Managing extreme heat at your workplace

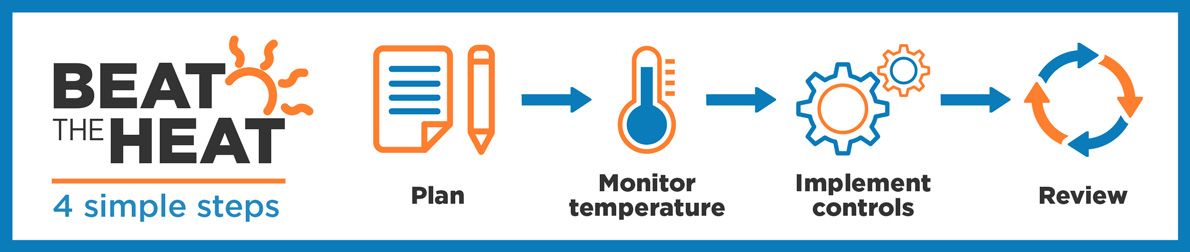

If extreme heat is a hazard in your workplace, it should be managed following the standard risk management approach:

- Identify the hazard

- Assess the risks

- Control the risks

- Review control measures.

Workers and their HSRs must be consulted at each step of the process.

Step 1: Is heat an issue in your workplace?

Extreme heat can impact people working in both indoor and outdoor environments. Your workplace might be particularly susceptible to heat-related problems if you answer ‘yes’ to one or more of the following questions:

- Has anyone ever been affected by heat in your workplace?

- Can workers be exposed to temperatures that exceed 300C and/or high humidity?

- Is there any plant or equipment that produce heat or steam?

- Do any work processes make the surroundings hotter?

- Are there any areas of the workplace that are particularly hot?

- Are there surfaces or equipment that produce, radiate or reflect heat and/or UVR?

- Do workers wear protective clothing/ personal protective equipment (PPE) that can make them hot?

- Are workers engaged in physical tasks (including prolonged standing)?

- Are any work areas poorly ventilated with little airflow?

- Can hot air build-up in the workplace over successive hot days?

- Are there any barriers/ structures within the workplace preventing crossflow?

- Can it ever be hotter inside the workplace than it is outside?

- Can it ever be more humid inside the workplace than it is outside?

- Are any non-insulated walls/ ceiling spaces of the workplace exposed to direct sunlight?

- Are workers working outdoors when the UV Index is 3 or above?

Step 2: Assess the risks

If exposure to extreme heat is identified as a risk, you should assess the level of risk.

In consultation with workers and/or their HSRs, you should conduct a risk assessment of extreme heat risks to determine:

- the severity of the risks

- whether any risks can be eliminated

- whether any risks can be minimised

- if existing control measures are effective

- the actions to be taken to control remaining risk, and

- how urgently you need to act.

Your risk assessment must consider the environmental factors, such as the air temperature, humidity, amount of air movement and radiant temperature of the surroundings as well as the personal factors of the workers, such as clothing worn, physical activity being done and their physical fitness. Also consider tasks involving working with hot materials and jobs that have to be done quickly.

PCBUs must consider all these factors and eliminate the risks, so far as is reasonably practicable. In some circumstances, during the consultation process with your workers and/or their HSRs, agreement may be reached on specific parameters for extreme heat conditions when work will be stopped to eliminate the risk. All agreed parameters should be included into your workplace heat management plan.

PCBUs should also develop suitable systems in consultation with workers and/or HSRs to undertake:

- regular workplace environmental heat risk indicator monitoring (such as temperature and humidity), and

- formal workplace heat stress assessments when necessary (of both environmental and personal factors by a suitably qualified occupational hygienist)

These details should also be included into your workplace heat management plan.

Step 3: Control the risks

You must eliminate the sources of extreme heat in your workplace, so far as is reasonably practicable. If you can’t, you must reduce extreme heat risks by following the hierarchy of control.

It’s important that you don’t rely on the administrative controls and PPE. These should only be used to supplement higher order controls such as isolation and engineering. Usually, a combination of controls is needed to get the best results and any control measures must be determined in consultation with your workers and/or HSRs.

In consultation with your workers, control the hazards using the hierarchy of control.

Find more information on how you can follow the hierarchy of controls to reduce the risk of extreme heat in your workplace under the headings below.

