Blogs

Safety Governance Awards

Consider nominating your workplace for the first ever Safety Governance Awards, proudly sponsored by SafeWork NSW.

These national awards aim to recognise organisations that go beyond frontline management of risks and hazards, to set up effective oversight of workplace safety by boards and executives.

This can include things like:

- setting up whistle blower hotlines so workers can anonymously report hazards

- making sure boards have access to independent advice

- offering ongoing education to leaders so they can protect the safety of their workplace, products, services and clients.

Awards are available in nine categories

- Excellence in safety governance – leadership and culture

- Safety, risk, governance or sustainability committees

- Board recruitment, review and remuneration

- Board and leaders education

- WHS governance reporting

- WHS governance auditing and advising

- Whistle blower programmes

- Supply chain and modern slavery

- Response to significant event

Nominate your organisation

Submit your nomination on the Safety Governance Foundation website

Nominations close 16 April 2023.

The winners will be announced on 17 May 2023.

National WHS Radar

The Centre for Work Health and Safety has launched the National WHS Radar, an initiative that will deliver the latest insights on work health and safety in Australian workplaces twice a year.

The National WHS Radar will empower Australian regulators, academics, and leaders to take a proactive approach to WHS, informing existing and future policies, practices, and research projects.

How can you get involved?

The first round of the National WHS Radar survey will be released on Monday 9 January 2023 and will be open until Tuesday 31 January 2023.

Take the survey now and go in the draw to win a $500 gift card.

We encourage you to share the survey with your network so we gather as many experiences from Australian workers as possible.

How does it work?

Every six months, the Centre’s Research Team will delve into a range of new WHS data and evidence.

The team will incorporate data from these five streams:

- existing data, including incidents, worker’s compensation, ABS, and prosecutions

- analysis of grey literature

- social media listening

- nationwide survey of WHS inspectors and experts

- nationwide survey of Australian workers across all industries

The Team will then analyse and synthesise this information into reports that will be made publicly available.

What’s the benefit?

This type of reporting has never been done at this scale and frequency in Australia.

The National WHS Radar Reports will deliver relevant, local, and current information into the hands of the people who can effect real change, and ultimately create safer workplaces in Australia.

Where can I read the reports?

The National WHS Radar Reports will be shared on the Centre's website and other communication channels.

The first report will be released in April 2023.

If you would like updates on the reports, head to the Centre's Engage with us page.

Make safety a priority this festive season

With the festive season fast approaching there is a flurry of activity in workplaces.

Whether you have just picked up a summer gig, or rushing to finish jobs before the holidays, make sure your safety is top of mind.

It is easy to forget work health and safety basics when you're distracted, stressed or winding down.

Resources to help

October is National Safe Work Month

National Safe Work Month is a time to commit to building safe and healthy workplaces and this October, SafeWork NSW is sending a strong reminder that health and safety is an everyday priority.

This year’s National Safe Work month theme is "safety: every job, every day" encouraging all workplaces to prioritise safety, every day.

How to get involved

Host a SafeTea chat: SafeTea resources are available on the National Safe Work Month website, visit the Safe Work Australia website. Find information on SafeWork NSW events.

To view the current SafeWork NSW campaign visit Safe at work. There for them.

Regional roadshow: Managing psychosocial hazards in the workplace

SafeWork Inspectors will deliver free face-to-face information sessions about managing psychosocial hazards in the workplace in 10 regional areas.

Psychosocial hazards at work can cause workers harm, disrupt workplaces, and cost time and money. Common psychosocial hazards include fatigue, high workloads, workplace violence, bullying and sexual harassment.

Since 2015, there has been a 53% increase in claims for psychological injury across NSW and the average cost of these is more than $85,000 per claim.*

On 1 October 2022, new laws will come into force about managing psychosocial risks in the workplace.

To help businesses in regional areas understand more about psychosocial hazards, SafeWork Inspectors will hold free face-to-face information sessions as part of a regional roadshow.

Read more and register on Eventbrite

Who is eligible to attend?

The information sessions are open to people from any industry in NSW.

Small business owners (less than 50 employees) will be eligible to claim the $1,000 SafeWork small business rebate after attending the training.

Professional development points are also available to trade industry workers.

What will you learn?

Each face-to-face session will cover the following topics:

- the Code of practice on managing psychosocial hazards at work

- real examples of psychosocial hazards

- strategies and free tools to help identify, assess and manage psychosocial hazards

- the new Mentally Healthy Workplaces regional resource kit, a new resource that provides practical actions that address common issues impacting regional businesses.

What sessions are available?

Below is the timetable for the regional roadshow. The sessions are free and two hours in duration. Registration is required.

Albury, Tuesday 18 October, 10.00am - 12.00pm

Coffs Harbour, Thursday 24 November, 10.00am - 12.00pm

Dubbo, Tuesday 25 October, 10.00am - 12.00pm

Newcastle, Thursday 17 November, 11.00am - 1.00pm

Nowra, Wednesday 26 October, 3.00pm - 5.00pm

Orange, Thursday 27 October, 10.00am - 12.00pm

Port Macquarie, Tuesday 29 November, 2.00pm - 4.00pm

Tamworth, Tuesday 15 November, 4.30pm - 6.30pm

Wagga Wagga, Thursday 20 October, 10.00am - 12.00pm

Wollongong, Tuesday 25 October, 10.00am - 12.00pm

* SafeWork NSW public consultation on the code of practice for managing the risks to psychological health, September 2020.

2021 SafeWork Awards winners have been announced

The annual awards ceremony on Wednesday 27 October 2021 recognised businesses and individuals for excellence in work health and safety. This year, the two categories recognised businesses, industry associations and unions who have protected workers at risk.

There were eight winners of the 2021 SafeWork Awards:

Businesses

- Talk 5 Pty Ltd

- Gymnastics NSW

- Koppers Wood Products Pty Ltd

- IPAR Rehabilitation

- Prescribe Australia

- UGL Unipart

Industry associations and unions

- NSW State Emergency Service

- Australian Services Union NSW & ACT (Services) Branch, and,

- Master Builders Association of NSW.

Four finalists received the highly commended award: Carter Heavy Haulage & Transport Pty Ltd, Gutter Monkeys Pty Ltd, The Big Banana Pty Ltd, Essential Energy.

To hear a little more about our winners and their solutions, head to the SafeWork NSW YouTube channel.

Working safely at heights in construction

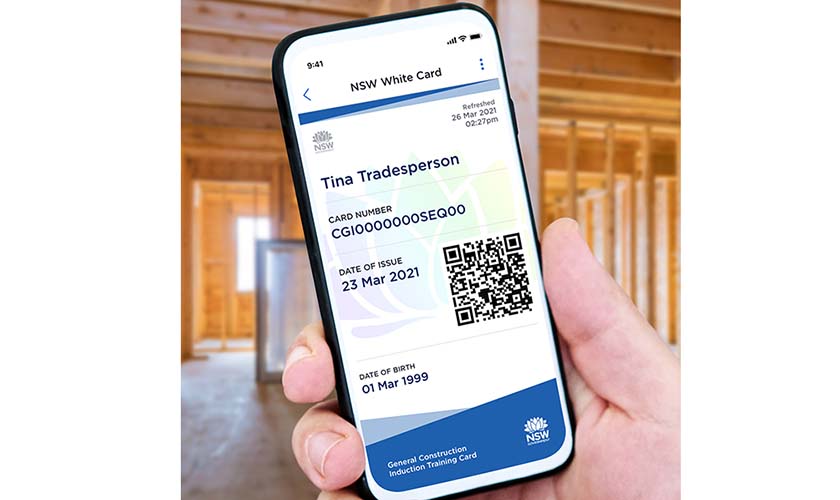

Digital White Card now available

Service NSW, along with SafeWork NSW, has rolled out the first Digital Trade Licence. Now, you can get the SafeWork NSW Digital ‘White Card’ for general construction induction.

The Digital White Card offers a digital option for customers who prefer it. However, you may be required to produce your physical white card.

