obscured vision?

More information about PPE can be found on the Safe Work Australia website.

Fit testing

Fit testing is essential to make sure the RPE works correctly and is comfortable to wear with other PPE that may be needed for the task. Fit testing measures the effectiveness of the seal between the respirator and the worker’s face. If there is not a good seal contaminated air, potentially containing silica dust, could leak into the respirator and be breathed in by the worker.

There are two types of fit testing that can be carried out:

- Qualitative

- a pass/fail test that relies on the wearer’s ability to taste or smell a test agent, and

- only used on half face respirators.

- Quantitative

- uses specialised equipment to measure how much air leaks into the respirator, and

- used on half face respirators, full face respirators and PAPR.

Quantitative fit testing results are more objective than qualitative testing because some workers have difficulty with their ability to taste or smell. This can result in a ‘false pass’ and worker health not being adequately protected. Full face respirators and PAPR should be fit tested using the quantitative method.

All fit testing should be carried out by a competent person, manufacturer, supplier or consultant:

- before a worker wears a tight-fitting respirator for the first time

- each time a new make or model of respirator is provided to a worker

- whenever there is a change in the wearer’s facial characteristics or features that may affect the seal

- for example, large weight loss or gain, and

- be repeated annually.

More information about who a competent person is can be found below.

For PPE to be effective, workers who are required to wear tight-fitting respirators should be clean shaven. If they cannot be clean shaven, ensure:

- there is no hair between their face and the seal of the respirator face piece as it can interfere with a proper fit. This is important as silica dust is smaller than facial hair.

- facial hair does not interfere with the inhalation/exhalation valve operation.

It is also important to ensure clothing, makeup, dental fixtures and jewellery do not interfere with the respirator seal or inhalation/exhalation valve operation.

A written record of fit tests carried out for each worker should be kept and shared with the worker after fit testing is complete. The record should include the:

- type of test performed

- make, model, style and size of respirator tested, and

- date and result of the test.

Hood and head top type PAPRs do not require fit testing as they cover the whole head and do not rely on a tight seal.

Competency of fit testers

Fit testers should be properly trained and proficient in the fit test method being used. Relevant competencies of a fit tester may include:

- knowledge of the respirators being fit tested

- knowledge of the fit test method

- ability to set up all applicable equipment and monitor its function

- ability to carry out the test and evaluate the results, and

- ability to identify likely causes of fit test failure.

Training workers on the correct use and maintenance of RPE

When issuing RPE, training must be provided to ensure that workers correctly use and maintain the RPE. Training can be carried out by:

- a health and safety consultant

- a trained person in-house

- a representative from an RPE manufacturer or supplier

- an occupational hygienist, or

- the holder of recognised qualifications in WHS with expertise or experience in this area.

Training in the use of RPE should cover the following:

- why RPE is required

- when RPE is required to be worn

- how RPE works

- the limitations of RPE

- how to correctly put on and take off RPE

- how to conduct a fit check

- how to clean and maintain RPE

- when and how to replace filters and batteries (including rechargeable batteries), and

- how and where to store RPE when not in use.

Ongoing training and supervision may be required to ensure workers correctly use RPE. Workers must also take reasonable care for their own health and safety, comply with any reasonable instruction, and cooperate with any reasonable policy or procedure of the PCBU relating to health or safety. This means a worker must use and wear RPE in accordance with any workplace policy and information, training or reasonable instruction given.

Fit checking

Fit checking enables workers to take reasonable care of their own health and safety while working with engineered stone.

A fit check is a quick check to ensure a fit tested respirator is properly positioned on the face and there is a good seal between the respirator and face. Fit checks do not replace the need for a fit test. Workers should follow the respirator manufacturer’s instructions on how to carry out a fit check.

Fit checking is the responsibility of the worker. Workers must be trained on how to carry out a fit check for their tight-fitting RPE. They should undertake a fit check every time they use a tight-fitting respirator to ensure they are using and wearing RPE in a way that will protect their health and safety.