Level 1: Eliminate the risk

Eliminate the hazard

It may not be possible to change the environmental conditions, but you can eliminate worker exposure to extreme heat. Consider whether the work can be done at an alternate time or place to remove the work away from the risk. If not, consider what Level 2 controls may be possible.

Designing better work systems and workplaces

Workplaces and work tasks should be designed and built with health and safety in mind – for both indoor and outdoor work.

The best control is to eliminate extreme heat hazards at the design or planning stage of work systems, or the construction or renovation of a workplace.

Eliminating hazards at these stages is often easier and cheaper to achieve than making changes later when the hazards become real risks in the workplace.

To eliminate risks of exposure to extreme heat when designing a new indoor workplace – particularly those that will be without air-conditioning – you should:

- ensure construction materials used for walls and roofs reduce or eliminates heat build-up and dissipation inside the workplace.

- incorporate good air flow for all work areas (e.g. via windows, shutters or roof design)

- incorporate suitable structural insulation to protect persons against extreme heat (and cold)

- ensure the selection and positioning of heat generating plant and equipment reduces or reduce or eliminates heat build-up and dissipation inside the workplace

- consider the velocity and direction of hot air (natural and artificial), including air movement from any heat generating plant and equipment; open windows and doors; and open delivery areas. Also consider potential for air flow within a workplace to be blocked or obstructed (e.g. from deliveries received, delivery vehicles, etc.)

Level 2: Isolate the risk

Isolate the hazard

Examples:

- start work on the shady side of the building, and follow the shade around the building as the day progresses

- isolate workers in air conditioned control rooms away from the hot work environment

- locate hot processes away from people

- enclose or insulate hot processes, hot surfaces and around heat generating plant, equipment and pipes

- install shields, barriers or guards to isolate radiant heat sources, such as ovens, furnaces, etc

- isolate heat-producing equipment to limit exposure to radiant heat

- insulate buildings and clad sources of radiant heat

- where possible, relocate workstations away from hazard areas, such as direct sunlight via windows or skylights

Engineering controls

Examples:

- provide air-conditioning. Whatever type is used, make sure:

- there is adequate air flow. Feelings of stuffiness can result when air flow is low, and draughts result when air flow is high

- the direction of air flow is satisfactory so that the air flow reaches all areas in the workplace

- the thermostat is not situated directly in front of a vent

- the air-conditioning unit is regularly serviced and maintained, so it does not break down in the middle of a heat wave

- install local mechanical exhaust ventilation to increase air movement and remove hot or heated air/ steam from hot plant, processes and areas where heat can build up or where there is little air movement

- provide air-conditioned cabins in cars, mobile plant and other equipment

- provide evaporative coolers

- use chiller units, in extreme cases, to relieve air temperature and humidity (e.g. when working in confined spaces)

- install reflective or light-coloured external wall cladding and roofing to the building

- place reflective shields or coatings on radiant heat spots

- install blinds, louvres, awnings, screens, window tinting treatment, reflective film to windows or skylights to control exposure to direct and indirect sunlight

- ensure windows can be opened, where practicable

- provide fans to increase air movement (consulting with an airflow expert may be necessary to ensure effectiveness of banks of fans)

- provide mechanical equipment to reduce the need for strenuous physical work

- provide screens, umbrellas, canopies or awnings over sections of the site to create shade where work is being carried out

- provide suitable communication systems that function in black spots, and remote and isolated areas (e.g. mobile telephone, satellite phone, personal duress alarm, emergency beacon)

- provide suitable technology and other tools to help overcome the hazards faced by isolated and/or solitary workers.

Level 3: Administrative controls, training and PPE

Administrative controls

Administrative controls should only be used to provide a systematic framework to support the higher controls that you have implemented.

Administrative actions may include:

- monitoring environmental conditions, particularly during summer, and when hot weather and heatwaves are forecasted, to help identify and assess the risks of exposure to heat-related illness. Include in your heat management or monitoring plan, testing of different areas including work at different heights – if work at heights is required in the workplace.

- ensure workers are acclimatised. Ease new workers into a hot workplace gradually, allocate extra breaks and slowly increase their workload.