To obtain:

- download the Service NSW app on your phone. If you already have the app, update to the latest version

- log in to the Service NSW app with your MyServiceNSW Account details

- select 'Wallet' from the homescreen and then the 'Add' button. followed by ‘White Card’ and enter your credentials

- read the terms and conditions and click ‘I Accept.’

Your Digital White Card will then be prepared and displayed.

Learn more about the Digital trade licence program.

Apply for your Digital White Card on the Service NSW website or call 13 77 88.

Speak up to report a work health and safety concern

Speaking up about an unsafe work environment can feel like a challenge, especially if you are a younger worker or if English is not your first language. Sometimes you may feel you don’t have a voice.

It’s important to understand that people can be seriously injured or killed when work health and safety issues are not raised in the workplace.

It’s everyone’s responsibility to raise hazardous working environments to a manager or supervisor, however if you don’t feel comfortable or aren’t able to speak up at work; you can tell us via the Speak Up Save Lives app.

The Speak Up Save Lives app is an effective tool to anonymously report any health and safety concerns you may have in your workplace.

All submissions via Speak Up Safe Lives app are assessed and responded to by SafeWork NSW. You’ll also get a reference number so you can follow up, should you wish to share your details.

If you choose to share your contact details, we can keep you updated on the outcome of your submission. We can also advise you on how to manage the safety issue, including how to raise it with your employer or supervisor. We can also let you know what the law says about your concern.

If your submission identifies a potentially serious safety issue, we may need to send an inspector out to the workplace.

If there is an incident involving a serious injury or illness of a person, a death of a person or a potentially dangerous incident, the person in charge will need to notify SafeWork NSW immediately by calling 13 10 50.

Or you can report an incident online.

Drought assistance

As NSW experiences one of the worst droughts on record, the NSW Government is offering a range of relief measures to support impacted farmers and communities.

As part of these initiatives, we will waive licence fees to drought affected customers from 1 October, who are experiencing financial hardship.

To be eligible you must work or live in an area classified as “Intense Drought or Drought” by the Department of Primary Industries.

To see if you qualify for your fees to be waived contact us on 131 050.

You may also be eligible for other assistance. See:

Paralympian Speaker Program

There is a group of safety champions whose job it is to look you in the eye and tell you it is important.

The icare Paralympian Speaker Program really is a unique way to raise awareness of workplace health and safety.

It's run in partnership with Paralympics Australia and provides icare customers with free access to current and former Paralympians who sustained their disability through a work-related injury.

They're the sort of people you respect, not just because they overcame serious, debilitating work-related injuries themselves, but because they soared above their injuries, going on to master a sport and then share their stories to make other workplaces better and safer.

Since 2000, the program has made it possible for Paralympian speakers to leverage their own injuries to connect with workers and employers across industries in the belief that they can change lives.

In this period of time, we imagine they've changed a vast number and saved more than a few.

There is power in stories - if your safety messages seem to be falling on deaf ears, why not try a different approach and invite a Paralympian speaker to talk to your workers?

Step by step information service for life events

At SafeWork NSW, we have an online toolkit that helps you create a safer, healthier and more successful business.

The NSW Government has also produced a range of online guides to help you during life’s many complex events.

Whether you’re starting a family or planning for retirement; starting school or getting your first job; suffering a serious injury or planning a funeral; renting property or dealing with a flood, these guides will improve your access to the many services the government can offer you during the significant events in your life.

Information, advice and support so that you can make the right decisions for you.

Putting you at the centre of everything we do is one of the Premier’s priorities.

Beware – working when young

During the January to March 2019 quarter, we prosecuted eight companies in the district or local courts for breaching work health and safety laws.

In all these cases employers were fined for tragedies that could have easily been avoided.

In four cases, young workers were seriously injured and one young worker died.

A 25 year old male sustained serious injuries when he and his co-worker fell 11 storeys from a 12 storey building while cleaning the outside windows. The ropes failed on the exterior maintenance platform they were working on. As a result, the business was fined $300,000 for neglecting to maintain their equipment.

Another 25 year old male sustained fatal head injuries when he fell from his motorbike while mustering sheep on a farm north east of Broken Hill. He was not wearing a helmet.

Two more young workers were critically injured in incidents while cleaning in commercial kitchens. A 17 year old male suffered third degree burns to both his feet and subsequently spent seven weeks in hospital while mopping up hazardous chemicals at a Queanbeyan hotel.

A 24 year old male slipped and stepped into a pot of hot cooking oil when he was cleaning the canopies of a commercial cooking unit. He also sustained third degree burns up to his knee and required skin grafts.

Tony Williams, SafeWork NSW Executive Director of Operations said regardless of how a young worker is employed or in which industry, they require extra support to ensure they are carrying out their tasks correctly and safely.

“We know young workers are less likely to speak up, they don’t have the experience and they are often employed in more casual or temporary positions, all of which makes them more vulnerable to hazards,” Mr Williams said.

“If you are a young worker you need to know your rights and understand that your employer has obligations to ensure your workplace is safe and you are trained for your job.”

All workers have the right to:

- be shown how to work safely

- appropriate safety equipment

- speak up

- say no to unsafe work

- be consulted

- workers compensation

- a fair and just workplace

- fair pay and conditions.

You have obligations too, such as taking reasonable care of yourself, not doing anything that would affect the health and safety of others at work and following any reasonable health and safety instructions from your employer.

“If you are an employer or supervisor it is critical that you encourage all young workers to speak up when they are not sure how to do a job or don’t feel that a job they are doing is as safe as it could be,” said Mr Williams.

“This will be something they can then carry through their working lives that will help keep themselves and others safe.”

Our Young Workers e-Toolkit for employers and young workers has a range of resources including how to deal with difficult scenarios and steps for assessing a situation – wait, take five.

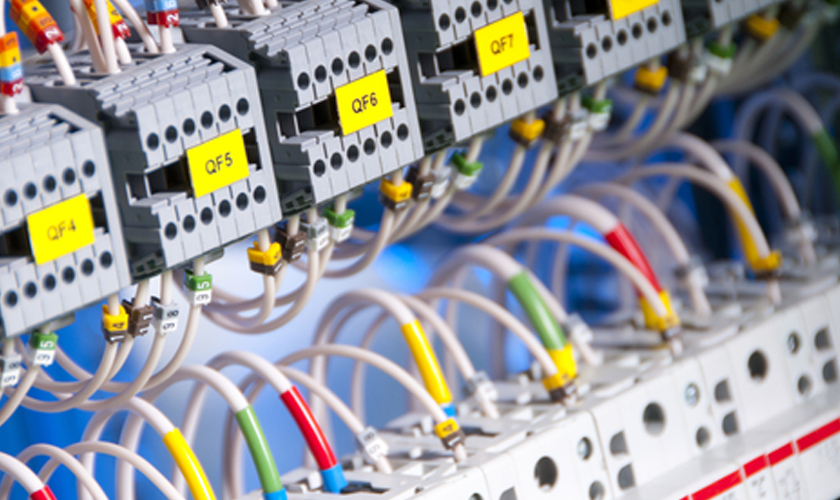

Getting back to work after injury

Finding suitable duties for an injured worker in the construction industry can often hit a brick wall.

While most workers recover faster at work than at home, this concept can be a stumbling block for many construction employers.

‘Construction is a very physically demanding industry and one where small employers will often feel that a recovering at work after an incident is impossible,’ SafeWork NSW inspector Lydia Grepl said.

‘But we have numerous examples that show a staged return to work is actually possible in many cases.’

One involved a 22-year-old qualified electrician who sustained life-threatening head injuries requiring lengthy recovery after falling three metres at a Sydney residential construction site.

It is believed that the electrician fell head-first through the stair void on the first level where there was no handrail, platform or barrier installed.

‘This worker was very lucky to survive,’ the inspector said.

‘He had to re-learn basic human skills such as how to talk, walk, write and eat.’

Remarkably, eight months later the worker had recovered enough to begin a staged return to work on suitable duties, supported by his employer, insurer and doctor.

