Noise in the wood product manufacturing Industry: fact sheet

Noise in the wood product manufacturing industry. Workers who are exposed to high noise levels may experience serious hearing loss. This loss is gradual and workers often do not realise that their hearing is being damaged.Noise-induced hearing loss is permanent – it can’t be cured or improved.

Noise at work

Workers who are exposed to high noise levels may experience serious hearing loss. This loss is gradual and workers often do not realise that their hearing is being damaged.

Noise-induced hearing loss is permanent – it can’t be cured or improved.

Woodworking involves noisy machinery, often operating at the same time eg saws, routers, presses, sanders, compressed air, and nail guns. As a result, wood product manufacturing workplaces are one of the noisiest workplaces across NSW industries.

The cost to workers and business owners is huge and includes:

- lost jobs, reduced earnings, reduced leisure and career opportunities, loss of self-esteem and impaired family and social life

- higher workers compensation premiums, replacement and training costs for employers

- persons with noise induced hearing loss may suffer from:

- fatigue, stress and headaches

- communication difficulties eg unable to hear warning alarms, instructions and normal conversation

- social isolation and loneliness

How much noise is too much?

The level of hearing loss depends on how loud the noise is, and how long someone is exposed to it.

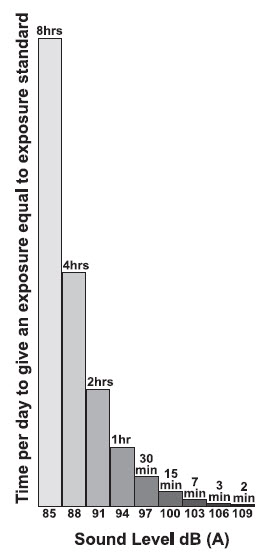

To be safe, workers must not be exposed to:

- noise levels of more than 85 dB(A) over eight hours, or

- peak (sudden loud) noises of more than 140 dB(A), eg sledge- hammer, which can cause instant damage to hearing

Note: The length of time a worker is able to work is reduced by half for every 3dB(A) increase in noise level.

Typical noise levels at woodworking machines

| Wood machines | Typical noise levels for machines with no noise-reduction measures |

|---|---|

| Noise level dB(A) | |

| Lathes | 80 |

| Beam panel saws and sanding machines | 97 |

| Boring machines | 98 |

| Band re-saws, panel planers and vertical spindle moulders | 100 |

| Portable woodworking tools | 101 |

| Bench saws and multiple rip saws | 102 |

| High-speed routers and moulders | 103 |

| Thicknessers | 104 |

| Edge banders and multicutter moulding machines | 105 |

| Double-end tenoners | 107 |

Factors that can increase noise levels when using woodworking machines:

- using dry, hard, stiff timbers

- size of the work piece (longer, thinner or wider pieces vibrate more and carry noise)

- machines with dull knives and worn blades and bands

- higher tool speeds

- out-of-balance tools

- machine settings that do not adequately control and support the timber. The freer the timber is to vibrate the greater the noise level

- lack of damping or no sound enclosure around the machine

Noise and the law

Under the Work Health and Safety Act 2011 and the Work Health and Safety Regulation 2017, businesses are required to manage the risks of hearing loss associated with noise at the workplace. You need to:

- make sure the noise a worker is exposed to at the workplace does not exceed standard noise levels

- provide audiometric testing to workers who use personal hearing protectors and are frequently exposed to noise that exceeds the exposure standard

What you need to do

1. Check to see if you have a noise problem at your workplace

Ask yourself these questions:

- do people need to raise their voice in order to communicate with someone about one metre away?

- do people notice a reduction in hearing over the course of a day?

- do workers ask you to repeat things already said?

- do workers experience any of the following:

- ringing in the ears (tinnitus)?

- the same sound having a different tone in each ear?

- muffled hearing?

- are any of your long-term workers hard of hearing?

- do any workers operate noisy machinery for long periods?

If you answered ‘yes’ to any of the above questions, the chances are that your workplace could be putting workers’ hearing at risk. You can also use a hand-held integrated sound level meter to measure noise levels.

2. Manage the noise levels

If your workers are at risk, you need to fix the problem.

- Identify the sources of noise in your workplace. Regularly walk around the workplace and talk to your workers. Find out where the noise is coming from, and what machines and work tasks produce high levels of noise

- Assess the risk and effect on workers and people near the noise areas

- Remove the cause of the noise eg get rid of noisy machinery, outsource noisy work

- Reduce the noise – if you can’t remove the noise, then you need to control it:

- buy and use quieter machines and tools with low-noise blades

- install anti-vibration mountings

- fit silencers to reduce the noise of compressed air exhausts and blowing nozzles

- regularly maintain the machinery

- move loud exhaust or extraction units outside

- put enclosures around noisy machines

- fit damping materials (such as rubber) or stiffening to panels to reduce vibration

- use barriers and screens to block the noise

- turn down the volume controls on machines

- change the speeds of machines

- use remote controls to operate noisy machines from a distance

- Protect workers by changing the way the work is done:

- make sure that noisy work is done when only a few workers are present

- limit the time workers spend in noisy areas by changing work rosters to move them around, or moving them to quieter areas

- put noise warning signs up in the workplace to make workers and people aware of noisy areas and machine

- provide quiet areas for rest breaks for workers that are exposed to noisy work

- where needed, provide workers with personal hearing protectors that are the right size and fit, and are comfortable to wear. Make sure the equipment is regularly maintained, repaired and replaced so it continues to reduce the noise and risk of hearing loss

- attach warning signs to tools and equipment to advise workers that personal hearing protectors must be worn when using them

- make sure workers have regular hearing checks if they are working in areas that exceed standard noise levels and require them to wear personal hearing protection

- make sure your workers are correctly trained and supervised when working in noisy areas and with noisy machines and equipment

3. Review the noise levels

Regularly check to see if these controls are working and if you need to take further action to remove or reduce the noise. Talk to your workers about noise hazards and controls.

For more information

Refer to the Safework NSW Code of practice: managing noise and preventing hearing loss at work 2011. Call 13 10 50.

SW08418 0816