Alcohol-based hand sanitiser – Work Health and Safety responsibilities

This technical guide is targeted at businesses intending to manufacture, decant, import, supply or store alcohol-based hand sanitisers. It contains important WHS information.

About alcohol-based hand sanitiser

Alcohol-based hand sanitisers generally contain between 60%-95% of ethanol or isopropyl alcohol. They are hazardous chemicals under the Work Health and Safety Regulation 2017 (WHS Regulation).

For the purposes of this guide it is assumed they are classified as Category 2 flammable liquids under the Globally Harmonised System of Classification and Labelling of Chemicals (GHS). You should verify the classification of your products in the Safety Data Sheet (SDS), or according to GHS classification criteria.

Potential hazards of alcohol-based hand sanitisers include fire, explosion, and serious eye irritation. Even small quantities of flammable vapours from a leak or spill that accumulate in poorly ventilated areas may ignite and cause serious injury and damage.

Managing hazards

You must manage all risks to health and safety associated with handling alcohol-based hand sanitisers, and ensure safe packaging, labelling and the provision of information about the product, including safety data sheets.

Responsibilities of manufacturers and suppliers

For the purposes of this guide, manufacturing includes repacking or blending alcohol with fragrances, moisturisers or other additives to produce a hand sanitiser.

Manufacturers and importers must:

- classify their product as a hazardous chemical (it is expected that most alcohol-based hand sanitisers are classified as Category 2 flammable liquids)

- prepare an SDS that meets Australian requirements, and,

- pack products in robust packaging.

This includes ensuring that hazardous chemicals are not packed into containers that usually contain food or beverages and cannot be mistakenmly identified as containing food or beverages.

Further information

Depending on the volume of the product container, the packaging may need to be approved under the Australian Code for the Transport of Dangerous Goods by Road & Rail (ADG Code).

Suppliers of alcohol-based hand sanitisers must provide a copy of the SDS when the product is first supplied to a workplace, and upon request by a person at the workplace.

SafeWork NSW: manufacturers' and importer responsibilities.

Hazardous chemical registers

All sites handling hazardous chemicals must prepare and maintain a register of hazardous chemicals.

The register is a list of the product names of all hazardous chemicals used, handled or stored at the workplace, accompanied by the current SDS for each hazardous chemical. It can be electronic or hard copy provided it is readily accessible to all workers.

More information about hazardous chemical registers can be found on the Safe Work Australia website including Safework Australia’s Hazardous chemical register template.

Placarding

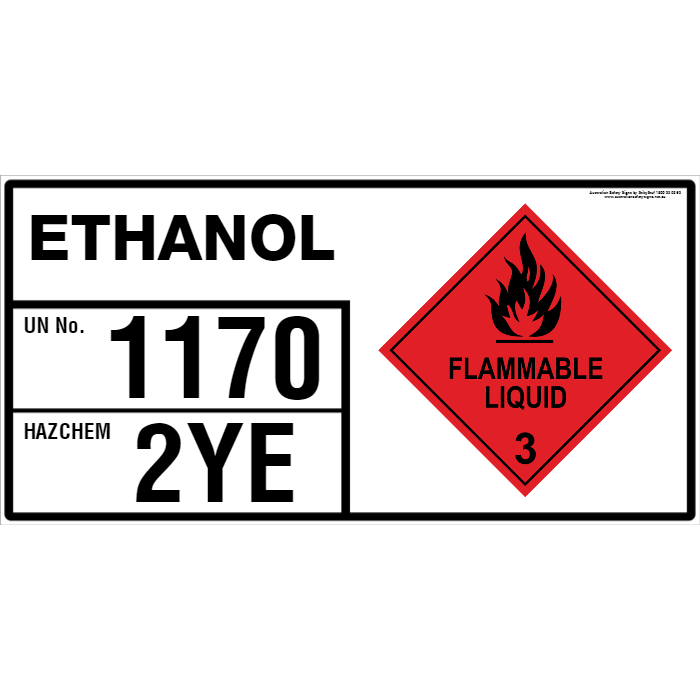

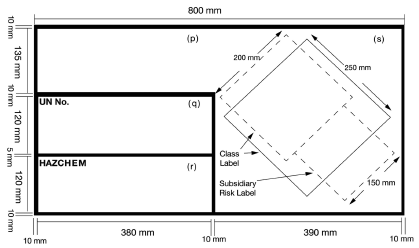

Placards must be displayed at the workplace to warn workers, visitors and emergency services of the hazard when more than 250 litres of ethanol, isopropanol or finished hand sanitiser are used, handled or stored at the workplace.