Initially assembling switchboards for four hours a day, two days per week in a warehouse, this increased by an extra day within a month, then an additional two hours a day. Soon, he was working eight hours a day, three days a week, and visiting sites to fit power points and conduct maintenance work. This gave him great relief and improved both his physical and mental wellbeing as he was able to return to some sense of normal after his incident.

‘This was a good example of how a successful staged return to work can be achieved in the construction industry.’

Find out how to develop a return to work program.

Protecting workers from the risk of falls

These fines can be issued by inspectors if the risk to workers is imminent or serious, or if the workplace is considered to be a repeat offender.

The fines are aimed at reducing the number of worker fatalities and serious injuries, and protecting workers and the community from these high-risk activities.

In 2017 alone, we attended 234 incidents involving falls from heights. Over half these incidents occurred in the construction industry.

Eight workers were killed in NSW in 2017, as a result of a fall from height.

Working at heights is a high-risk work activity and requires a safe work method statement. You must assess the risks involved for each activity that involves working at height, and implement the highest level of control that is reasonably practical in the circumstances.

You can:

- use a suitable working platform and, wherever possible, undertake the work from the ground

- use edge protection, such as scaffolding or guardrails ensure all scaffolds are checked by a competent person and handover certificate is provided before using

securely cover open penetrations, or use physical barriers - have a safe means of access and egress to all relevant areas of the worksite only use fall restraints and fall arrest systems when other higher order controls are not reasonably practicable

- establish and test emergency procedures for fall restraint/arrest systems

- only use ladders for access and egress, or for short term work when controls such as working platforms and scaffolds are not practical

- give your workers relevant equipment, information, training and instruction to work safely at heights.

Fines are $720 for an individual and $3600 for a corporation.

See how simple safety can be when you’re working at heights.

Good consultation improving more than just the bottom line

But for Groves Joinery owners Tracey and Gary Fuss, the reasons for putting good workplace consultation methods in place aren’t just about the bottom line – they’re much closer to home.

“Our employees have become an extension of our family, so it’s vital that we keep them safe,” said Tracey, who has owned the small joinery business with her husband Gary for 11 years.

“It’s our responsibility to make sure they are equipped with all of the information they need to make sure that their safety is protected on a daily basis. Continually talking and consulting with them about safety is the best way to do this.”

Groves Joinery mainly manufactures kitchens for the Hunter region. The business employs eight workers and two subcontractors. The main risks within their workplace revolve around working with machinery, manual handling, and completing repetitive tasks that can cause strain.

Tracey said their simple, but effective workplace consultation methods have created a culture in the business whereby safety is second nature.

“We don’t use the term consultation because I feel that is one of the terms that make people feel like it’s a long and possibly complex process. I probably use the words ‘a chat about safety’,” Tracey said.

“We like to do it in a non-formal setting for the most part. For us, consultation is an open discussion regarding a safety issue and working through the best way for the whole business to manage it.”

The staff at Groves Joinery participate in regular monthly meetings where they are encouraged to raise and talk through safety matters. Issues are identified and documented, and solutions are then implemented.

Tracey also relies heavily on the experience of her workers to help inform workplace procedures and policies.

“They’re at the coalface, so it’s important that we listen to what they have to say, and they’re really good at feeding back information about things we can do to improve, or changes that we can make to be safer.”

This extends further than just talking about safety, with Tracey and Gary also using consultation methods to plan for the future of their business.

For example, when deciding on new machinery or equipment, Gary talks with his workers at the business to help make decisions about what to buy.

When that new machinery is installed, the workers all stop work to go through the operating procedures for the machinery, and to talk about risks and how to prevent them while using it.

“It doesn’t have to be formal, and the bulk of what we do isn’t formal. But it’s these simple things that have made a big difference for us,” Tracey said.

Although Tracey had had some experience in work health and safety in her previous job as a registered nurse, she admits to feeling slightly overwhelmed when starting to review the consultation methods in her own business.

“I think the most important thing is to just make a start. Just start with one thing. I started with our general WHS policy and just built from there,” she said.

“It’s all about looking at those things – the bigger picture. So my advice to other businesses would be to write yourself a list and just start.”

Let SafeWork NSW help you implement effective workplace consultation methods in your workplace. Request a free safety advisory visit or call 13 10 50.

Help us shape the future of mental health in small business

With 1.51 million people working in small business in NSW, approximately 600,000 may be affected each year.

The opportunity to change the mental health and wellbeing of the NSW community by targeting small business is great.

Despite the availability of effective treatments for mental health conditions, evidence suggests that many people either do not seek treatment at all, or seek treatment following lengthy delays, during which the health, social and work consequences can accumulate.

Evidence also suggests that current workplace mental health programs tend to focus on larger organisations and industries and are not addressing the unique nature or the specific needs of small business.

Researchers at Everymind are developing a workplace mental health program for those who work in small business. They will work in partnership with the Priority Research Centre for Brain and Mental Health Research at the University of Newcastle, the icare Foundation, and other health, mental health and business partners in NSW and nationally.

If you own a small business or have worked in a small business (20 employees or less), tell us what you think about mental health!

A range of mental health resources are also available from our website or call 13 10 50.

Hazardous chemicals: from mushroom farms to stonemasons

Eight people died and more than 250 are now permanently disabled.

These fatalities and injuries are 100 per cent preventable when the workplace is safe and the simplest of control measures are used, like ventilators, respirators, gloves and goggles.

After consultation and negotiation with key stakeholders, we have identified the top 10 ‘priority chemicals’ used in NSW workplaces.

Over the next five years, inspectors will contact more than 10,000 workplaces to help businesses use these chemicals safely.

Initially, the focus will be on the top two chemicals – formaldehyde and crystalline silica – which can cause anything from allergic skin reactions to lung disease.

Inspectors will visit workplaces where formaldehyde is likely to be found, such as hospitals, laboratories, manufacturers of wood-pressed products (such as MDF board), poultry and mushroom farms, and funeral homes.

They will also visit workplaces where crystalline silica is present, workplaces where tunnels and roads are constructed, as well as stonemasons and manufacturers of polished stone benches.

A New South Wales parliamentary inquiry into the Dust Diseases Scheme was told that silicosis had become a huge problem in the manufactured stone industry, particularly in small businesses.

For crystalline silica workplaces, air monitoring records will be reviewed to ensure that workers are working below the limits required by the Australian Workplace Exposure Standard and that health monitoring is being undertaken.

And we will work closely with SafeWork Australia to review these standards, to ensure they meet international best practice exposure limits for crystalline silica.

We will also review current health monitoring tests, to ensure they are still the most adequate tests available for the early detection of any changes to health.

We will work in collaboration with iCare and Dust Diseases Care to make the lung bus available in regional areas and large workplaces for health monitoring tests, and will work with other government agencies and stakeholders to influence the introduction of a mandatory reporting program for occupational respiratory diseases.

By 2022, not only will serious injuries and illnesses have fallen by 30 per cent, but NSW businesses will have implemented best practice controls to eliminate or significantly reduce hazardous chemical exposures in their workplaces and exposure standards will be in line with international best practice.

Also, the testing of silicosis will be the most accurate and efficient available worldwide, a respiratory disease register will hopefully be legislated, and at-risk workers will receive and understand key safety messaging.

Managing musculoskeletal disorder

Every year, we see over 19,000 major musculoskeletal disorder (MSD) claims costing on average over $30,000 per claim.

In 2016, we launched a six-year work health and safety strategy that set a target of reducing serious MSDs. We met an exceeded the original target of 30 per cent. The target is now set at 50 per cent.

Following consultation with a variety of industry sectors, we subsequently developed and launched an MSD strategy that focuses on those at greatest risk, such as storepersons and nurses.

If we can meet this 50 per cent target, it will see thousands fewer workers receiving a serious MSD, saving NSW businesses in excess of $415 million.

The strategy highlights the impact that MSDs have in the workplace and identifies approaches to reduce their incidence and severity.

Consultation and communication are the foundation for the effective management of MSDs.