- limit work in "hotspots" of the workplace to only cooler parts of the day

- as people experience heat differently, flexibility should be provided with dress codes as so workers can adapt conditions according to their individual need. Allow for the removal of tights, ties and jackets or other extra clothing unnecessary for safety.

- ensure uniforms are layered, made of breathable fabric that is suitable for the environment and the task

- provide cooling vests for workers to wear in extreme situations

- provide easy access to cool drinking water and encourage workers to drink often

- provide access to crushed ice (to ingest and for use as ice towel) where possible

- provide regular and frequent breaks away from hot work areas and processes in air-conditioned or cool, well-ventilated areas

- ensure the first aid room is air-conditioned, where relevant

- ensure appropriate number/s of trained first aiders who know how to deal with heat-related illness are rostered on all shifts

- provide suitable supervision of all workers. If they must work alone, monitor them and ensure they can easily call for help

- implement an effective ‘buddy system’ where workers check each other frequently

- implement effective communication procedures to ensure regular contact with staff working alone

- organise work to minimise physically demanding tasks

- ensure the work is paced to meet the conditions

- some medications can affect the user’s ability to cope with heat. Ensure you make adequate adjustments for workers that are impacted by this.

- increase worker rotation so the same workers are not always exposed to extreme heat

- reduce the length of shifts

- ensure all plant and equipment are regularly inspected, serviced, and maintained

- monitor the effectiveness of the controls you currently have in place

Information and training for workers

Suitable information and training must be provided to all workers – regardless of whether they are full time, part-time, casual workers, shift workers, labour-hire workers, or contractors.

Ensure the information and training is understood by all workers – including those from culturally and linguistically diverse (CALD) backgrounds.

The training content should detail:

- what the heat management plan is for hot days

- who the designated person/s are with responsibility to monitor heat and humidity, especially when extreme heat days are forecast

- how to identify heat hazards in the workplace

- how to work safely in the heat

- how to recognise warning signs and symptoms of heat-related illness in themselves or their co-workers; how to respond to them; and when to call for assistance

- how to avoid experiencing heat-related illness

- what to do in an emergency, such as a worker experiencing severe heat-related illness

- how to report heat-related illness incidents

- that personal factors can increase the risk of exposure to heat-related illness (e.g. clothing, hydration, general health, physical fitness, pregnancy, use of some medications, drugs and alcohol)

- not to replace drinking water with energy drinks, soft drinks or coffee

- the control measures you have in place to manage the heat risk

- how to use and wear PPE correctly and how to dress for hot conditions. Include any restrictions on personal clothing that can be worn underneath protective clothing

- to consult with their doctor if they have any health concerns.

Personal protective equipment (PPE)

PPE is the last and least effective control in the hierarchy and should only be used to manage any risk that is leftover after all higher-level controls have been implemented, so far as is reasonably practicable.

Wearing or using different types of PPE does not eliminate or minimise any risk – it acts only as a barrier between the risk and the worker.

Workers who need to wear or carry PPE in hot work environments can be at greater risk of exposure to heat-related illness because it can increase the body’s heat load. Wearing protective clothing (such as aprons, overalls and face masks) may also increase the risk of workers being exposed to heat-related illness.

Where relevant, ensure a workplace policy is developed in consultation with workers and/or their HSRs stating what personal clothing can be worn underneath relevant items of protective clothing, so it doesn’t increase the risk.

Where PPE is provided for workers exposed to extremes of heat, make sure:

- it is necessary

- it is made of suitable material / fabric that is designed to keep you cool in a hot work environment without causing a secondary risk

- it is comfortable to wear, allows free movement of air and sweat evaporation

- it is compatible to use with necessary equipment and other PPE

- that workers are wearing it correctly and that they are not wearing more PPE than is required

- appropriate rest/work ratio is implemented

- rostering during cooler parts of the day, where possible

- work load/rate is reviewed and managed.

Developing a workplace heat management plan

To effectively manage risks of exposure to heat-related illness, we recommend a workplace heat management plan is developed and implemented in consultation with workers and/or their HSRs.