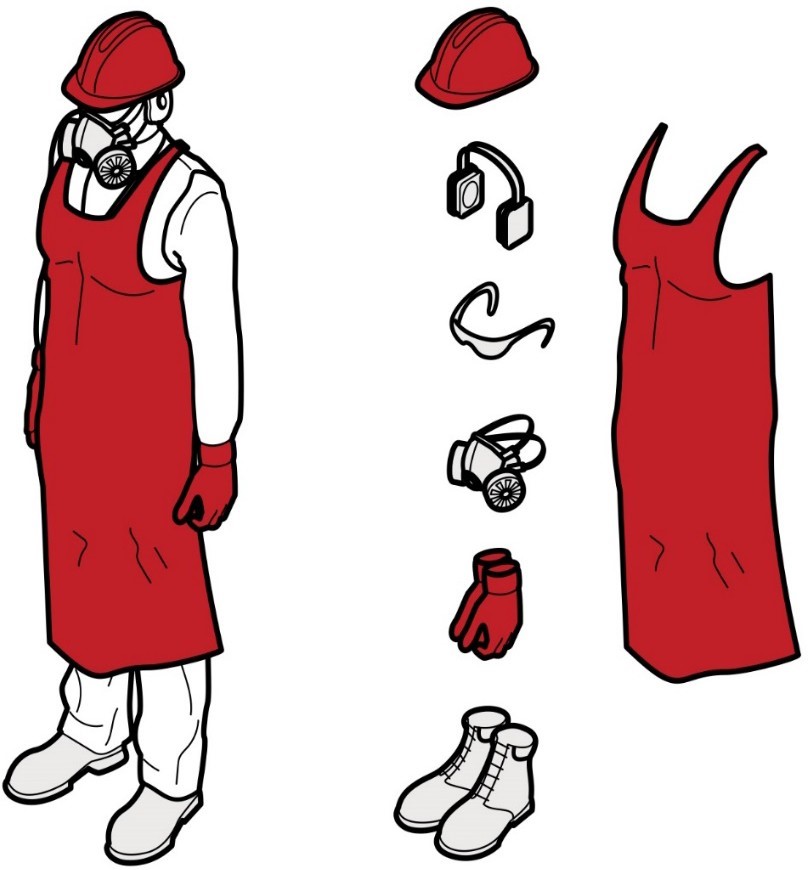

Other PPE

In addition to respirators, workers may need other PPE depending on the work task. A risk assessment should be conducted to decide the PPE required for workers.

The PCBU should assess the conditions likely to affect the health and safety of workers and ensure suitable PPE and appropriate training is provided before any work generating silica dust commences.

Other types of PPE that can be used to minimise exposure to silica dust include:

- eye protection

- gloves

- protective footwear such as rubber boots or gumboots, and

- protective clothing such as waterproof overalls or an apron (Figure 8).

Appropriate protective footwear and clothing will protect workers’ clothing from silica dust, including water and mists containing dusts. Note that the use of gloves could be an entanglement hazard when using high-speed power tools.

A hard hat and hearing protection will provide protection and may be recommended to manage other risks associated with the engineered stone fabrication process.

When selecting other types of PPE, it is important to ensure that the PPE does not interfere with the effectiveness of RPE.

Figure 8: Personal protective equipment.

Use a combination of control measures

A combination of control measures should always be used to control the risk of silica dust when working with engineered stone.

This may include a combination of isolation, engineering controls, work practices and procedures and PPE. For example, a PCBU could consider a combination of water suppression, a LEV system, shift rotation and RPE. It is recommended that with any combination of controls to minimise silica dust, that RPE is provided and worn correctly for the full duration of the task to manage any residual dust.

If a PCBU relies solely on one control measure such as PPE or water suppression alone, there may be a significant risk to their workers’ health and they may be breaching the WHS laws. It has been shown that solely relying on PPE or water suppression does not adequately protect workers from the risks of silica dust.