Forklift safety fact sheet

Operators must have a high risk work licence

No lifting of workers on the forklift load arms ore on pallets

Workers can only be lifted with a forklift truck in an approved Work Box

Forklift driver’s seat

- Must be replaced when it is damaged.

- Seat belt must be worn at, ALL times.

- Consider fitting an interlock switch to the seat belt to prevent operation of the forklift when the seat belt is not worn.

Parking the forklift

- Park on level ground

- lower the load arms

- turn off the forklift

- apply the hand brake

- remove the key

Pressure relief valve

The pressure relief valve must be located at the 12 o’clock position at all times.

Gas cylinder mounting bracket

The bracket should be checked on a regular basis to ensure that it is adequately securing the cylinder in its location.

Forklift attachments

The following information is required for attachments such as jibs, workboxes, bale grabs, slippers, drum rotators, bulka bag lifters etc

- Name & address of the attachment manufacturer or agent

- model or type number

- needs to have a serial number (if applicable) load rating for each lifting point or load centre

- horizontal and vertical centre of gravity

- the weight of the attachment

Forklifts load arms

Do not modify or damage the load arms and do not tow with them.

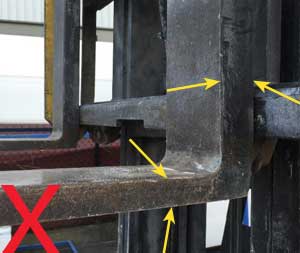

10 percent wear

The 10 percent wear is determined by measuring the vertical thickness of the load arm and then the horizontal thickness heel of the load arm. The horizontal thickness is not to exceed 10% less than the vertical thickness. The one shown is 30 percent

Pre-operation checks

Forklift safety checks are to be done at the start of each day

Warning items

- horn

- flashing light

- reversing beeper

- blue light indicators

Load rating plate

Should be readable, list the forklift capacity, list any attachment used and their working load limit (WLL) for attachments used.

Conditional plates

When a forklift is driven on a road it needs to have:

- RMS conditional plates

- head lights front and brake light and indicator lights

Load guard

- the load guard must be maintained in a good condition

- extensions could be fitted for two pallet lifts and must support ⅔ of the top load or the top layer of an unwrapped load

Load arms wear

Do not drag the forks heel on the floor. This will cause wear at the heel and the forklift must not exceed 10 percent wear. If they exceed the 10 percent wear

they must be replaced.

Traffic management plan

- Physical fences or barriers to separate forklift from pedestrians

- exclusion zones

- limit forklift speed by fitting speed limiters or using location detector that automatically adjust the forklift’s speed to the location

Maintenance

- regular maintenance must be carried out to the manufacturers requirements or a competent person

- log Book/maintenance records must be kept

Please note: This is a general guide not an extensive list of forklift related items to be checked and maintained regularly.

More information

- Forklifts

- SafeWork Australia - Forklift guides

- Call 13 10 50