The essential ingredients for successfully managing MSDs in the workplace include embedding a work health and safety landscape to address risks that lead to MSDs; eliminating MSD hazards at the planning, purchasing and design stage; increasing the use of high level controls; ensuring effective reporting and compliance with legal responsibilities; and supporting injured workers to recover at work.

As an ideal starting point, we recommend the PErforM program– Participative Ergonomics for Manual Tasks. It is a simple, internationally recommended program that helps to effectively manage hazardous manual tasks.

Get more information on the PErforM program and check out the free PErforM workshop schedule.

When small wins = big change

It’s not unusual for people to be averse to change. It can challenge us and make us feel uncomfortable, particularly when we’ve had the same habit for years. Change at work can be equally confronting.

But according to Marco Rindo, Work Health Safety and Compliance Manager at Carey’s Freight Lines, celebrating the small wins is the best way to get people on board.

“Safety can be a hard sell,” said Marco.

“Some people have been in our team for 20 or 30 years and change can be overwhelming.

“I’ve worked at Carey’s Freight Lines for five years now and have come to realise that small wins matter.

“By showing the positive outcome of the change you actually see increased engagement from workers.

“They want to become part of that change.”

Carey’s Freight Lines is a family owned company established in 1927.

It manages refrigerated freight, general freight and container transport across Brisbane, Sydney and Tamworth.

Four years ago, they implemented a consultation process, led by Marco, to manage the risks faced by their workers.

“It was a bit difficult at first to get support from all 120 workers, but Australia’s views on wellbeing at work are changing, which has created a big shift over the past four years,” said Marco.

Marco believes the trick is to show the small improvements, and to be transparent and honest with workers throughout the process.

He is now starting to see a different attitude emerge among workers .

“We recently installed electronic work diaries (EWDs) into our trucks to track driver’s hours,” Marco said.

“The EWDs allow us to monitor how long a driver has been working, and then send alerts to the driver and office staff when they need to take a break or stop working.

“They were hesitant at first, but now some won’t get in the truck without them.

“They know the EWDs are there to assist with our chain of responsibility obligations, keep them safe, and make sure they come home to their families.

“It was a big change, so we took it slow by installing the EWDs in a select few trucks.

“We listened to feedback from the drivers, sent our insights to workers via our newsletter and discussed them during consultation meetings.”

The EWDs are just one safety change Carey’s Freight Lines have undertaken over the years. Other changes have been smaller, but all contribute to the larger goal of improving the mental and physical health and wellbeing of their workers.

“We have a number of monthly meetings for different facets of the business with the first agenda item always being safety.

“Meeting minutes and newsletters are made accessible to all workers through our noticeboards, via email and uploaded to the trucks on board ‘iFace’.

“Our monthly newsletter has a dedicated section to health and safety.

“It keeps everyone up-to-date on the latest initiatives and gives us the opportunity to celebrate the little wins across departments.”

A strategy for workplace mental health

Workers sitting around a table chatting.

The scientific, professional and technical sectors were the worst performing industries.

It is estimated that the cost of mental health issues to NSW employers is about $2.8 million a year. Research also suggests that businesses that invest in workplace mental health programs could reap more than $4 for every $1 invested as a result of improvements to productivity and reductions in absenteeism.

Mental illness is now the leading cause of long-term sickness among Australian workers, overtaking back pain as the most common cause of work incapacity.

Our six-year Work Health and Safety Roadmap includes a commitment to reduce serious injuries and illnesses by 30 per cent by 2022, with a focus on serious mental health disorders. Please note, the Roadmap has been replaced by the SafeWork NSW Regulatory Priorities 2023.

A Mentally Healthy Strategy of NSW incorporating initiatives designed to raise awareness and improve business capability to prevent and manage poor mental health in the workplace will be developed in consultation with stakeholders, along with

a range of compliance and enforcement measures.

In this short video, Sam Harvey, Associate Professor at the University of NSW and Professor Nick Glozier from the University of Sydney share their thoughts on the importance of creating a mentally healthy workplace.

How to report a serious incident

Not only is telling us about work-related ‘notifiable incidents’ a legal requirement, but it can help us pinpoint causes and take action to prevent similar incidents. A ‘notifiable incident’ is a death, serious injury, illness or dangerous incident.

Commonly referred to as a ‘near miss’, a dangerous incident is reportable if it exposes someone to a serious health and safety threat.

A serious incident, meanwhile, is any work-related fatality or serious injury or illness and must be reported immediately, whether it involves a worker, contractor or member of the public.

In the aftermath of a serious incident, there is often confusion and people in shock but it is important that the incident scene is preserved intact – other than treating or rescuing an injured person and making the immediate area safe – until an inspector arrives or tells you otherwise.

The list of potential injuries or illnesses that qualify as serious is lengthy but a rule of thumb is any injury or condition that requires immediate professional medical treatment and admission to hospital as an in-patient.

It’s crucial no time is lost. Call us on 13 10 50. If outside normal business hours, calls are diverted to a special after-hours emergency service.

Provide a clear and detailed description of the incident to help us assess if it is notifiable. It’s possible you may be asked to submit follow-up details in writing, but you will have 48 hours to do so.

Start with a brief summary of what happened and whether it was a death, serious injury or dangerous incident, and the date and time it occurred. Establish where exactly the incident happened and, for example, what equipment, machinery or structures were involved.

Next, provide a fuller description of the incident along with the injured person’s name, date of birth, address, contact number, occupation and role within the business – and details about the business or businesses involved.

Describe the injury or illness, initial treatment and where the person has been taken for medical attention, and if any action has been taken or is planned to prevent similar incidents. You must also keep a record of the incident for at least five years.

Penalties apply for not notifying incidents. M S Glass Pty Limited failed to immediately notify SafeWork of an incident after a worker was injured. After our investigation, the local court convicted and fined MS Glass Pty Ltd $4,000. The maximum penalty for failing to notify is $50,000 for a body corporate and $10,000 for an individual.

For more information, see our customer service standard.

Centre for Work Health and Safety

The Centre for Work Health and Safety is looking to the road ahead

Comprising experts in the fields of research, insights and analytics, science outreach and business, the Centre leverages data and evidence to create awareness, suggest smarter approaches and bring about behaviour change in work health and safety.

The team doesn’t do this alone – a key approach of the Centre is co-designing its research with industry, workers, government, academia and regulators to uncover insights that:

- ensure the research is practical and useful for the end user

generate and disseminate new knowledge about work health and safety risks and controls - quickly translate research findings and knowledge into practice and innovative harm prevention interventions

- identify, pose and tackle important questions around current and emerging work health and safety risks.

Since its launch, the Centre has been hard at work defining its research focus. The Centre is working towards its Research Blueprint, which spells out its research strategy to 2022. This strategy is aligned to the targets and priority areas identified in the Work Health and Safety Roadmap for NSW 2022. (Please note, the Roadmap has been replaced by the SafeWork NSW Regulatory Priorities 2023).

The Centre has also started its first round of research projects. These include looking at effective engagement between workers, industry and regulators; what work health means to NSW workers; and drawing on evidence to inform best practice regulation.

For more information visit the Centre for Work Health and Safety website or join the conversation on social media @centreforWHS.

Enviable health and safety landscapes

Sailfish Catamaran

Established in 1993 and based in Alstonville in northern NSW, Sailfish Catamarans builds aluminium boats. From a staff of two producing five boats a year, the company has grown to a staff of 19 full time tradesmen and apprentices building about 30 custom-built catamarans a year. Today, it is a successful manufacturing and exporting business.

It is also the envy of many small businesses, having won the 2017 SafeWork award for excellence in workplace health and safety culture for small business.

‘It’s a great achievement,’ said Ian Drew, Purchasing and Administration Officer.

‘We’ve come a long way and everyone’s on board with our new culture.’

The company is proud of its young workforce and employs a new apprentice every year – and from day 1 a safety culture is embedded. New employees are taught the company’s values, what they will learn, work ethic and workplace expectations.

This, coupled with a no bullying policy and apprentice buddy system, allows everyone to understand and own their responsibilities in the workplace.

