Identify health and safety risks

You must find out what your health and safety risks are, particularly those that could cause harm to your workers.

It’s important to understand that risks are caused by hazards or situations in the workplace.

To find hazards take regular walks around the workplace and look out for potential hazards including:

HAZARD | RISK | |

|---|---|---|

Type of hazard | Example of hazard | Example of harm caused |

Manual tasks | Heavy lifting, repetitive movement | Muscular strain |

Electricity | Working with live electricity | Shock, burns or death |

Machinery | Blade, conveyor belt, auger | Lacerations, crushed or loss of limbs |

Tools | Knife | Cut |

Working at heights | Ladder, scaffolding | Broken bones from falls, death, permanent disability |

Ergonomic | Desk height set incorrectly | Neck or back pain |

Hazardous chemicals | Exposure to toxic chemicals | Illness, disease and death |

Extreme temperatures | Exposure to adverse weather, hot or cold environments | Dehydration, heat stroke, frost bite |

Noise | Prolonged exposure to noisy machinery | Permanent hearing loss |

Radiation | Exposure to ultra violet light, welding arc flashes, microwaves and lasers | Burns, cancer or blindness |

Biological | Exposure to blood or bodily fluids | Disease, skin allergies, irritations |

Psychosocial | Bullying, stress, fatigue | Anxiety, depression, mental health issues |

Housekeeping | Untidy work area or floor space | Slips, trips and falls |

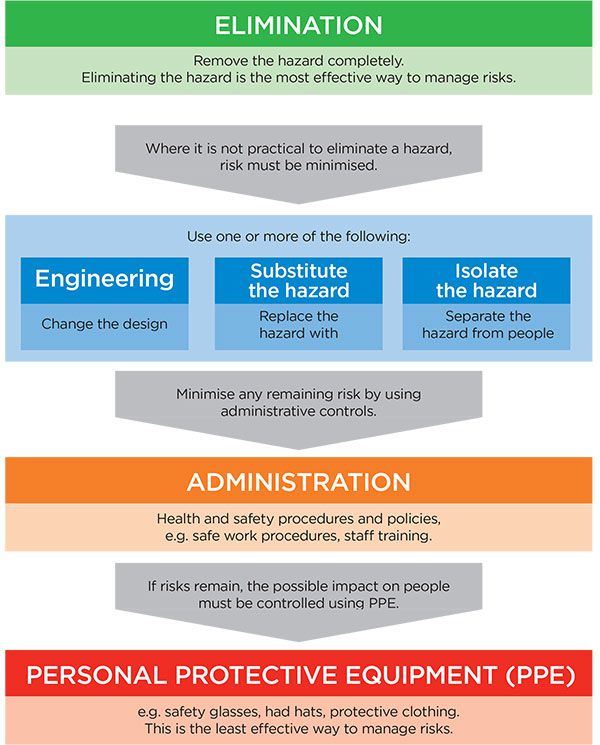

Control measures

Use the right controls to eliminate or minimise risks and protect your workers.

Regularly review your risks and controls

Controlling risks is an ongoing process that must be reviewed regularly. Review and, if necessary, revise control measures when:

- an incident occurs

- the control measure is not working

- a new risk or hazard is identified

- consultation suggests a review is necessary

- workplace changes - eg planned changes to layout or equipment

- a health and safety committee requests it

Set up a process to manage your controls and educate your workers. This is called a health and safety system and includes a combination of safety procedures, training for workers, and/or warning signs for hazards.

You must involve your workers at each step of the risk management process. By using the experience, knowledge and ideas of your workers, you are more likely to find safety issues and choose better control measures.

Design tasks and the use of equipment to be safe

When designing tasks and processes, give your workers:

- manageable workloads

- reasonable hours

- appropriate duties - eg avoid excessive manual handling or repetitive tasks

When using new equipment, make sure:

- the item is fit-for-purpose

- equipment is safely guarded

- it is stored correctly

- workers know how to use it safely

- you get safety data sheets and operating manuals from your designers, manufacturers, importers and suppliers

To avoid problems, talk to experienced workers before you buy new machinery and equipment. For more information, see ‘safe working environment’.