There are multiple places you must display placards:

- Outer warning ‘HAZCHEM’ placards must be displayed at the street entrances to your premises.

- Bulk placards must be attached to containers with a capacity of more than 500 kg or 500 litres. Bulk placards must also be displayed at the main entrances to any building housing a bulk container, unless the bulk container is an Intermediate Bulk Container (IBC).

- Packaged store placards are required at the main entrances to any building where more than 250 L of alcohol-based hand sanitisers are present in packages or IBCs. The minimum dimensions of the placards are 100mm x 100mm.

Packaged store placards are required at the main entrances to any building where more than 250 L of alcohol-based hand sanitisers are present.

Find out more about placarding for storage of hazardous chemicals.

Manifests and notification

If you use, handle, or store 2500 litres or more of Category 2 flammable liquids such as ethanol, isopropanol or hand sanitiser you must prepare a manifest document and notify SafeWork NSW of the quantity you are storing.

The manifest must contain a site plan and a list of all WHS Regulation Schedule 11 hazardous chemicals above placard quantities. It must be kept in a manifest box at the entrance to your premises. A manifest template can be found on the Safe Work Australia website.

In addition to a manifest, an emergency plan must be prepared and lodged with Fire and Rescue NSW (FRNSW).

For more detailed information on placarding and manifest requirements please refer to guidance from SafeWork NSW and FRNSW.

- Safe Work Australia: Example of a Manifest (Template)

- SafeWork NSW: Notifications for Schedule 11 Hazardous Chemicals and Abandoned Tanks – Guidance Material

- Fire and Rescue NSW: Hazardous Chemicals Manifest

Labelling

Cosmetics and therapeutic goods

Alcohol-based hand sanitisers of a size and type marketed to consumers must be labelled in accordance with the Australian Competition and Consumers Commission’s mandatory standard for cosmetics ingredients labelling.

Products packaged in a form to be used by health workers in a hospital or medical environment must be labelled as therapeutic goods. Refer to the guidance from the Therapeutic Goods Administration on labelling of alcohol-based hand sanitisers, including a determination issued in March 2020 about labelling of certain approved formulations.

All other products

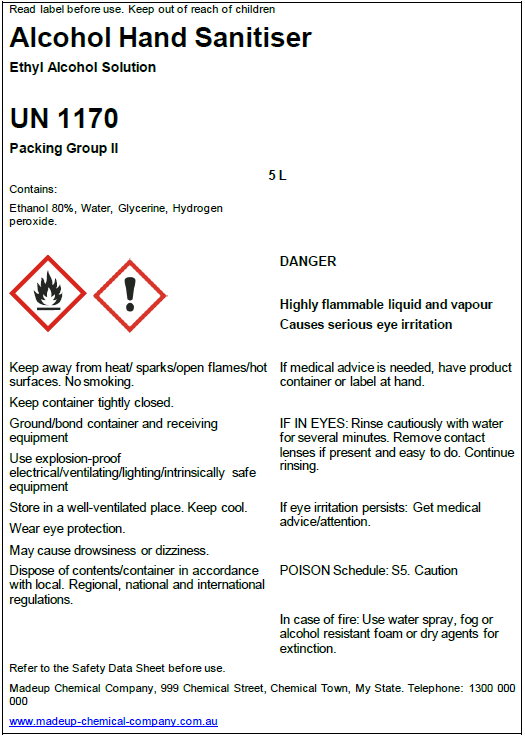

Alcohol-based hand sanitisers that do not fit in the previous two categories, such as non-consumer quantities and raw materials, require workplace labels that comply with Schedule 9 of the WHS Regulation.