The owner, Darren Foster, says the company has undergone significant cultural change in its commitment to health and safety. There is now an open door policy with all senior management regarding health and safety issues, and daily tool box talks in which all mangers participate.

The company’s consultation process recently resulted in new equipment being introduced to address risks associated with working at heights.

Today, Sailfish Catamarans boasts a dynamic workforce that is committed to safety.

Port Stephens Council

Testament to Port Stephens Council’s outstanding safety culture is a work health and safety audit score exceeding other regional councils by more than 20 per cent.

The council is also the winner of the 2017 SafeWork award for excellence in workplace health and safety culture for large business.

The council boasts 13 health and safety representatives, plus deputies, a hazard ID app, a dedicated safety page on its intranet, health and safety noticeboards, ergonomic assessments, safety alerts, monthly newsletters, and a health and wellness program.

The general manager attends induction sessions for new employees and chairs health and safety committee meetings, and all senior managers are required to do two field visits every month.

The results speak for themselves: premiums are down 50 per cent over the past seven years; cost of claims are about half that of other councils; the number of claims have fallen almost 50 per cent over the past six years; and the council scored over 96 per cent in a work health and safety audit, compared with about 75 per cent for other councils.

Read more about the SafeWork NSW Awards.

30 years' bad practice bites back

NSW District Court Judge David Russell fined the business owner $60,000 for breaching his health and safety duties regarding safe systems of work and $1,500 for failing to notify us of a serious incident immediately after becoming aware of it.

The principal duties of the worker included making houseboats and doing general steel fabrication work. He was a first-class sheet metal worker and held a forklift and elevated work platform licence, but had no formal qualifications as a roofer and no training in relation to working from heights.

On the day of the incident, the business owner left work early to attend a funeral and, during his absence, another worker – supposedly the company’s ‘informal’ supervisor (given he’d been with the company the longest) – told his colleague to finish roofing the workshop.

The worker used a scissor lift to access the roof and convey the cladding to the roof, then climbed out of the lift to secure the sheeting. When a sheet slipped sideways, the worker fell almost three metres onto a compressor and another metre onto a concrete floor. There was no fall prevention system in place.

Immediately following the fall, the supervisor called an ambulance then contacted the owner, who in turn notified the insurer (but not us). If there is a serious injury or illness, a death or a dangerous incident, the law says you must report it to us immediately – and notify your insurer within 48 hours.

Under cross examination, the business owner revealed that for the past 30 years workers’ regularly worked on houseboats and were often four metres above the ground without fall protection or proper training. This revelation was a clear contradiction to his assurance that had he been present at work, he would have insisted on getting a qualified roofing contractor and would have forbidden anyone else from doing the job.

See our Working at heights page for further information on minimising risk.

Best Individual Contribution to Workplace Health and Safety (WHS manager) winner

Glenn joined Calvary, a non-for-profit health organisation, in 2011. With more than 12,000 staff and volunteers, Calvary operates 15 public and private hospitals, 15 retirement and aged care facilities, and a national network of community care centres.

No sooner had he joined Calvary, Glenn set out to develop a group workplace health and safety strategy from the ground up – there was no safety system in place. A significant challenge was the geographical spread of the organisation, so he developed an intranet site that provided a single platform for all health and safety resources. He introduced online forums and discussion boards, audit tools, fact sheets, procedures and manuals.

Glenn also implemented a national safety excellence award program that recognised individuals and teams, a monthly safety scorecard, and a national management review process. He was particularly conscious of the need to engage with workers, health and safety representatives, committees and senior management.

Glenn’s initiatives have been a catalyst for other system and technological changes throughout the organisation. These same initiatives have also resulted in the frequency rate of lost time injuries falling from 60 to three since 2011.

An inspiration to us all

Twenty years ago, David was seriously injured when his arms became caught in a hay baler as he was trying to fix a fault. As the baler pulled his arms in with such force, he suffered chest and head injuries along with extensive injuries to both arms. He was trapped for more than an hour before being rescued by a passing motorist and rushed to hospital.

David spent five months in hospital, had his right arm amputated above the elbow and numerous surgeries to save the left arm, including orthopaedic reconstruction, skin grafting, vascular grafting and infection control.

David knew nothing other than farming and was widely known in his community for solving problems and finding solutions. And this horrific tragedy did not deter him. His motto: the farm will not beat me.

With the help of a rehabilitation provider, prosthetic technician, case manager, family and friends, he developed a comprehensive return to work program and purchased modified equipment through SIRA’s vocational rehabilitation program. He made changes to the farm set-up, re-designed his work practices, and researched widely to find equipment that would satisfy his needs.

David credits a determined, problem-solving attitude and a great team as the principal reasons for his remarkable achievements.

Although the incident happened 20 years ago, David continues to receive medical treatment for his injuries but has returned to his pre-injury duties as a self-employed cattle farmer, hay contractor, bob-cat operator and earth mover.

David’s achievements were recognised last year when he won the 2017 SafeWork NSW Award for Recovery at Work Achievement Award for Injured Workers.

Tech savvy consultation improves safety culture

We know that good workplace cultures improve employee mental health, increase productivity and boost workplace morale.

But how do you bond as a team if you don’t all work in the same place?

It’s a challenge faced by many NSW businesses who have mobile workers, operate across multiple states or rely on contractors.

The problem often falls on the shoulders of the HR or wellbeing manager to find an efficient way to coordinate the wellbeing of an organisation spread over multiple locations.

Retail construction company, Prime Build, faces this challenge everyday.

Technology therefore plays a big role for the team at Prime Build.

It allows all of their workers to remotely join in on conversations with the whole team and have their say.

Ronnie Boukaram, their WHSEQ Manager said staff work everywhere; in the office, on the road and throughout work sites across Australia.

“We work in a fast-paced, 24-hour environment,” Ronnie said.

“It can be exhausting and negatively impact our workers’ professional and personal lives if not managed properly.”

Ronnie got the ball rolling on new ways for people to connect and talk about safety and wellbeing.

“We have a Skype meeting once a month with the Prime Build Safety Team, which can be joined by anyone, to discuss all things safety related – including concerns, injuries and ideas for improvement.”

“We also have an online platform that enables employees to catch up on anything they missed, and a monthly newsletter that shares wins and upcoming projects.

The more connected we are, the better it is for morale.”

Ronnie is a firm believer in little changes making a big difference to overall workplace culture.

He saw how introducing a form for employee suggestions was pivotal in slowly improving processes throughout the company.

“It’s all about making small changes and constantly improving until you start seeing better outcomes.”

“Consultation doesn’t need to be an expensive or time-consuming process. Just listening to your team is a good first step to improving safety and culture.”

Managing Director, Dean Willemsen, emphasised that Prime Build’s consultation process was a constant learning process and encourages other workplaces to take it one step at a time.

“We are not perfect and have work to do,” Dean said.

“Here at Prime Build we are committed to continually improving and while we have made mistakes in the past, we are committed to learning from them.”

How we're tracking - at a glance

Since the release of the Work Health and Safety Roadmap 2018-2022, we’ve been working towards defined targets to reduce the number of fatalities, serious injuries and workplace illnesses. Please note, the Roadmap has been replaced by the SafeWork NSW Regulatory Priorities.

We’re keeping zero fatalities in our sights and tracking our progress on a range of safety fronts.

We want you to follow the numbers too, be involved in changing the safety landscape, and remain motivated to make NSW workplaces the safest places to work in the country.

Each quarter we will publish our status report so you can see how the Roadmap is influencing workplace safety in NSW.

An inspiration to us all

David Nugent owns a cattle farm near Wagga Wagga and does some contract work supplying hay and operating heavy machinery to supplement his income when times are tough.

Twenty years ago, David was seriously injured when his arms became caught in a hay baler as he was trying to fix a fault. As the baler pulled his arms in with such force, he suffered chest and head injuries along with extensive injuries to both arms. He was trapped for more than an hour before being rescued by a passing motorist and rushed to hospital.

David spent five months in hospital, had his right arm amputated above the elbow and numerous surgeries to save the left arm, including orthopaedic reconstruction, skin grafting, vascular grafting and infection control.