The plan should include suitable systems to:

- undertake regular workplace environmental heat risk indicator monitoring

- designate person/s responsible for monitoring workplace heat and humidity, especially in summer and during forecast extreme heat weather

- identify when formal workplace heat stress assessments are necessary (measuring both environmental and personal factors by an occupational hygienist with skills in assessing thermal conditions)

- detail the agreed controls to be implemented, when they should be implemented and who is responsible for implementing them

In some circumstances, during the consultation process with your workers and/or their HSRs, agreement may be reached on specific parameters for extreme heat and other conditions when work will be stopped to eliminate the risk. All agreed parameters should be included into the workplace heat management plan.

Wet Bulb Globe Temperature (WBGT) monitoring is used to undertake formal workplace heat stress risk assessments

Traditionally WBGT monitoring over full work shifts is used to fully assess workers’ risk of exposure to heat-related illness in high risk, complex and/or contentious situations.

WBGT monitoring establishes a clearer picture of all the contributing factors (both environmental and personal) that can impact exposed workers to the risk of heat-related illness – and the results should be recorded as part of the workplace heat management plan.

It requires the services of an occupational hygienist who has:

- skills in assessing indoor thermal conditions and air quality, and

- an appropriate level of technical expertise to measure, interpret, evaluate and report the data.

The occupational hygienist's expertise will also assist with identifying if:

- work-rest schedules should be established

- an acclimatisation program needs to be developed.

Appropriate control measures can then be developed in consultation with affected workers and/or their HSRs.

Step 4: Review controls

Regularly review the controls outlined above in step 3 to ensure their effectiveness. The review process should also be included into your workplace heat management plan.

Other important facts

If a worker thinks their workplace is too hot, they should report it.

If a worker is concerned that they are working in an unsafe hot environment, they should alert their immediate supervisor to the problem and discuss some of the possible ways of reducing the impact on themselves and their co-workers.

If the supervisor will not deal with the problem or the worker believes the problem hasn’t been fixed, they should contact:

- the Health and Safety representative (HSR), if there is one. Trained HSRs have the power to order work to stop if they deem the risk is so serious that it's unreasonable to address the issue via the usual workplace consultation process

- the supervisor’s manager.

If the matter is still unresolved and the worker continues to believe that an unsafe situation exists, they should contact SafeWork NSW on 13 10 50 for further advice.

If a worker has a reasonable concern that the work would expose them to a serious risk to their health or safety, from an immediate or imminent exposure to a hazard, they may choose to cease, or refuse to carry out, the work.

Any worker who ceases work due to their reasonable concerns must:

- notify the PCBU that they have ceased work as soon as practicable (unless the worker ceased work under a direction from a health and safety representative) and

- remain available to carry out suitable alternative work.

Online tools and apps

Heat Stress Calculator

Anyone with basic knowledge of the work area and process can use this online tool as a basic guide to help identify and manage risks of heat related illness. It can also be used as a training tool.

Go to the Heat Stress Calculator

The Bureau of Meteorology Heatwave Service for Australia

This page provides information on heatwaves coming up across the state, and the severity of the heatwave expected. Check this page regularly to see if your work location is in the zone, and take action.

Go to the BOM Heatwave Service

The Predicted Heat Strain app (PHS)

This app requires more detailed information to be entered about the working environment, the work task and the individual worker. It then to evaluates the work scenario’s potential risks and controls, and predicts the core body temperature and water loss assessment.

Search PHS on your app store to download for free.

The Cancer Council SunSmart app

This app enables people to find out the specific “Sun Protection Times” for each day. It can be set to the location where the work is being done and advise the actual timeframe that sun protection is required to be used on that day in that place.

Search SunSmart on your app store to download for free.

Safe Work Australia

Safe Work Australia have a range of resources available on their website about working in heat - including videos, fact sheets and guidance material.

Further information

- Managing the work environment and facilities Code of Practice (PDF, 422.29 KB)

- Work health and safety consultation, coordination and cooperation Code of Practice (PDF, 635.62 KB)

- Safe design of structures Code of Practice (PDF, 1039.8 KB)

- Safe Work Australia (SWA): Guide for managing the risks of working in heat

- Cancer Institute NSW: NSW Skin Cancer Prevention Strategy

- Cancer Council NSW: Shade and UV protection

- Australian Institute of Occupational Hygienists: Basic Thermal Risk Assessment Tool

- Australian Standard AS1668: The use of ventilation and air conditioning in buildings

- ISO 7243 (2017) Ergonomics of the thermal environment – Assessment of heat stress using the WGBT (wet bulb glob temperature) index