It is recommended to consult the SafeWork NSW Code of practice labelling of workplace hazardous chemicals. Refer to Appendix D for hazard and precautionary statements, and Appendix H for examples of compliant labels. Below is a sample of a workplace label that complies with the Work Health and Safety Regulation.

Alcohol-based hand sanitisers in containers of 1 litre or less are entitled to relaxed labelling and packaging as personal care products in consumer packaging under Section 3.12 of the ADG Code.

Transport labels

Until 1 October 2021, hand sanitiser in containers of 1 litre or less may be entitled to be transported under the Personal Care Products in Consumer Packaging concessions contained in 3.4.12 of the ADG Code.

Products in containers of greater than 1 litre, for example 5 litre bottles in fibreboard boxes, or 1000 litre containers of ethanol, must be packed and labelled for transport as fully regulated dangerous goods. Packaging must be approved for dangerous goods, and marked with the UN number, proper shipping name, manufacturer contact details, and a class 3 flammable liquids label. The example label above can be used for a fully regulated dangerous goods package by changing the flame pictogram for a class 3 flammable liquids label.

Refer to guidance from the National Transport Commission for further information.

Controlling ignition sources

When manufacturing, decanting, bottling or storing alcohol-based hand sanitiser you must control the risks of fire and explosion associated with the generation of flammable vapours.

Examples of potential ignition sources include:

- naked flames

- smoking

- sparks

- static electricity

- hot surfaces from vehicles or plant

- portable electrical equipment (e.g. tools, radios, fans), and

- fixed electrical equipment (e.g. power sockets and wiring).

The transfer of flammable liquids

Even small quantities of flammable liquids being transferred can generate a static electrical discharge and in the presence of flammable vapours this can result in a fire. It is important that all containers involved in flammable liquid transfer are at ground potential. This can be achieved by bonding the containers using appropriate clamps and cables and connecting them to a common grounding bar or earthing point. Ensure that only competent persons are involved in the design and implementation of bonding and earthing systems for flammable liquid transfer.

Exclusion zones when opening or decanting

Opening packages or decanting flammable liquids should only be performed in an open area (such as outdoors) with a minimum 5-metre exclusion zone for ignition sources. When decanting indoors, ignition sources should be excluded from the entirety of the room and within 5 metres of any opening to the room.

Opening, decanting or bottling should not occur within 8 metres from the site boundary.

For manufacturing processes, decanting or when storing more than 100L in closed containers, you should classify a hazardous area where flammable vapour may be present and exclude all ignition sources.

WARNING: Even small quantities of spilt flammable liquid can create a vapour cloud. A fire could result if ignition sources are present.

Further guidance may be obtained from AS/NZS 60079.10.1: Explosive atmospheres – classification of areas or the SafeWork NSW Code of Practice Managing risks of hazardous chemicals in the workplace.

Fire Protection

Even small amounts of flammable liquid require fire protection to control the spread and acceleration of a fire event.

Your fire protection system should have capacity to quickly control and put out any fires from flammable liquids. Any fire protection system must be compatible with the product stored and not cause a dangerous reaction.

When storing packaged Category 2 flammable liquids indoors, the modified table from Australian Standard 1940 below should be followed for fire protection equipment:

Quantity | Fire Protection |

|---|---|

Less than 2000L | 1 x Powder-type extinguisher (minimum rating 2A 60B) 1 x Foam-type extinguisher (minimum rating 2A 20B) |

2000 to 10,000L | 2 x Powder-type extinguisher (minimum rating 2A 60B) 1 x Powder-type at each doorway (minimum rating 2A 60B) 2 x Foam-type extinguisher (minimum rating 2A 20B) Hydrants capable of 10L/s water supply |

Decanting / bottling areas | At every fill point: 1 x Powder-type extinguisher (minimum rating 2A 60B) 1 x Foam-type extinguisher (minimum rating 2A 20B) |

For storage quantities greater than 10,000L and/or manufacturing facilities, you should seek specialist advice about fire protection systems.

Spill containment

You must control the risk of spills in each part of the workplace where Category 2 flammable liquids are used, handled, stored or generated. A spill containment system must ensure that any potential spill can be retained within the workplace and safely cleaned up. You must ensure that in the event of a spill or leak that different hazardous chemicals cannot interact to create a fire, explosion, or harmful reaction.