David knew nothing other than farming and was widely known in his community for solving problems and finding solutions. And this horrific tragedy did not deter him. His motto: the farm will not beat me.

With the help of a rehabilitation provider, prosthetic technician, case manager, family and friends, he developed a comprehensive return to work program and purchased modified equipment through SIRA’s vocational rehabilitation program. He made changes to the farm set-up, re-designed his work practices, and researched widely to find equipment that would satisfy his needs.

David credits a determined, problem-solving attitude and a great team as the principal reasons for his remarkable achievements.

Although the incident happened 20 years ago, David continues to receive medical treatment for his injuries but has returned to his pre-injury duties as a self-employed cattle farmer, hay contractor, bob-cat operator and earth mover.

David’s achievements were recognised last year when he won the 2017 SafeWork NSW Award for Recovery at Work Achievement Award for Injured Workers.

The best way to improve employees' mental health

A world-first study published in Lancet Psychiatry, led by researchers at the Black Dog Institute and University of NSW, suggests that basic mental health training for managers can result in significant benefits for employees.

The research looked at the effects of a four-hour mental health training program delivered to Fire & Rescue NSW managers.

It found that the training was associated with a return on investment of $9.98 for each dollar spent on training and major reductions in work-related sickness absence. It is also the first study to show that training managers about mental health can have a direct impact in improving occupational outcomes for workers.

‘Having a supportive manager can make a huge difference to a person’s mental wellbeing, and as this study shows, giving basic mental health training to managers can bring significant changes to both confidence and behaviour among staff,’ says Samuel Harvey, who leads the Workplace Mental Health Research Program at the Black Dog Institute.

Jason's story: A young life lost

In this video, produced by Workplace Health and Safety Queensland, Jason’s family and friends share their experiences to raise awareness about the importance of workplace safety, the need for effective communication between subcontractors on construction sites, and appropriate supervision and supportive mentoring for young workers.

It also brings to attention the importance of housekeeping in preventing incidents, and allowing emergency access to sites if an incident does occur.

Statistics show how vulnerable children and young people are in the workplace. They can be oblivious to hazards in their surroundings, are often unaware of their rights and responsibilities, and may not be confident to speak up about safety concerns.

On 28 April each year, countries around the world pause to commemorate workers who have died as a result of a workplace incident or occupational disease.

Each year, Unions NSW and SafeWork NSW hold a service on the 28th of April, which is International Day of Mourning to honour and remember those who lost their life at work.

At the service, families are invited to add ‘memory cards’ and flowers to the Memory Lines sculpture in honour of their loved ones.

We encourage employers and workers across the state to take time on International Day of Mourning to think about the significance of work health and safety and how workplace incidents can affect those around them.

For more information about young workers, read the Young Workers eToolkit which has information for parents, young workers and employers.

Managing hazardous chemicals

There are literally thousands of hazardous chemicals used in the workplace – paints, pesticides, cleaners and fuels, to name a few. They come in various forms – powders, solids, liquids and gases.

You must manage health and safety risks when storing, handling or using hazardous chemicals at a workplace by using the hierarchy of controls.

This video demonstrates what to consider when applying the hierarchy and how to go about choosing the appropriate controls.

You should review your chemical management strategies and use controls higher in the hierarchy in combination with lower level controls for the greatest effect.

You should also ensure that your workers receive training and supervision and consider the risks associated with storage, handling and disposal.

Through the implementation of the Hazardous chemicals and materials exposures baseline reduction strategy, the level and impact of workplace exposures to hazardous chemicals will be identified and reduced.

A priority list of 100 chemicals, based on national and international research has been developed, in which formaldehyde and crystalline silica rank first and second.

Read the codes of practice for more information on how to manage work health and safety risks and managing risks of hazardous chemicals in the workplace.

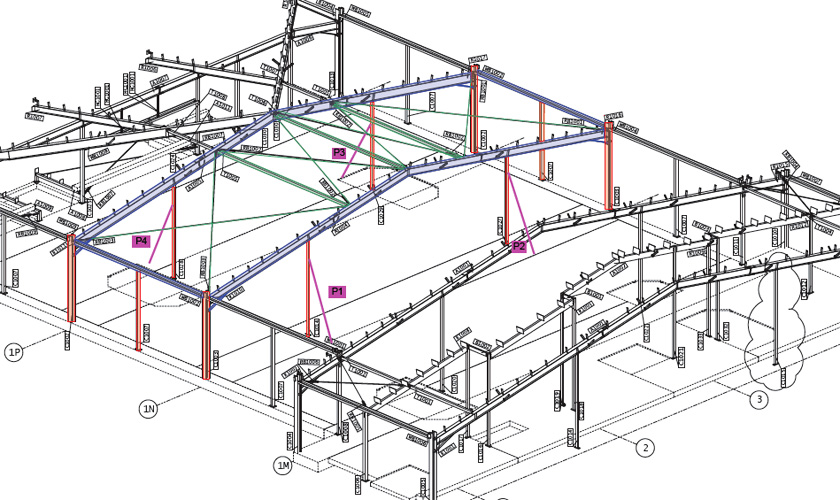

Safety improvements raising the bar

Following an incident where a worker sustained serious injury from being hit by a steel beam, Multiplex Constructions Pty Ltd (formerly Brookfield Multiplex Constructions Pty Ltd) agreed to undertake significant business safety improvements that would also benefit their industry and the wider community.

Headlining Multiplex’s achievements is their development of the Practical guide to the safe erection of steel structures, the principles of which have since been adopted as part of the Australian standard for structural steel fabrication and erection (AS/NZS 5131:2016). The guide was developed in consultation with the Australian Steel Institute, engineers and the construction workforce to bridge the gap between documented procedures and workplace practices.

Multiplex has also spent more than $100,000 on the evaluation and distribution of the guide across its organisation and the wider steel erection industry through the Australian Steel Association and the Australian Contractors Association. A training video summarising the detailed processes contained in the guide was also produced to help deliver safety awareness training for all workers and contractors in the steel erection industry.

Since the incident in January 2013, Multiplex has also spent over $50,000 on rectifications, which included developing a tool to conduct audits on structural steel erection work and updating their steel erection checklist.

Benefits to the community from the completion of the undertakings to SafeWork NSW include the funding of graduate scholarships at Wollongong and Newcastle University for work health and safety students.

Multiplex Constructions Pty Ltd continues to promote the use of the guide to improve safety practices to benefit both the industry and wider community.

Read more about enforceable undertakings.

Use power tools safely

Early this year, SafeWork inspectors attended an incident in southwest Sydney after a 15-year-old construction worker got severe lacerations to his thigh, down to the bone, while using a circular saw to cut lengths of timber. It was his first day on the job.

Power tools come in various shapes, sizes, voltages and varieties. Yet, irrespective of the size of the tool or how it’s powered, the principles of safe use apply equally to all.

First, remember that a power tool’s effectiveness is proportional to your level of training in using the tool, as well as your diligence in following safety guidelines.

Before starting any job, go through a pre-start process and ensure everyone who is using power tools is trained and competent. And always check to make sure tools are in good working order.

Keep your hands and feet away from moving parts, keep others a safe distance away, and wear the correct personal protective equipment for the job.

Finally, employers and experienced workers need to ensure new and young workers receive the correct training and supervision.

Watch the following video safety alert on how to keep you and your workers safe around power tools.

You can also watch this short video by the Roofing Tile Association of Australia. This video is relevant to all residential and commercial building constructors, and in particular, roof tilers.

Take a nap. Eat a snack.

Naps can help improve alertness. Many shift workers nap before and during their shift, and often before driving home in the morning.

Generally, when shift workers are sleepy, they turn to food for comfort. Tests have shown that those who eat a large meal during their night shift feel sleepier than those who don’t eat at all. The best advice is to eat a snack and avoid large meals.

Read the full article.

Use power tools safely

Power tools come in various shapes, sizes, voltages and varieties. Yet, irrespective of the size of the tool or how it’s powered, the principles of safe use apply equally to all.