Detailed information about the design and construction of spill containment systems can be found in AS1940.

Ventilation

Vapours from Category 2 flammable liquids are heavier than air and may accumulate along the ground and in drains or pockets of a building.

A manufacturing, decanting, or storage area without adequate ventilation creates a significant risk of fire or explosion and health hazards to workers.

If you are manufacturing, decanting or storing ethanol, isopropanol or hand sanitiser indoors you should seek the advice of a competent person to determine if the ventilation is adequate. Detailed guidance is available in AS 1940. Any ventilation equipment must be purpose built for flammable vapours. Use of equipment (e.g. fans) not designed for flammable liquids may ignite vapours.

In addition to having adequate ventilation, you should always try to minimise the risk of vapour release by:

- using enclosed systems for transfer and avoid open-top splash filling

- keeping the time for decanting and open containers to as short as possible

- immediately cleaning up spills or leaks.

Retailers

In a retail environment it is critical to safety that the quantities held in stock are kept at a volume that presents a minimum level of risk. The quantity Category 2 flammable liquids at retail premises must be consistent with the existing risks controls such as fire protection and ventilation.

It is recommended you do not exceed the minor storage quantity as per AS1940. For indoor storage of Category 2 flammable liquids in packages up to 20 litres each, that means not more than 1 L per 2m2 of floor space and not more than 250L in any 500m2 area. Greater quantities may be accommodated subject to guidance in AS1940.

The following handling requirements and precautions apply:

- persons who handle the liquids shall be fully trained about the hazards involved

- packages shall not be placed where they could hinder escape from a building in an emergency

- care shall be taken when decanting or transferring flammable liquids. Dispensing pumps or self-closing metal taps should be used, in order to reduce the hazards of splash filling, spillage and vapour escape

- packages shall be kept closed when not in use. Packages containing flammable liquids should only be opened or decanted in well-ventilated areas and away from any potential ignition source

- the area in or around the minor storage shall be kept free of combustible materials and residues

- any materials that might react dangerously if mixed shall be kept apart so that the possibility of reaction is minimised, e.g. flammable liquids and pool chlorine

- liquids should not be stored near any hot surfaces (e.g. steam pipes, furnace walls or engines) or where they might be accidentally exposed to heat (e.g. from escaping steam).

If you intend to decant into a customer provided container you must ensure the container:

- is not of a capacity considered to be bulk

- is clearly marked with the product identifier or chemical identity and the hazard pictogram

- is in sound condition

- will safely contain the chemical for the time the chemical is likely to be packed

- is made of compatible material with, and will not be adversely affected by the chemical

- does not usually contain food or beverages and cannot be mistakenly identified as containing food or beverages.

Static electricity and hand sanitisers

When using the alcohol-based hand gel sanitisers, ensure the gel is given suitable time to fully dry/evaporate. Avoid touching any surface until the gel has fully dried as a build-up of static could create an ignition source that could ignite the hand sanitiser gel leading to burns.

Further assistance

SafeWork NSW can arrange for an inspector to come to your site to offer advice or assistance. You can request an advisory visit online or contact 13 10 50.

Codes and guidance

The following codes of practice provide further information on flammable and combustible substances:

- SafeWork NSW - code of practice: Managing risks of hazardous chemicals in the workplace

- SafeWork NSW: Placarding for storage of hazardous chemicals

- Safe Work Australia: Globally Harmonised System of Classification and Labelling of Chemicals (GHS) information sheet

- Safe Work Australia’s Hazardous chemical register template

- SafeWork NSW: Code of Practice Labelling of workplace hazardous chemicals

- SafeWork NSW: Preparation of Safety Data Sheets for hazardous chemicals

- WorkCover Queensland: A guide for flammable and combustible liquids

- Therapeutic Goods (Excluded Goods—Hand Sanitisers) Determination 2020

- AS1940:2017 The storage and handling of flammable and combustible liquids

- AS/NZS 60079.10.1: Explosive atmospheres – classification of areas