First, remember that a power tool’s effectiveness is proportional to your level of training in using the tool, as well as your diligence in following safety guidelines.

Before starting any job, go through a pre-start process and ensure everyone who is using power tools is trained and competent. And always check to make sure tools are in good working order.

Keep your hands and feet away from moving parts, keep others a safe distance away, and wear the correct personal protective equipment for the job.

Finally, employers and experienced workers need to ensure new and young workers receive the correct training and supervision.

Watch this short video by the Roofing Tile Association of Australia.

Your safety: it starts with you

Coming home safely to loved ones is generally everyone’s number one motivator to keep safe at work.

But it is all too easy to become blasé about workplace safety, believing the chances of being hurt are very slim.

Aside from the implications for employers – down time, low morale, and hiring and retraining a replacement – the consequences for the worker reach far beyond the workplace.

If lucky, an injured worker will be back at work within days, but if not, and recovery drags on – in some cases, indefinitely – the emotional and financial impact on their family can be devastating.

Life as they know it is never the same again and things normally taken for granted, such as walking the dog, driving a car, socialising or playing sport, may no longer be possible. Even what initially appears to be a minor injury sustained via a common workplace incident, a slip or trip, can have a major impact.

An arborist, for example, suffered a permanent and serious brain injury when he fell 11 meters to the ground while cutting a tree with a chainsaw.

A 49-year-old man suffered head, spinal and chest injuries when he fell three metres down a set of stairs on a Sydney construction site.

Another worker whose life will never be the same again, an 18-year-old labourer, sustained horrific injuries when a steel bar pierced his skull while he was operating an excavator on a Sydney demolition site.

All these incidents, like most workplace injuries, could have been prevented if the employers and workers had not let their guard down on work health and safety priorities.

No matter what you do, safety starts with you.

Watch this video.

Manage the risks of falls - or risk a fine

Over the past three years, most serious falls were from two to four metres – or about a single storey.

In November 2017, in response to alarming statistics regarding falls from heights, we introduced new on-the-spot fines – where employers can be fined up to $3600 for failing to control the risk of falls adequately – and launched a 12-month blitz on NSW construction sites.

Astonishingly, our inspections revealed more than 50 per cent of sites had unsafe scaffolding, more than 40 per cent didn’t have proper edge protection, and nearly 25 per cent didn’t provide a site safety induction to their workers.

Recently, a 20-year-old apprentice plumber died after suffering a broken neck and fractured skull when he fell six metres through a hole in a roof and landed on a steel beam. ‘In a spilt second your whole life changes forever,’ said his devastated aunt.

In another incident, a 67-year-old man sustained a traumatic brain injury, a fractured skull, collarbone and neck, and a punctured lung when he fell through an unprotected stairwell void on a Sydney construction site. He was in hospital for two months.

While working at heights is clearly a risky business, there are plenty of ways you can help avoid workplace tragedies and ensure your workers go home in one piece at the end of the day.

As with any high-risk activity, the best solution is to eliminate the need to work at heights where possible. If you can’t, you must provide a stable and securely guarded work platform or a suitable alternative.

Some typical examples are scaffolding, perimeter screens, guarding, fencing or other barriers capable of withstanding the loads that may be placed on it. Harness systems, such as fall restraint or fall arrest devices, should only be used as a last resort.

Last year and throughout 2019, our blitz on construction sites will continue. So, ensure you protect your workers – or risk a fine!

For more information on managing the risks of falls, visit our working at heights page.

If it's not safe, speak up!

One in 10 workers were too afraid to report safety issues because they might be fired and one in 20 have been demoted after making a safety complaint at work.

The survey also found that 37 per cent of workers have witnessed a colleague not reporting their injury at work for fear of losing their job.

Consultation is a good way to use the knowledge and experience of your staff to achieve a safer and healthier workplace.

Through talking about safety, you can become more aware of hazards in the workplace and workers can provide suggestions about how the work could be done safely.

This page outlines the basics of consultation at work and is available in Arabic, Mandarin, Cantonese and Vietnamese.

Let's talk safety in the supply chain

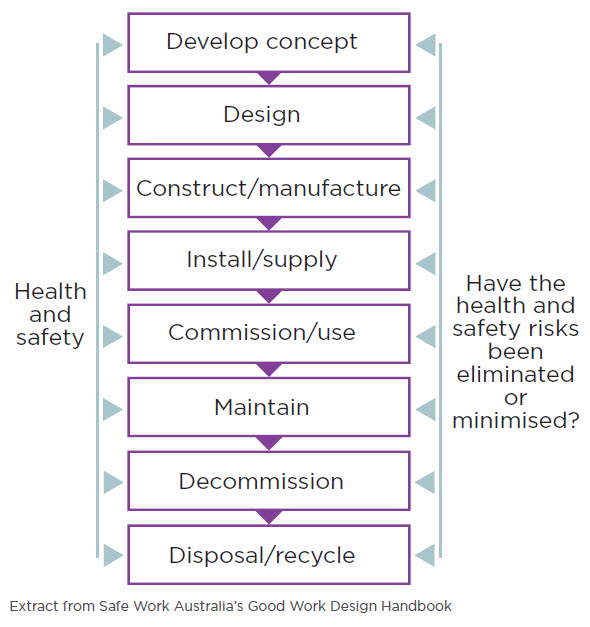

The transfer of work health and safety information in a supply chain includes identifying and controlling risks during the life cycle (including disposal) of buildings, products, substances, machinery and equipment. It includes transferring and consulting on work health and safety information to each of the duty holders during the design, production, supply and sale.

From 2018 to 2022 and beyond, we will work with industry to identify areas to influence the exchange of health and safety information.

Our strategy is to collaborate with industry and educate supply chain stakeholders of the role they can play in improving the exchange of safety-critical information.

We want to help you understand your responsibilities.

Together, we can educate everyone in the supply chain, and ensure the safe installation and supply of equipment and materials.

Tackling trees after wild weather

Determine the safest way to tackle the job

When you get to a new job, work out whether it is safer to work from ground level, to climb the tree, or to work from an elevated platform. If the weather or anything else changes, check the method you are using is still the safest one.

Inspect the tree

Check its condition before you start. In addition to any storm damage, look for signs of pest infestation, decay, dead wood and bark inclusions. A lack of foliage, soil movement, cracking at the base or a leaning tree could mean it has weakened or shifted roots and is unstable.

Inspect the site and your equipment

Check for hazards such as uneven ground, electrical lines, underground services, bad weather, nearby traffic, and people. Also check in on your own energy and alertness levels – fatigue and dehydration can be hazards too.

Inspect your machinery and climbing equipment before every use. If you are using wood chippers or stump grinders, it is particularly important that the emergency stops are working and workers are trained on how to use them. Make sure you mark exclusion and drop zones, that no one enters them, and that ground workers have an escape route.

Conduct a toolbox talk

All workers need to know what approach you will be using for the job and their role.

Train, equip and prepare your workers

Staff should always have the right protective gear, be fit for work, and not affected by drugs or alcohol.

Each year more than 150 people are seriously injured while doing tree work because of things like falls, working around power lines, working with equipment or being struck by falling objects.

By following the steps above, those helping our community clean up after the storms can plan to avoid injury and get home safe.

6 tips for a healthy workplace

Well, aside from a big morale boost, business benefits could be up to three times more productivity, less sick leave and fewer injuries. In a nutshell, a healthy workplace is very good for your business.

Research reveals healthy workers are fitter, more aware, alert and resilient against illness, and less likely to sustain manual handling injuries and strains.

While bigger businesses with more resources can afford to establish a formal health and wellbeing program, such an expense is probably a bit of a stretch for you. But fear not, there are still plenty of inexpensive things you can do to help make a difference.

Even small changes can have a huge impact, so here are six ideas:

- Target workers’ eating habits, especially if lunchtime fare is fast food high in saturated fats such as burger and fries. Install a larger fridge and an extra microwave so more staff can bring in meals from home to reheat – also saving them money.

- Offer more flexible working hours so workers go for walks, runs or swims, or attend a gym at lunchtime. Speak to a local fitness club about offering discount memberships for your workers.

- Print out simple exercise guides to place around the workplace.

- Establish a ‘break-out’ room where workers can make personal phone calls or have some quiet time.

- Help workers to quit smoking.

- Establish a workplace zero injuries target and promote this over one month, progressing to three then six months.

Get more great ideas about how you can help your workers get healthier and your business better.

Insider tips

In this feature, seasoned SafeWork inspectors, Anthony Nicholson and John Mizzi, provide helpful tips and pointers.

John: One catchphrase I often tell clients is that if it’s worth doing, then it’s worth documenting. Work health and safety laws don’t require employers to document day-to-day activities such as worker consultation or training for most workplace tasks. However, documenting these things, as well as risk assessments, provides evidence they have actually been done. So if an inspector responds to a particular health and safety issue, then the employer will be able to show they have addressed the issue by producing a supporting document. I advise clients to get safety messages over to workers by holding a toolbox talk and document it, using templates from our website.

Documenting a toolbox talk does not need to be complex. All you need to do is simply note the date, attendees and key messages discussed with workers.

Anthony: Some employers will spend a fortune hiring a consultant to develop a health and safety system or buying an off-the-shelf one. Often, these are generic and not directly related to a specific business. Honestly, the best systems are ones developed by a business in conjunction with workers. It’s not rocket science, just a method of delivering simple safety messages, information and support to workers.

John: If you are documenting training or safe work procedures and recording a worker’s name to confirm they’ve been trained, then they are also more likely to comply.

Anthony: The idea is to keep it simple and not to over-complicate it.

John: If you are unsure how to document a toolbox talk, and have 50 workers or less, then call SafeWork and request a free workplace advisory visit. An inspector will happily show you how to do it and even provide the templates.

Anthony: All it costs employers is some commitment and their time.

John: Plus small employers who request an advisory visit are eligible to apply for a small business rebate for the purchase of equipment or solutions they buy to improve workplace health and safety.

Find out more about our small business rebate program and search for ‘templates’ on our website.

Solvents can affect your memory

Author Erika L. Sabbath said the findings were significant as workplace exposure to solvents was extremely common and posed a real risk both in the present and the future.

“And as retirement ages go up, the length of time that people are exposed is going up, too,” Dr Sabbath said.

Chlorinated solvents can be found in dry cleaning solutions, engine cleaners, paint removers and degreasers, while petroleum solvents are used in carpet glue, furniture polishes, paint, paint thinner and varnish.

Researchers assessed the lifetime exposure of 2143 retirees, as well as their last exposure to chlorinated solvents, petroleum solvents, and benzene, which is used in synthetics manufacturing.

Participants took eight memory and thinking skills tests 10 years after they had retired at an average age of 66.

Researchers found those with high and recent exposure at the greatest risk for memory and thinking deficits regardless of other factors, such as education levels, age, smoking and alcohol consumption.

Dr Sabbath, of the Harvard School of Public Health in Boston, said retirees with high exposure within the past 12 to 30 years had demonstrated impairment in virtually all areas of memory and thinking.

For more information about using solvents, visit the hazardous chemicals page.

10 things you should know

Here are 10 things you can do that will help your business comply with work health and safety regulations and keep your team safe.

- Get a workers compensation policy if you need one.

- Talk about safety and get input from your workers.

- Make sure everyone is properly trained and understands how to do their work safely.

- Establish safe working procedures.

- Provide adequate workplace facilities.

- Use personal protective equipment if no other controls are available.

- Record any workplace injuries in a register.

- Notify us of serious incidents.

- Have a recover at work program

- If in doubt, ask for help – give us a call on 13 10 50.

Work health and safety made easy

We have developed the ‘Easy to do work health and safety toolkit’ to make it easier for small businesses to understand and meet their work health and safety obligations. Check it out today.

6 ways to stay safe

Store and handle chemicals properly at all times.

Depending on the quantity and type – paint, glue, cleaning agents, fuel, pesticides or solvents – the consequences could be catastrophic.

Not only could your workers be exposed to harmful fumes or toxins that may cause chronic illnesses such as cancer or asthma, but leaks or spills can cause costly environmental damage such as water contamination.

Unchecked, a gradual-release or prolonged exposure could come years down the track, via financially crippling legal action by affected workers or environmental watchdogs.

Some potential hazards might not be obvious, such as a spray painter working in a booth listening to a portable radio – a possible ignition source for flammable fumes.

Often the risk has never occurred to them because it’s how they’ve always done it or been told how to do it. And unfortunately it’s often only when an accident does occur that the penny drops.

SafeWork Assistant State Inspector

Aside from the risk of an explosion or violent chemical reaction, simply inhaling vapours could render your workers drowsy and more likely to make errors or suffer an injury.

Here are some pointers.

- Make sure chemicals delivered to your workplace are clearly labelled.

- Make sure workers understand safety data sheet and labels.

- Make a list of all your hazardous chemicals – and always keep it up to date.

- Isolate hazardous chemicals from the rest of the workplace, restrict access to dangerous areas, and use exhaust ventilation for fumes.

- Develop an emergency plan and provide appropriate personal protective equipment.

Exercise helps prevent depression

The results show even small amounts of exercise can protect against depression, with mental health benefits seen regardless of age or gender.

The study involved more than 30,000 adults who had their levels of exercise and symptoms of depression and anxiety monitored over 11 years.

The study found that 12 per cent of cases of depression could have been prevented if participants undertook just one hour of physical activity each week.

According to an Australian health survey, 20 per cent of Australian adults do not undertake any regular physical activity, and more than a third spend less than 1.5 hours per week being physically active.

At the same time, around 1 million Australians have depression, with one in five Australians aged 16-85 experiencing a mental illness in any year.

To improve your physical and mental wellbeing through exercise, see the institute’s Exercise your Mood campaign.

Understanding workers compensation

The workers compensation process can be complex – and this complexity is amplified when you have limited claims management experience, resources and cash flow.

For most small businesses, a workers compensation claim may only occur once every several years. Many employers pay their annual premium and have no further contact or relationship with their insurer.

A challenge for small businesses is the number of stakeholders involved with the workers compensation process, and the various relationships that exist between these stakeholders.

This seminar features three panel members representing the employer, insurer and regulator. They discuss the role of each in the workers compensation process, the supports available for business – eg vocation rehabilitation and work trials – and the recovery at work programs run by the State Insurance Regulatory Authority (SIRA).

SIRA has also developed a tool that helps injured workers understand their weekly payments and entitlements at different stages of their claim.

SafeWork licence register: making it easier to do business

Following an amendment to the WHS Regulation, the NSW Government published a register of individuals who hold asbestos, high risk work and demolition licences as well as holders of general construction induction training cards (otherwise known as white cards).

The register includes the licence holder’s name, licence number and type, the licence status, the licence expiry date (if any), licence conditions, prosecution summaries and information about penalty notices issued in connection with the licence.

The register enables better protection for workers and the community by providing licence information via a single online portal, and makes it easier for businesses and consumers to check the validity of the licences/cards and make informed decisions regarding the contractors they engage.

The changes are consistent with the NSW Government’s objective to provide a single and accountable point for the administration of business regulation schemes, which in turn provides greater business confidence while maintaining appropriate levels of consumer protection.

Do you get enough sleep?

Train drivers, waiters, chefs, and shift workers in manufacturing and healthcare are most likely to suffer the greatest sleep deprivation.

Shift work, job stress, work hours and physically demanding work are also linked to sleep deprivation. Round-the-clock access to technology and pressure to work harder has increased work hours and led to an increase of short sleep.

If it’s not safe, speak up!

A recent survey of more than 2000 workers found that one in five have made a complaint about a workplace safety issue that was never fixed.

One in 10 workers were too afraid to report safety issues because they might be fired and one in 20 have been demoted after making a safety complaint at work.

The survey also found that 37 per cent of workers have witnessed a colleague not reporting their injury at work for fear of losing their job.

Consultation is a good way to use the knowledge and experience of your staff to achieve a safer and healthier workplace.